- Stock: In Stock

- Product code: 00-08800007

- Shipping Weight: 400.00kg

- SKU: F-SR-0001, S-DF-A3277

Available Options

Markforged Sinter-1

The Markforged Sinter-1 is a high-performance and reliable furnace for high-quality sintering of washed 3D printed metal parts.

The furnace has a large working volume of 4760 cm3, so it effortlessly transforms brown (washed) parts into an almost completely dense metal mold at temperatures of up to 1300 °C. Thanks to 30 years of injection molding (MIM) technology, it is ideal for sintering medium and small batches of parts. Multiple components can be sintered at the same time!

The sintering oven can be controlled via USB, network connection or WLAN. The sintering data is also determined by the Eiger software.

A gas system is required to operate the sintering oven.

- Dimensions: 1067*505*720 mm

- Sintering capacity: cylindrical 141 mm inner * 305 mm long

- Sintering volume: 4760 cm3

Compatible with Markforged FX10 3D printer.

Buy Markforged Sinter-1

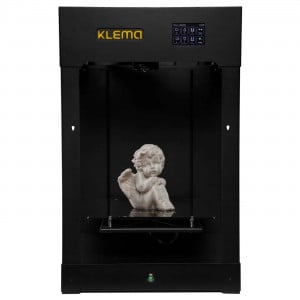

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.