- Stock: Inquire availability

- Product code: 00-00013369

- Shipping Weight: 49.50kg

This offer ends in:

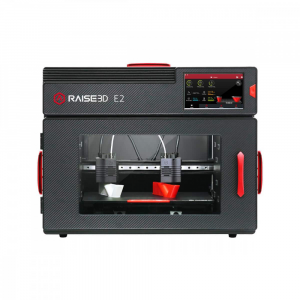

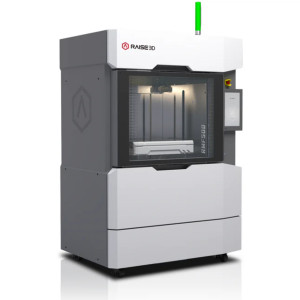

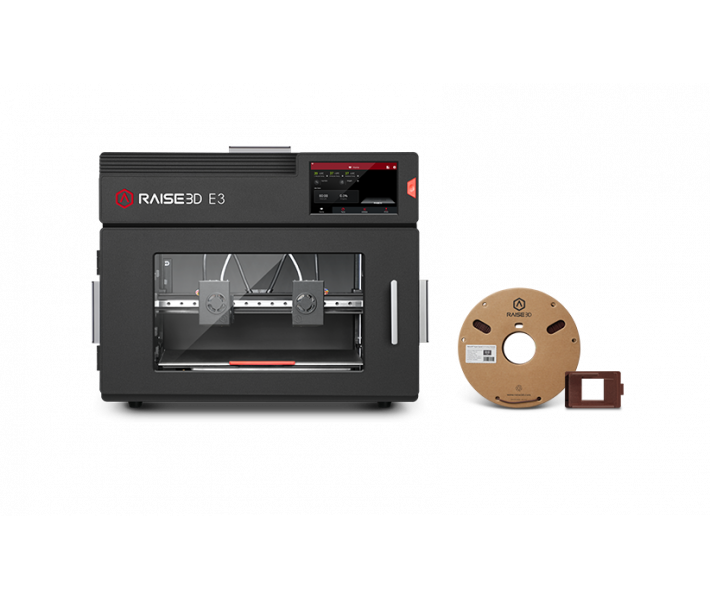

Raise3D E3 - The Professional Standard of Precision and Efficiency in 3D Printing

Additive manufacturing technologies have moved far beyond the experimental stage and are now firmly established as integral tools in industrial production. Modern enterprises, engineering firms, and research institutions demand from 3D printers not only exceptional precision but also reliability, repeatability, and flexibility in handling a wide range of materials.

In this context, the Raise3D E3 stands out as a professional FFF 3D printing system designed to combine productivity, quality, and technological versatility. The manufacturer positions this model as a next-generation solution engineered for continuous, high-performance printing with technical thermoplastics, flexible filaments, and composite materials.

Advantages of Raise3D E3

Support for Flexible and Composite Filaments

One of the key advantages of the E3 is its ability to print with flexible materials such as TPU at high speeds - up to 200 mm/s when equipped with the Flexible Filament Auxiliary Feeder.

This capability enables the creation of elastic components, damping parts, and flexible prototypes without compromising quality or efficiency.

Additionally, the printer supports composite filaments (for example, fiber-reinforced plastics such as PET CF, PET GF, and PPS CF). This allows engineers to produce durable, functional components with superior mechanical properties.

In short, the Raise3D E3 is a versatile tool that can handle both soft, elastic prototypes and reinforced structural elements with equal reliability.

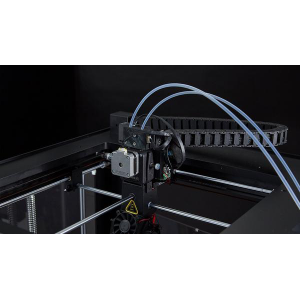

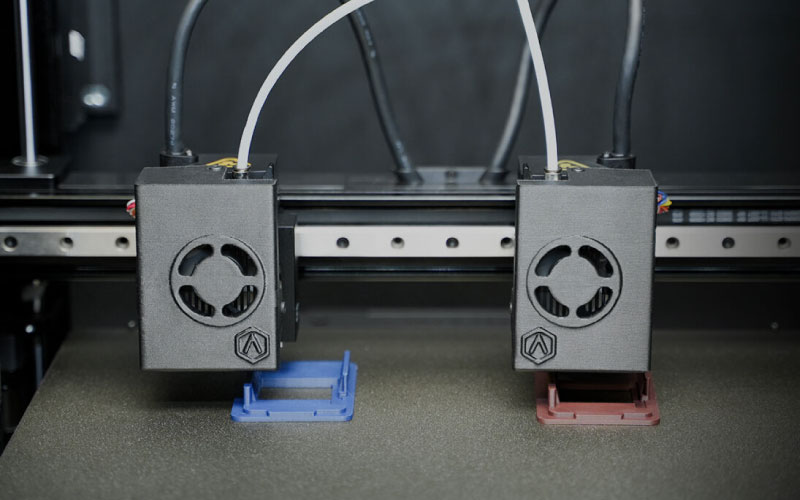

IDEX System: Parallel and Mirror Printing

The Raise3D E3 features an IDEX (Independent Dual Extruder) system, allowing the two extruders to operate independently. This opens several highly practical print modes:

- Duplicate Mode: prints two identical models simultaneously, effectively doubling productivity for batch manufacturing.

- Mirror Mode: prints mirrored versions of a part, ideal for producing symmetrical components.

- Dual-Color / Dual-Material Mode: enables printing with two different filaments, even with distinct temperature settings, making it suitable for complex, multi-material assemblies.

This architecture significantly enhances production efficiency and creative freedom - without the need for a second printer.

Reliability for Long-Duration Projects

Raise3D has equipped the E3 with a suite of reliability features designed for continuous, unattended operation — essential for extended print jobs:

- Filament Run-Out Sensors: automatically detect when filament is about to run out, pausing the print and alerting the user.

- Power-Loss Recovery: in the event of a power interruption, the printer saves its exact position and resumes printing seamlessly once power is restored.

- Dual Material Storage Slots with Desiccants: keeps filaments dry and prevents print defects caused by humidity or moisture absorption.

These safeguards minimize downtime, ensure consistent quality, and reduce material waste - critical benefits in production environments.

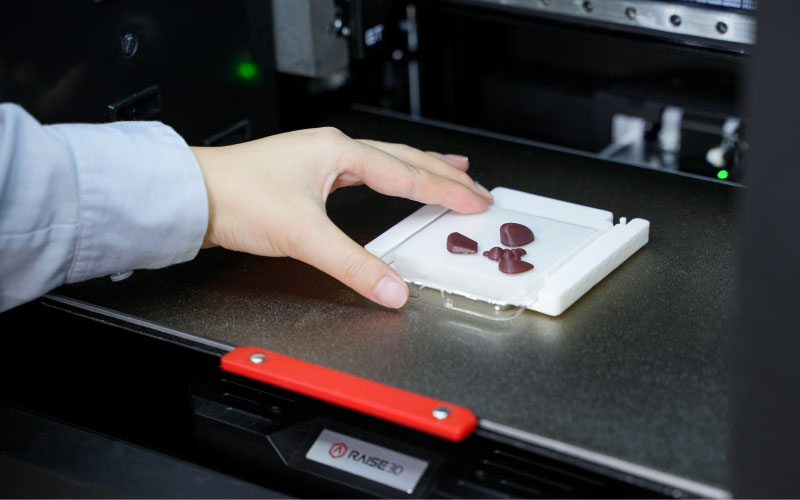

Ease of Use: Auto-Leveling and Substrate Printing

The Raise3D E3 incorporates several intelligent automation features that simplify setup and enhance reliability:

- 9-Point Auto Bed Leveling: precisely calibrates the build surface, improving first-layer adhesion and reducing setup time.

- Substrate Printing Support: enables printing directly onto flat substrates, expanding creative flexibility for specialized applications and material testing.

Such features streamline workflow, reduce human error, and allow users to focus more on design and less on manual calibration.

Superior Surface Quality with Pro Ironing

Raise3D emphasizes the Pro Ironing function, which delivers exceptional surface finish comparable to molded parts — particularly when paired with Hyper Speed PLA Pro or other Raise3D filaments.

According to the manufacturer, this process achieves a surface roughness (Ra) of less than 2 microns, producing remarkably smooth results.

This capability is especially valuable for applications where appearance matters — such as design prototypes, molds, or consumer-facing components that require minimal post-processing.

Open Material Program (OMP)

The Raise3D Open Material Program (OMP) provides users the freedom to choose from a wide variety of filaments beyond the manufacturer’s proprietary range.

This open approach enhances flexibility, helps optimize cost-to-performance ratios, and prevents dependency on a closed ecosystem - a significant advantage for professional users managing multiple materials and suppliers.

Where the Raise3D E3 Excels

The E3 is designed to perform reliably across diverse environments - from research labs to small-scale production. Here are several typical use cases:

High-Precision Prototyping

In design studios or R&D departments that require fast, accurate prototypes for fit, form, and function testing, the E3’s combination of flexible material support and Pro Ironing surface refinement delivers consistent, professional-grade results.

Small-Batch Production and Spare Parts

For businesses producing customized components - such as brackets, casings, or assembly fixtures - the IDEX Duplicate Mode effectively doubles throughput, making low-volume manufacturing faster and more economical.

Flexible and Elastic Components

When producing soft parts like gaskets, damping elements, or sports equipment components, the E3’s flexible material feeder allows reliable, high-speed printing with TPU and similar elastomers.

Educational and Research Institutions

In universities, technical labs, or FabLabs, the E3 offers a broad learning and experimentation platform. Its support for rigid, flexible, and composite materials enables students and researchers to work with diverse polymers using a single, dependable system.

Design Studios and Artistic Applications

For designers and artists, the combination of Pro Ironing and substrate printing unlocks new creative possibilities. Smooth, visually appealing surfaces can be produced directly, while substrate support allows innovative textural or mixed-media projects.

Raise3D E3: A Reliable, Versatile, and Professional-Grade Solution

The Raise3D E3 combines power, flexibility, and reliability in one professional 3D printing platform. Without overcomplicating the workflow, it provides users with a comprehensive set of advanced tools:

- High-speed printing with flexible and composite materials.

- IDEX system for parallel, mirrored, and dual-material printing.

- Robust safety and continuity features (filament sensors, power-loss recovery).

- Simplified setup with automatic bed leveling and substrate printing.

- Open Material Program compatibility for maximum material choice.

This printer is ideally suited for companies integrating 3D printing into production workflows, as well as for laboratories and R&D teams that value precision, consistency, and adaptability.

For professionals seeking a reliable, production-ready system that combines industrial performance with creative versatility, the Raise3D E3 represents a new benchmark in professional 3D printing.