- Stock: In Stock

- Product code: 00-00011597

- Shipping Weight: 750.00kg

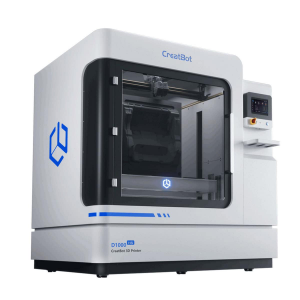

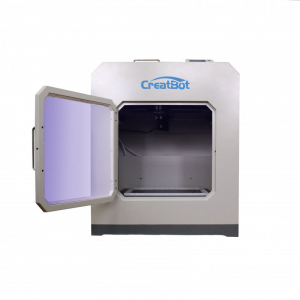

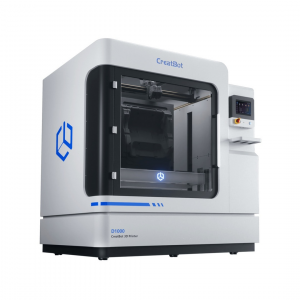

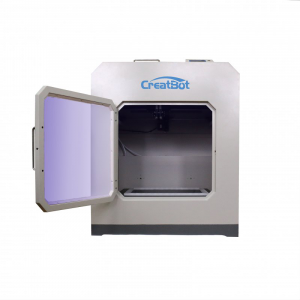

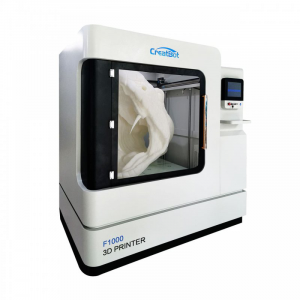

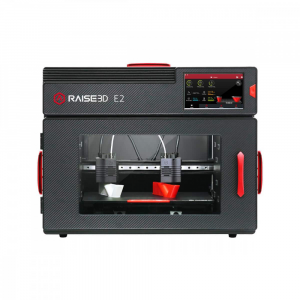

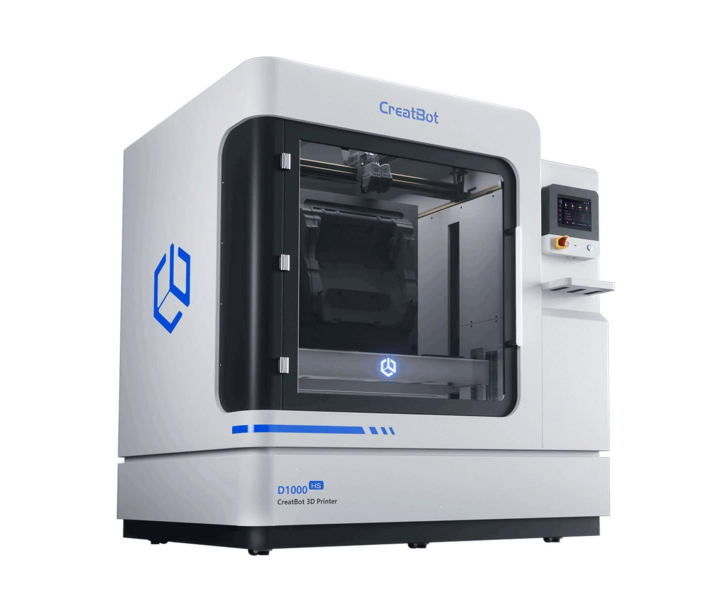

Large industrial 3D printer CreatBot D1000 HS

The CreatBot D1000 HS is a fast industrial 3D printer based on the CreatBot D1000 for the realization of ambitious projects.

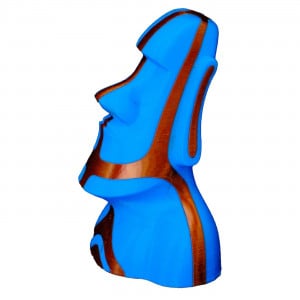

The CreatBot D1000 HS is a game changer in the world of large format 3D printing. Designed for ambitious projects, this industrial-strength machine offers a massive 1000x1000x1000mm build volume, making it ideal for creating custom 3D printed parts and prototypes. With lightning-fast print speeds of up to 300 mm/s and dual extruders, you can bring your projects to life quickly.

The new version of the high-speed printing machine, based on in-depth development by Klipper, uses a new hot tip with a flow rate of up to a record 90 mm³/s.

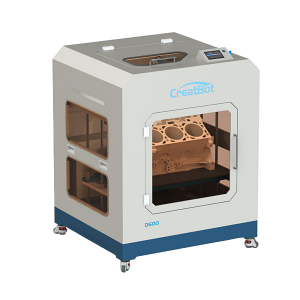

It is the ideal machine for creating large and full-size parts, prototypes, tools, molds, jigs and fixtures in the enterprise. You can have a fully functional, high-quality prototype within days. Use large PLA, ABS, ASA, PA-CF filaments that are well suited for your large models without worrying about frequent filament changes.

Fast printing of large models from engineering materials

- Large build volume of 1000*1000*1000 mm – create massive parts and models with ease.

- High-speed printing up to 300 mm/s – reduce production time for large parts and increase efficiency.

- Dual extruders – print with multiple materials at the same time.

- High temperature materials. The maximum nozzle temperature of 420 °C allows you to work with a wide range of technical materials.

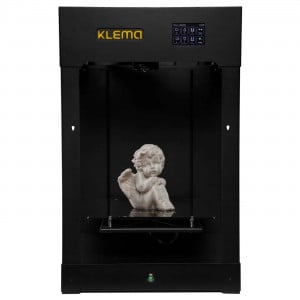

- High print resolution of up to 0.05 mm.

- Reliable and durable. The robust design is built to last.

- Advanced camera control technology. User-friendly: easy to set up and operate.

- Reliable printing 24/7.

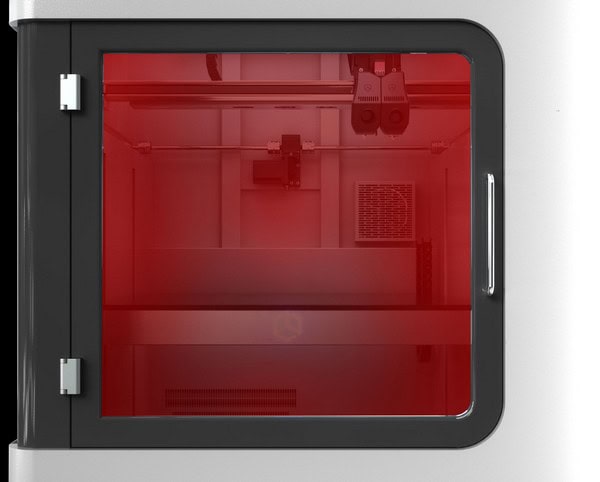

- Fully enclosed print chamber.

Application of the CreatBot D1000 HS

The CreatBot D1000 HS was designed to make industrial 3D printing of large-scale objects and prototypes as easy as possible:

- Design prototypes

- Functional prototypes

- End-use parts

- Spare parts

- Molds and molds

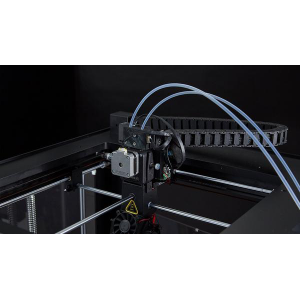

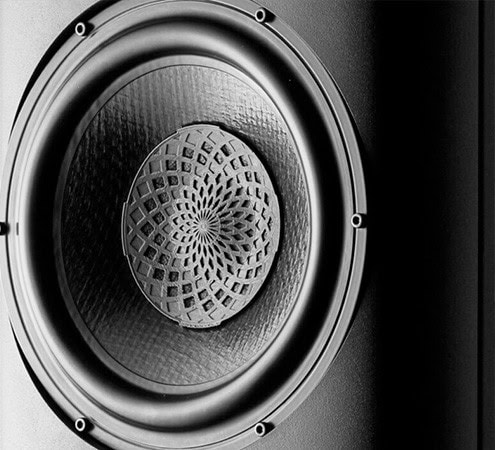

Twin extruders with automatic lift-off 420 °C

The D1000 HS is equipped with a new intelligent auto-lift dual extruder set with a hot end temperature of up to 420 °C, it uses a new hotend with a flow rate of up to a record 90 mm³/s. The hotend can be quickly changed to another size. it is capable of printing not only huge prototypes in ABS, ASA at the highest speed, but also PET-CF, UltraPA-CF and other high quality materials with quick release auxiliary materials for direct application. The dual-hotend is easy to maintain and available for replacement.

Important features for great print results

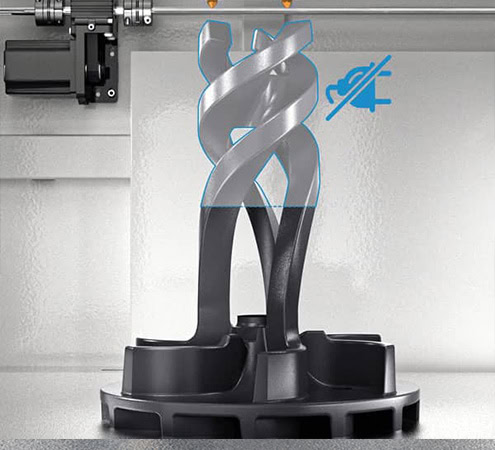

Resume printing after a power failure and detect the presence of filament

The printer automatically remembers the current position and saves the print data, lowers the platen, and pulls the ribbon when the power is suddenly turned off. It will continue to print from the last time it stopped after being turned on. No traces.

The printer will avoid printing incorrectly by stopping printing and warning you when the ribbon is low.

Linear rails and servo motors

When the length reaches 1000 mm+, the small rail has a large deflection. The D1000 precision linear rail is very thick and strong. It will not deform or lose accuracy after the millionth stroke of the print head.

With servo motors, with timeliness, fast response, no inertia and no delay. Closed-loop position control overcomes the problem of pitch loss. Heat and noise are greatly reduced. This gives the print model ultra-high performance at high speeds.

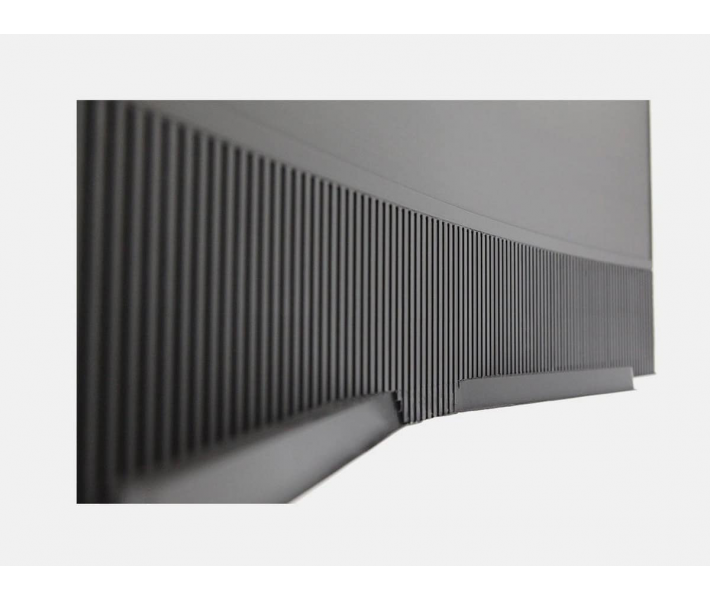

Hot chamber and dry filament compartment

The 70 °C hot platen ensures print quality on high-quality materials. The fully enclosed chamber can block all external interference. This frame also reduces noise by providing a constant temperature, ensuring that the model does not warp.

The filament drying room provides a 70 °C chamber temperature for drying filaments weighing 2*5 kg/roll, such as PLA, nylon, PC, ABS and other water-absorbing materials.

Automatic platform leveling

Using 100 points through a high-precision servo encoder to save the initial flatness level data of the platform through the intelligent Z-axis height of the compensation table during the printing process to achieve fully automatic leveling.

HEPA air filter

The air filter system can adsorb impurities and gases generated during the printing process of special filament such as ABS, nylon, PC, safer and more environmentally friendly, which is more suitable for homes, schools, office space.

Remote process control using a video camera

The air filter system can adsorb impurities and gases generated during the printing process of specialty filament, such as ABS, nylon, PC, more safe and environmentally friendly, which is more suitable for homes, schools, office environments.

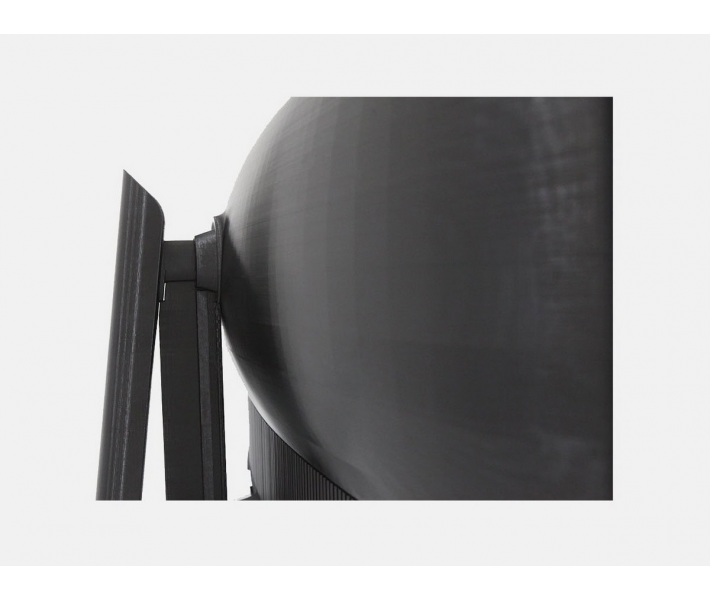

Stable body

This fast industrial 3D printer in all-steel body not only ensures stability during printing, but also significantly extends the service life. The optimization and interaction of the overall structure ensure stable and efficient operation. The first batch of CreatBot 3D printers with an all-steel body has been in operation for 9 years and over 30,000 hours.

Fast industrial 3D printer at an affordable price

The CreatBot D1000 HS was created to make industrial 3D printing of large-scale objects and prototypes as easy as possible. It is an industrial 3D printer that meets market demands and features a new intelligent dual extruder kit, heated enclosed chamber, automatic alignment and chamber control system for large, impressive prints. The camera control technology allows customers to control the printing process through an APP, which can produce the best print quality in the shortest time without disruption. With a fast-heating platform and hot chamber, this high-resolution, large-font workhorse delivers incredible results using high-quality materials. The CreatBot D1000 sets a new standard in additive manufacturing and expands the material capabilities of large-scale 3D printers, enabling more companies to significantly reduce costs and time.

Undoubtedly, the CreatBot D1000 HS is your best choice if you are looking for an industrial large-scale 3D printer for prototypes and engineering-grade materials.

Specifications

| Printing technology | FDM |

| Single extrusion assembly volume | 1000*1000*1000 mm |

| Double extrusion | 940*1000*1000 mm |

| Nozzle count | 2 |

| Layer resolution | 0,05 mm |

| Filament diameter | 1.75 mm |

| Filament compatibility | PLA, ABS, ASA, PETG, PC, Nylon, ABS-CF, PC-CF, PET-CF, PET-GF, UltraPA-CF, etc. |

| Nozzle diameter | 0.8 mm (0.3-1.0 mm optional) |

| Type of print file | STL, OBJ, AMF, Gcode |

| Max. Nozzle temperature | 420 °C |

| Max. Ball temperature | 100 °C |

| Hot chamber temperature 60℃ | 60 °C |

| Filament drying temperature | Up to 70 °C |

| Printing speed | 100-300 mm/s |

| Carriage speed | 300 mm/s |

| Flux speed | 90 mm³/s |

| Working surface | Aerospace aluminum plates + removable magnetic platform |

| Alignment | Automatic |

| Extruder | Smart Dual Extruders |

| Extruders with automatic lifting | Yes |

| Positioning accuracy | X Y 0.011 mm; Z 0.0025 mm |

| Software | CreatWare, Orca Slicer, Cura, Simplify3D, Prusa, etc. |

| Supported file types | STL, OBJ, Gcode, AMF, STP, STEP, etc. |

| Operating Systems | Windows, macOS |

| Air filter | HEPA+Carbon |

| Thread detection sensor | Stops printing when you run out of filament |

| Firmware | Klipper – high speed |

| Camera Control | Remote camera monitoring and real-time control of printing process |

| Power Requirements | 220~240V, 50~60Hz |

| Screen | 10-inch full color touch screen, independent operating system (multilingual) |

| Printer power rating | 4000W, camera: 4500W |

| Data carrier | U Disk/WIFI |

| Connection | USB |

| Product size and weight | 1810*1350*1942 mm 650 kg |

| Package size and weight | 1980×1520×2200 mm 750 kg |