- Stock: Out of stock

- Product code: 00-08800469

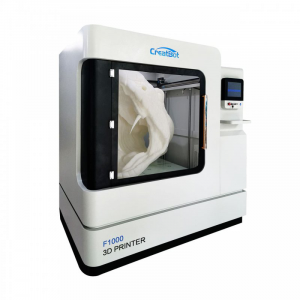

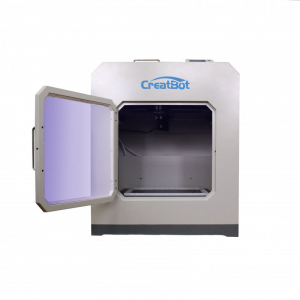

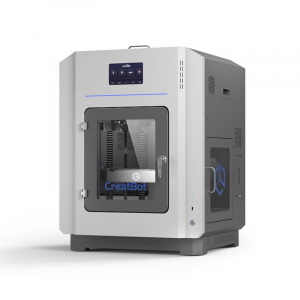

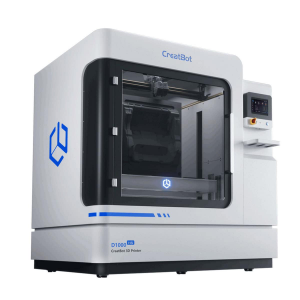

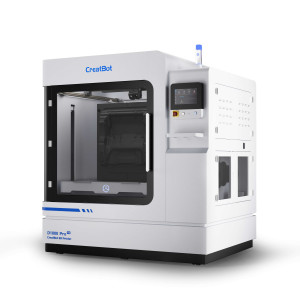

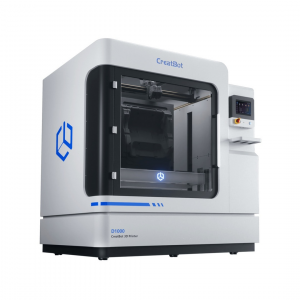

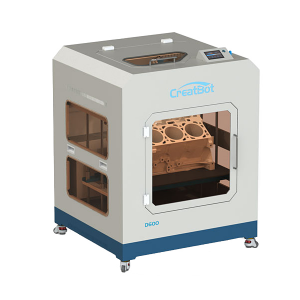

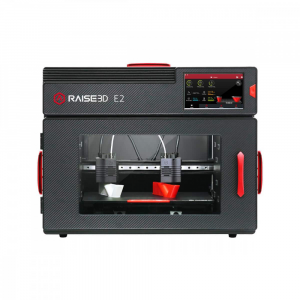

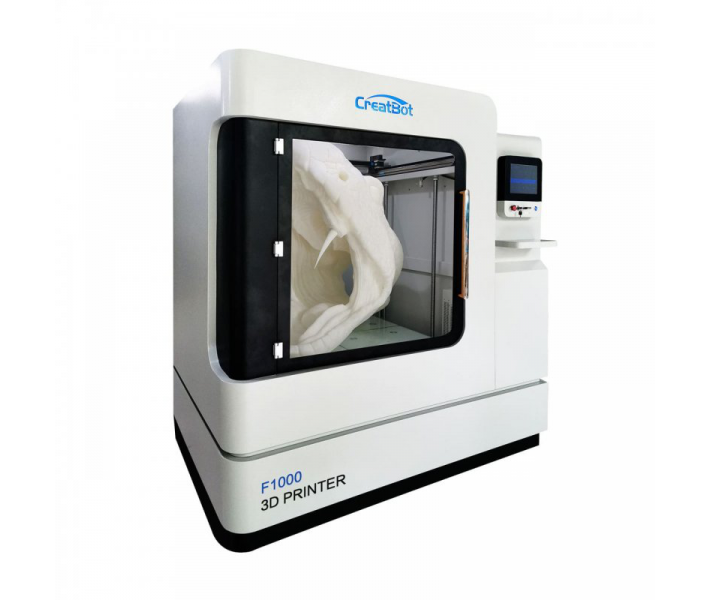

CreatBot F 1000 3D Printer

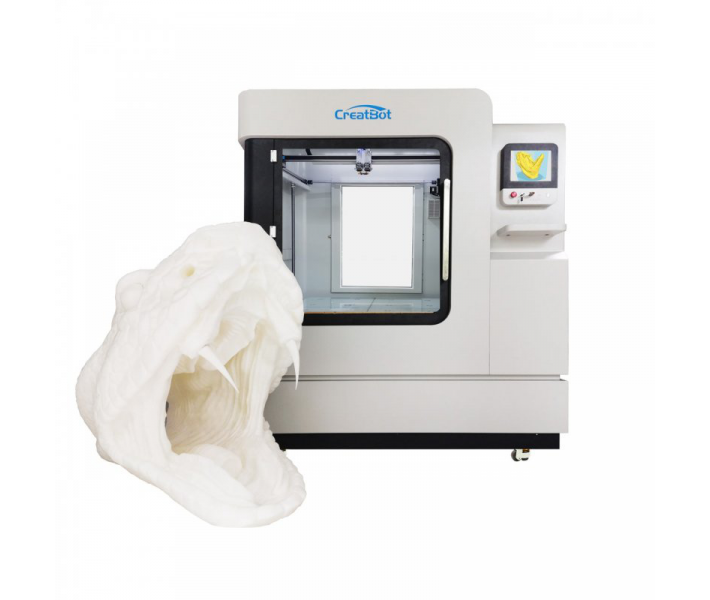

Printing Area — 1000 × 1000 × 1000 mm.

CreatBot F1000 was created to make industrial 3D printing of large objects and prototypes as simple as possible. The CreatBot F 1000 3D Printer is an industrial 3D printer that meets market demand and is equipped with a new intelligent dual extruder kit, a closed heated chamber, an automatic calibration system, and camera control for producing large, high-quality parts. The camera control technology allows customers to monitor the 3D printing process using an application, which can ensure the best print quality in the shortest time without failures. Thanks to the fast-heating platform and hot chamber, this "workhorse" with a large build volume delivers incredible results when using high-quality materials.

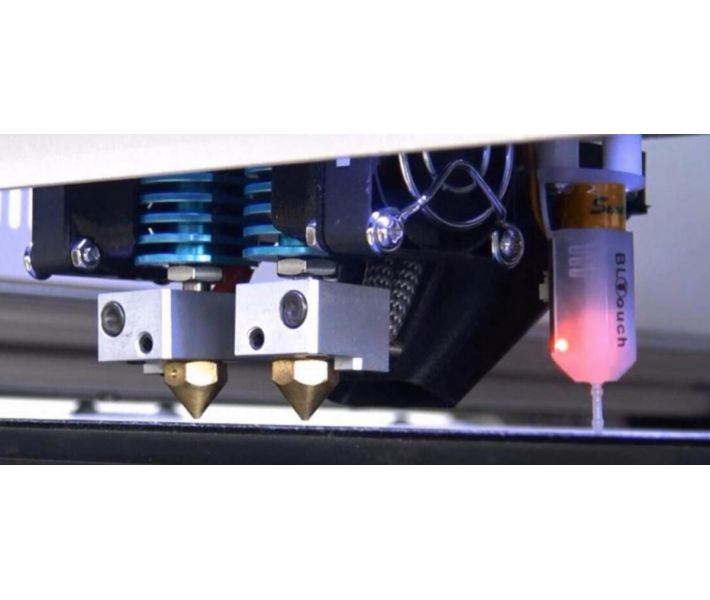

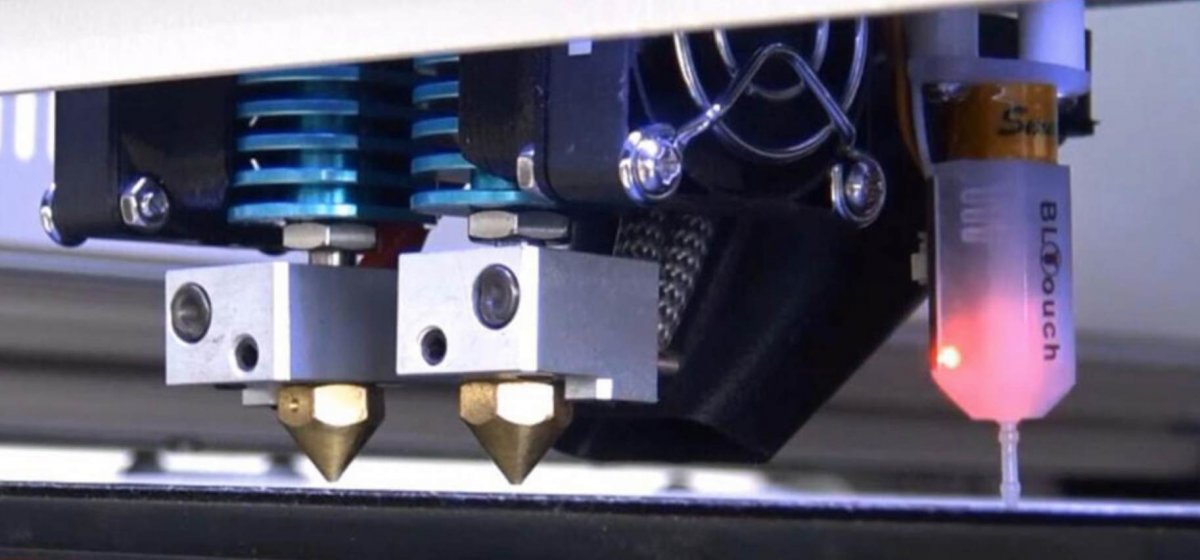

Smart Dual Extruders 420 °С

The CreatBot F 1000 3D Printer has a built-in new intelligent dual extruder kit with a high temperature of up to 420 °C. It is capable of printing not only very large prototype parts from PLA at maximum speed but also high-quality functional parts from absolutely all types of plastics existing in 3D printing today: PLA, ABS, PLA+, ABS+, ASA, HPLA, Elastan, Plastan, Primalloy, Flex, TPU, TPE, PMMA, PET, POM, PEEK, PA (Nylon), PA6, Conductive ABS, Flame Retardant, Marble White PLA, Ceramic, Aluminum, Cooper, Bronze, Brass and Gold PLA filaments, Wood, Carbon Fiber, PC, PETG, HIPS, PP, PVA, and others. The Dual-Hotend is easy to maintain and available for replacement.

CreatBot F 1000 3D Printer Stability

The CreatBot F 1000's one-piece steel body not only ensures stability during printing but also significantly increases its service life. The optimization and interaction of the overall structure ensure stable and efficient operation. The first batch of CreatBot 3D printers with a one-piece steel body worked for 9 years and over 30,000 hours.

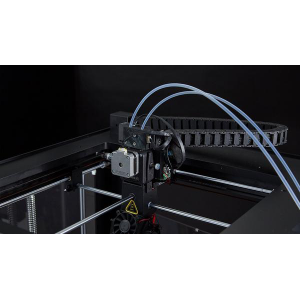

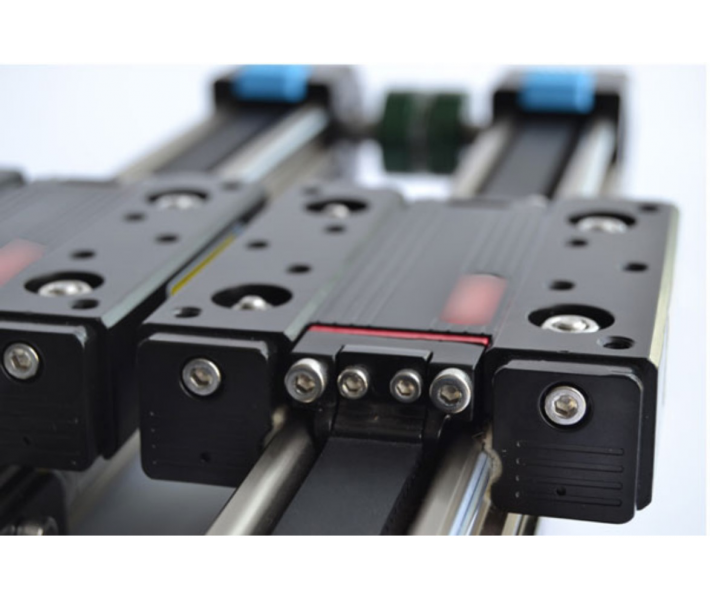

High-Precision Rail Guide CreatBot F 1000

The high-precision rail guide allows for printing models with high accuracy, 4~5 times higher than other 3D printers with optical axes on the global market. This structure ensures precise filament feeding, allowing for fast and error-free printing of large models.

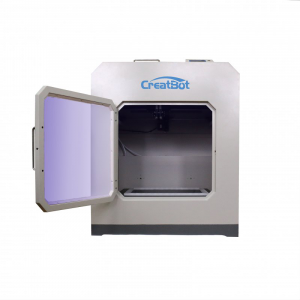

Fully Enclosed Chamber. Chamber and Filament Drying

The fully enclosed chamber can block all external interferences (temperature fluctuations, etc.). Additionally, this design can reduce noise while maintaining a constant temperature so that the model does not deform. The heated chamber, up to 60 degrees, ensures high-quality printing for complex materials such as: ABS, PC, PC-Carbon, PEEK, etc. The filament drying chamber provides a temperature of 45 and 65 °C for drying nylon, PC, ABS, PLA, and other materials with high water absorption.

Filament Run-Out Detector. Print Resume Function

The CreatBot F 1000 3D Printer will automatically remember the current position and save the print data. It will continue printing from the last stopped point after the power is turned on.

The printer has a filament monitoring sensor. If the filament runs out, the CreatBot F 1000 will stop incorrect printing and notify you. After this, you can resume 3D printing from the point of stop.

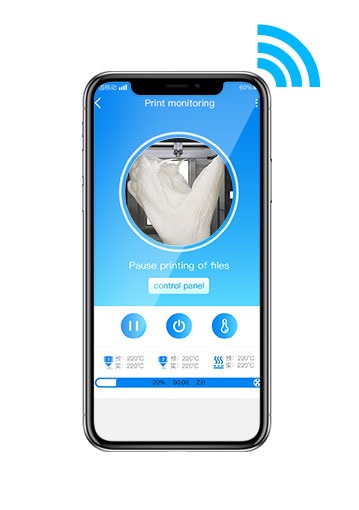

Print Control with Video Camera

The video camera control technology allows clients to remotely monitor the 3D printing process for speed, pause, temperature, etc., using an application, which allows achieving the best print quality in the shortest time without failures. This is a very useful function for large models and long print jobs.

Automatic Platform Calibration

Using 25 points with the BL-Touch sensor to maintain the platform's flatness level at the initial stage, with an intelligent Z-axis compensation table during the printing process to achieve fully automatic platform leveling.

Technical Specifications CreatBot F 1000

| Printing | |

| Printing Technology | Fused Deposition Modeling |

| Build Volume | 1000×1000×1000 mm |

| Number of Extruders | Two |

| Accuracy | 0.1 mm |

| Layer Height | 0.05 mm |

| Filament Diameter | 1.75 mm |

| Material Types | PLA, ABS, PLA+, ABS+, ASA, HPLA, Elastan, Plastan, Primalloy, Flex, TPU, TPE, PMMA, PET, POM, PEEK, PA (Nylon), PA6, Conductive ABS, Flame Retardant, Marble White PLA, Ceramic, Aluminium, Cooper, Bronze, Brass and Gold PLA filaments, Wood, Carbon Fiber, PC, PETG, HIPS, PP, PVA, and others. Absolutely all types of plastics existing in FDM 3D printing |

| Nozzle Diameter | 1.0 mm(0.4~1.5 mm) |

| File Type | STL, OBJ, AMF, Gcode |

| Temperature | |

| Max. Nozzle Temperature | 420 °С |

| Max. Bed Temperature | 100 °С |

| Chamber Heating Temperature | 60 °С |

| Filament Drying Chamber Temperature | 45 °С / 65 °С |

| Mechanics | |

| Construction | Power-Coated Steel, Aluminum Casting for Motion Components, POM |

| Platform | Glass Ceramic Panel |

| Platform Calibration | Automatic |

| Extruder | Smart Dual Extruders |

| Stepper Motor | 1.8° Step Angle with 1/16 Micro-stepping |

| X Y Positioning Accuracy | 0.011 mm |

| Z Positioning Accuracy | 0.002 5 mm |

| Software | |

| Software Bundle | CreatWare, Simplify 3D, Cura, Slice 3r, etc |

| File Types | STL,OBJ,Gcode,AMF |

| Operating System | Win7/8/10, MacOS |

| Special Features | |

| Power Outage Recovery | Saves the date when the printer shut down |

| Filament Sensor | The printer pauses if it detects a broken filament |

| Automatic Shutdown | Automatic shutdown of the printer after printing stops. |

| Video Camera Control | Remote control of the 3D printing process using a built-in video camera in real-time |

| Speed | |

| Best Printing speed | 60 mm/s |

| Max. Printing speed | 120 mm/s |

| Electronics | |

| Power Requirements | 220~240 V, 50~60 Hz |

| Screen | 9.7-inch full color touch screen independent operating system (multi-language) |

| Maximum Power | 4 000 W |

| Storage Media | U Disk |

| Connectivity | USB |

| Dimensions | |

| Printer Size and Weight | 1740×1300×1920 mm 550 kg |

| Printer Size and Weight in Packaging | 1910×1510×2205 mm 640 kg |