- Stock: In Stock

- Product code: 00-00013698

- Shipping Weight: 880.00kg

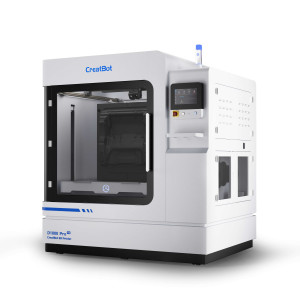

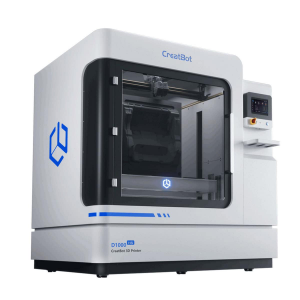

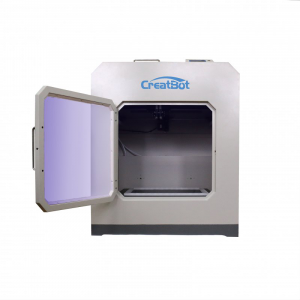

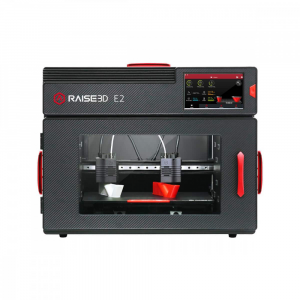

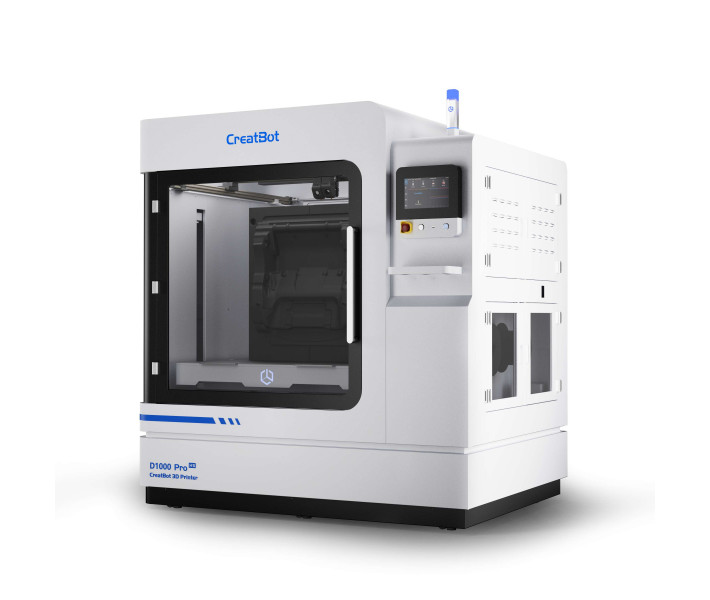

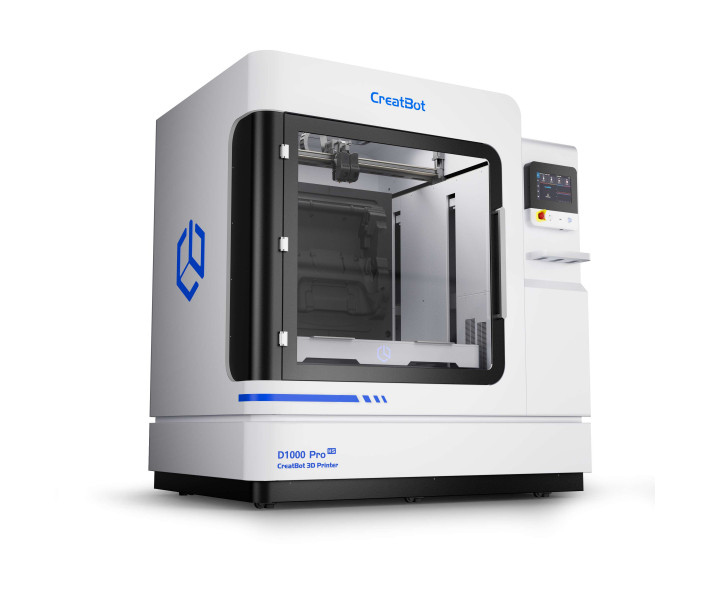

3D printer CreatBot D1000 Pro HS: Industrial Scale and Speed

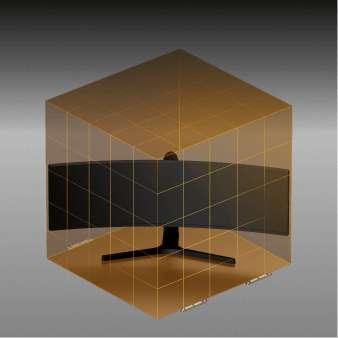

Discover the future of large-scale additive manufacturing with the 3D printer CreatBot D1000 Pro HS. This machine represents the pinnacle of industrial-grade engineering, offering a massive one-cubic-meter build volume designed for creating full-size parts, tools, and molds in-house. Upgraded significantly from its predecessor, the D1000 model, this "High Speed" version utilizes advanced Klipper firmware and a powerful new hotend to achieve record-breaking flow rates. Whether you need functional prototypes or end-use fixtures, this printer delivers exceptional quality and efficiency, making it the ultimate asset for professional production environments.

What is new on the D1000 Pro HS?

Unmatched Printing Speed

The 3D printer CreatBot D1000 Pro HS has been meticulously engineered for rapid production without compromising quality. It features a new generation hotend capable of a flow rate up to 90 mm³/s, allowing for stable printing speeds of 300 mm/s—five times faster than the standard model. Alongside speed, it introduces a dual nozzle shutter for automatic synchronization and a lightweight auto-rising extruder system.

With a massive build volume of over 1050 x 1050 x 1050 mm and precise eddy current bed leveling (0.001 mm accuracy), this machine ensures that every part is manufactured to the highest standard, every single time.

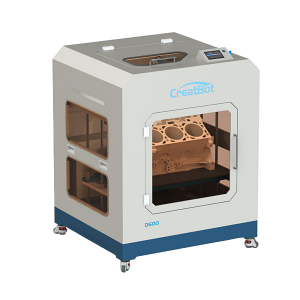

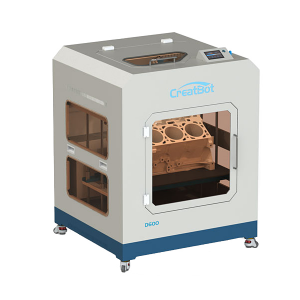

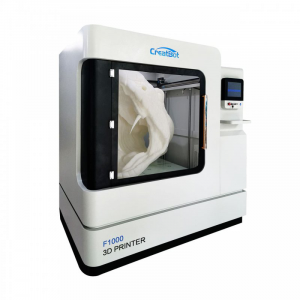

Large-Sized Prototype Manufacturing

Proven Automotive Applications

Major global suppliers like Faurecia utilize the 3D printer CreatBot D1000 Pro HS for high-level automotive engineering tasks. By using this advanced machinery, they design and develop intricate seat molds for leading brands such as Audi, VW, and Nissan. The printer's ability to handle Nylon-carbon fiber materials allows for the creation of bowls and lids that withstand pressures up to 100 MPa. With 50% infill, these prints demonstrate excellent performance, passing strict industrial testing and proving the machine's capability in demanding real-world scenarios.

Size worry-free For High strength prototype

Advanced Material Capabilities

Designed to simplify the industrial 3D printing of large-scale objects, the 3D printer CreatBot D1000 Pro HS is the ideal choice for engineering-grade applications. If you are seeking an alternative to the fragility of PLA or the warping issues of ABS, this machine pairs perfectly with revolutionary materials like UltraPA-CF. Using a large-size nozzle, you can produce oversized models in just a few days that boast high strength (80 MPa) and temperature resistance up to 150°C. It removes the barriers to creating durable, functional prototypes.

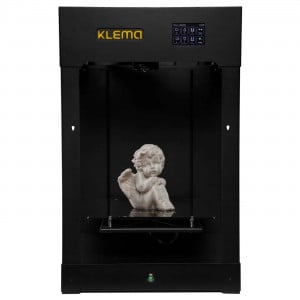

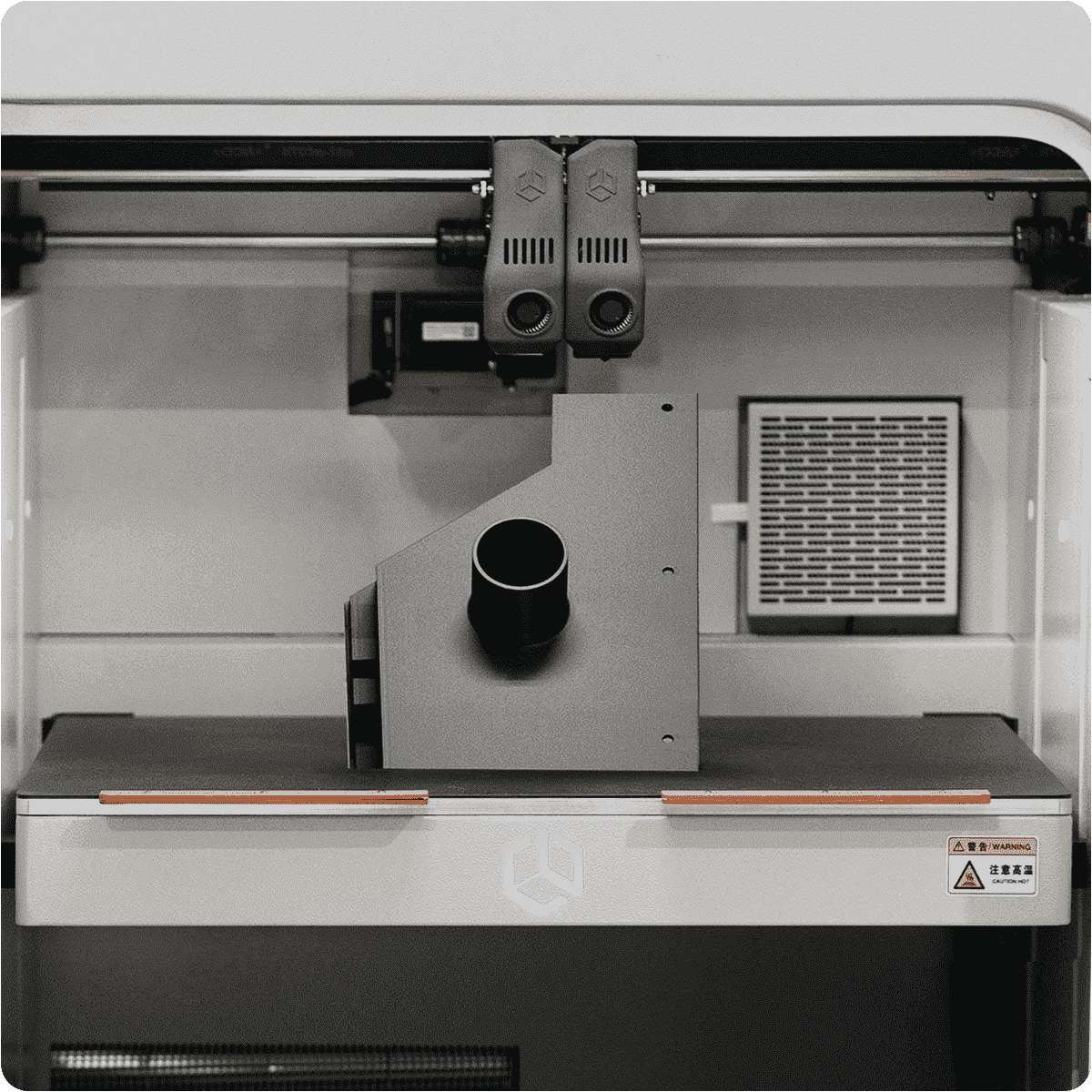

Auto-rising Dual Extruders 420 ℃

Versatile Dual Extrusion

Equipped with a smart auto-rising dual-extruder kit, the D1000 Pro HS reaches temperatures up to 420°C. This allows for the rapid replacement of hotends to suit different sizes and needs. The system excels at printing huge PLA models with water-soluble PVA supports for complex geometries. Furthermore, it easily handles high-performance materials such as ABS, PC, Nylon, and Carbon Fiber for direct applications. The dual-hotend design is not only affordable to replace but also incredibly easy to maintain, ensuring continuous uptime.

Active Heated Chamber Benefits

Superior Layer Bonding

To combat the challenges of printing large engineering materials, this printer features an active heated chamber that reduces thermal stress and warping. By maintaining a controlled environment, it prevents uneven cooling that leads to delamination or cracking in materials like ABS. This heat management enhances molecular diffusion, ensuring stronger interlayer bonding. Additionally, the chamber minimizes the impact of ambient humidity on hygroscopic materials, such as nylon, guaranteeing process consistency and part-to-part uniformity essential for industrial production.

Intelligent Solutions for Chamber Temperature

Counteracting Thermal Deformation

While many manufacturers add heated chambers without considering the structural consequences, CreatBot utilizes over eight years of research to solve thermal deformation issues. As chamber temperatures rise, metal frames can expand, leading to axis misalignment. The 3D printer CreatBot D1000 Pro HS employs an Intelligent Chamber Heating Algorithm combined with Z-Axis Magic Box Technology. These patented features predict irregular deformations and compensate for them in real-time, ensuring flawless prints and maintained surface finish even when slight structural shifts occur.

Outage Restore and Filament Detection

Fail-Safe Printing

Reliability is key for long-duration prints. The machine automatically memorizes the current position and saves print data in the event of a sudden power loss. It lowers the platform and retracts filament, ready to resume exactly where it left off once power is restored, leaving no trace of the interruption. Furthermore, the intelligent filament detection system pauses the printer and alerts the user when material runs out, preventing invalid printing and wasted resources.

Linear Rail and Servo Motors

Robust Mechanical Structure

When printing objects exceeding 1000 mm in length, standard rails can suffer from deflection. The D1000 Pro HS utilizes an extremely thick and strong linear rail structure designed to resist deformation. Coupled with precise servo motors, this robust framework ensures the print head maintains accuracy even after millions of shock movements. This heavy-duty construction is essential for maintaining the high precision required for industrial-grade large-format printing.

Filament Dry Room and Auto Leveling

Optimized Print Environment

To ensure material quality, the printer includes a filament dry room capable of maintaining temperatures between 45°C and 65°C. This feature dries 2x5kg rolls of filament, such as Nylon, PC, or ABS, preventing water absorption defects.

Additionally, the auto-leveling platform uses a high-precision servo probe to sample 100 points on the bed. Through intelligent Z-axis compensation, the system adjusts platform height automatically during the printing process to guarantee a perfectly flat first layer.

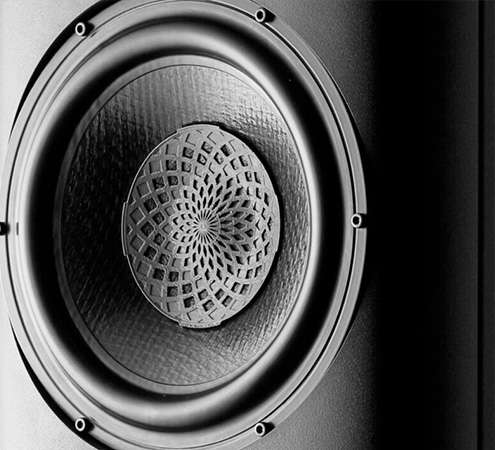

Safety and Control: HEPA and Camera

Remote Monitoring Systems

Safety and convenience are integrated into the design with a HEPA air filter system that adsorbs impurities and gases generated when printing specialized filaments like ABS. This makes the unit suitable for offices, schools, and homes.

For operational control, the Camera Control Technology allows users to remotely monitor the printing process via an APP. You can adjust speed, pause prints, and check temperatures remotely, ensuring the best quality in the shortest time without failure.

Stability and Reliability

Built to Last

The whole-steel body of the 3D printer CreatBot D1000 Pro HS ensures immense stability during high-speed operation and significantly extends the machine's working life. The optimized structural cooperation guarantees sustainable and efficient performance. With a legacy of durability, the first batches of CreatBot printers with steel bodies have been in operation for over 13 years, clocking more than 30,000 hours of work, proving their status as affordable and reliable large 3D printers.

Technical Specifications

- Print Technology: FDM/FFF

- Build Volume (Single Extrusion): 1050 x 1050 x 1050 mm

- Build Volume (Dual Extrusion): 990 x 1000 x 1000 mm

- Number of Nozzles: Double

- Auto Rising Extruders: Yes

- Layer Resolution: 0.05 mm

- Filament Diameter: 1.75 mm

- Filament Compatibility: PLA, ABS, ASA, PP, PETG, PC, Nylon, TPU, ABS-CF, PC-CF, PET-CF, PET-GF, UltraPA-CF, PPS-CF, etc.

- Nozzle Diameter: 0.8 mm (0.3-1.0 mm optional)

- Print File Type: Gcode

Temperature

- Max. Nozzle Temperature: 420°C

- Max. Bed Temperature: 100°C

- Hot Chamber Temperature: 80°C

- Filament Dry Room Temperature: 0°C / 70°C

Speed

- Max Print Speed: 300 mm/s

- Flow Rate: 90 mm³/s

Electrical

- Power Requirements: 220~240 V, 50~60 Hz

- Screen: 10-inch full color touch screen independent operating system (multi-language)

- Rated Power: Printer: 5500W, Chamber: 6000W

- Storage Media: USB / U disk / WiFi / LAN

Software

- Software: CreatWare, Orca Slicer, Cura, Simplify3D, Prusa, etc.

- Supported File Types: STL, OBJ, Gcode, AMF, STP, STEP

- Operating Systems: Windows ALL / Mac OS

Special Functions

- Air Filter: HEPA + Carbon

- Filament Detection: Pause printing when filament run out

- Firmware: Klipper - High speed

- Camera Control: Camera remote monitoring and real-time control of the printing process

- Dual Nozzle Auto-Resume Printing: Auto-switch to backup nozzle on filament runout

- Bed Leveling Tech: Eddy current induction

- XY Offset Tech: HD macro camera

- Z Offset Tech: Dual photoelectric switch

- Nozzle Shutter Tech: Automatic Nozzle Shutter for auto-lifting extruders

- Door Opening Detection: Yes

- Chamber Insulation: Double-layer insulation cotton

Mechanical

- Build Plate: Aviation aluminum plates + removable magnetic platform

- Build Plate Leveling: Automatic

- Extruder: Smart dual extruders

- Auto Raising Extruders: Yes

- X Y Positioning Precision: 0.011 mm

- Z Positioning Precision: 0.0025 mm

Size & Weight

- Product Dimensions & Weight: 1850 x 1350 x 1942 mm; 750 kg

- Packing Size & Weight: 2070 x 1610 x 2240 mm; 880 kg

Order the CreatBot D1000 Pro HS from 3DDevice

Trust the professionals at 3DDevice for your industrial manufacturing needs. We have been experts in the additive manufacturing market since 2012, providing tailored advice and assistance in choosing the right equipment. We provide qualified support before, during, and after your purchase. As an official representative of CreatBot in the region, we guarantee the best price, official warranty, and certified service support for the 3D printer CreatBot D1000 Pro HS.