- Stock: In Stock

- Product code: 00-00000143

- SKU: F4-RPS-MKIT-01

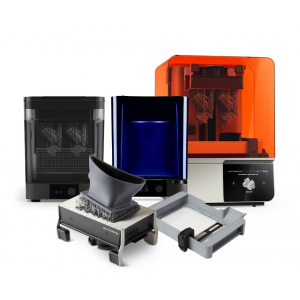

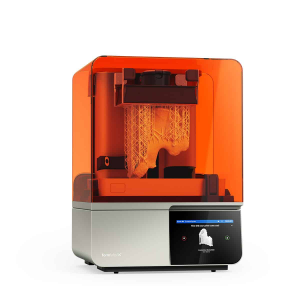

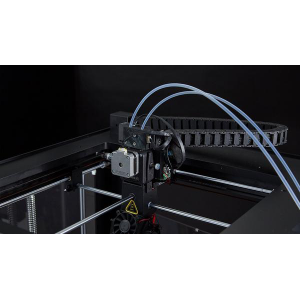

Replacing tube for Formlabs Form 4 Resin Pump

Printing on a 3D printer with polymer resin will be of higher quality if the printing system is properly maintained. Replacing the tube in the Formlabs Resin Pump for photopolymer printing should be done regularly.

It is necessary in case of physical damage or when changing the printing material. Scheduled replacement is performed every 6 months of printing. The manufacturer offers a repair kit consisting of an internal pump tube and a transfer tube that connects the pump to the resin container.

Thanks to the complete compliance of the kit parameters, replacement does not cause difficulties even for beginners. 3D printing in medicine is largely done with resins. For the best quality of products and a long service life of the printer, do not forget to regularly replace the resin supply tubes.

Why is it important to regularly change the resin tube in your Formlabs Resin Pump?

Maintaining print quality and printer performance

Regularly changing the resin tube in your Formlabs Resin Pump is critical to maintaining high print quality and the smooth operation of your Form 4 3D printer. Here’s why:

- Material wear: The tube that is constantly in contact with the resin is subject to wear. Over time, micro-cracks can form on the inner walls, causing the passage diameter to become smaller. This, in turn, can lead to clogging, uneven resin flow, and poor print quality.

- Resin contamination: Resin particles deposited on the tube walls can contaminate the fresh resin in the reservoir. This can cause changes in the properties of the resin and imperfections in the finished product.

- Deteriorating vacuum seal: Wear and tear on the tubing can compromise the vacuum seal of the system, causing resin leaks and poor print quality.

- Decreasing pump performance: A clogged or damaged tubing will increase the load on the pump, which can lead to premature wear and failure.

Formlabs Resin Pump tubing replacement recommendations

Formlabs recommends replacing the resin tubing every 6 months, or sooner if you notice deteriorating print quality or other resin flow issues.

Signs that the tubing needs to be replaced

- Deteriorating print quality: Surface defects such as layering, pores, or uneven filling of parts.

- Slower print speed: If the print process takes longer to complete, there may be a problem with the resin flow.

- Resin leakage: Resin residue on the tubing or connections.

- Unusual pump noises: Loud noises or vibrations may indicate a problem with the pump or tube.

Regularly replacing the resin tube is a simple procedure that will help maintain high print quality, extend the life of the printer, and avoid unexpected problems. Following the manufacturer’s recommendations will ensure trouble-free operation of your Form 4 3D printer.

Important note: Always use genuine Formlabs parts to ensure maximum compatibility and longevity of your system.