- Stock: In Stock

- Product code: 00-00000227

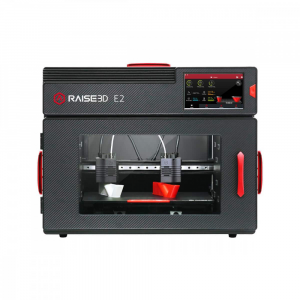

Raise3D Hyper Speed Upgrade Kit buy in Ukraine for Pro3

On this page you can buy Hyper Speed Upgrade Kit – a set of hardware, software and filament extensions for your Raise3D Pro3 and Pro3 Plus 3D printer for super-fast, high-quality 3D printing.

By installing this kit and printing with the specially designed Hyper Speed filament line, you will increase your print speed from an average of 50 – 80 mm/s to 200 – 350 mm/s without sacrificing print accuracy or part quality.

The printer with the new Hyper Speed FFF feature can print with 600 – 1000 grams of filament within 24 hours, meaning that any part weighing less than 400 grams will be ready within 12 hours.

The Hyper FFF 3D printing upgrade kit contains*:

- Upgrade Letter – Software upgrade letter with a code to download the necessary files to upgrade the Pro3 series.

- Two 0.4 mm high-speed hot ends (Pro3 Series only).

- Hyper Speed Automatic Calibrator (Pro3 Series only).

- Hyper Speed PLA White filament spool, 1 kg / 1.75 mm.

- Hyper Speed ABS Natural filament spool, 1 kg / 1.75 mm.

* Please note that for Hyper Speed to work properly on a Pro3 Series printer activated with Hyper, you must install Hyper Speed Hot Ends 0.4 mm (Pro3 Series only), Hyper Speed Auto Calibrator (Pro3 Series only), and Hyper Speed filament. Failure to install any of these components may result in print failure.

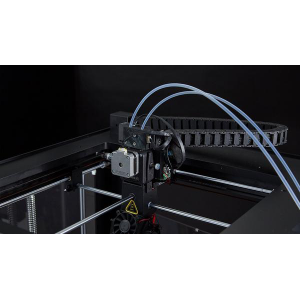

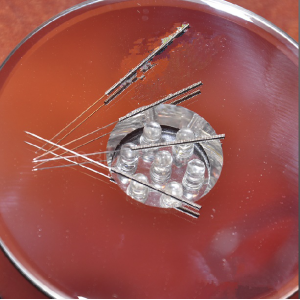

Hyper-speed hot end 0.4 mm

High-speed printheads designed for hyper-speed 3D printing on Pro3 Series printers.

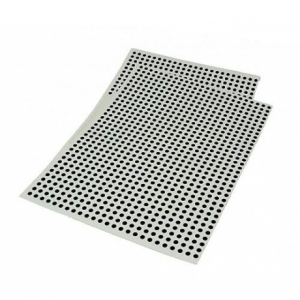

Hyper-speed Automatic Calibrator

With this automatic frequency calibrator, the Pro3 Series printer can measure its own frequency and adjust the settings independently. Thanks to the rugged and stable design of the Pro3 Series, the printer can maintain its own frequency for months without change. It is recommended to perform a calibration process every 2-3 months. A manual calibration process is also included.

Hyper Speed ABS and PLA high-speed filaments

The Hyper Speed filament line includes the most commonly used ABS and PLA filaments. This materials have been specially processed and optimized for FFF hyper-speed printing.

When printing at high speed, the filament is quickly fed into the thermal unit and the polymer has very little time to melt to a liquid state, which can cause nozzle clogging and poor bonding between layers. In addition, during high-speed printing without a heated chamber, ABS is prone to deformation and delamination of the printed part.

Game-changing Hyper FFF technology

Hyper FFF™ is a system designed for efficiency and productivity that will increase FFF printing productivity without sacrificing printed part quality.

100% quality, 300%+ productivity.

- Active vibration reduction algorithm

At the heart of Hyper FFF™ technology is an active vibration suppression algorithm. This algorithm calculates an optimized acceleration pattern and absorbs excessive amounts of vibration whenever the print head makes any high-speed change of direction.

The processor measuring the extruder head’s natural frequency and divide one acceleration command into two equivalent accelerations. It create two return vibration waves, which in turn cancel their own vibration during the return phase, so the printer head manages to minimize its own friction and jitter with the same equipment.

- Equipment

High-speed 3D printing also requires excellent quality hardware to produce high-quality print results.

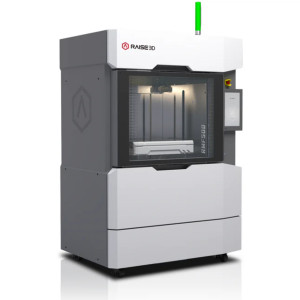

To enable extremely high print speeds, the Pro3 Series has a strong and stable frame that can withstand the effects of extremely high acceleration and high speeds. This ensures high dimensional accuracy and excellent surface quality. In addition, the advanced on-board processors can process over six hundred thousand steps per second and implement an active vibration suppression algorithm on the Pro3 Series 3D printers.

- Filaments

Specially designed materials for high-speed 3D printing – Hyper Speed filaments – to withstand high speeds while maintaining high quality. They have higher fluidity and lower heat capacity. Melting and cooling are faster.

- Software

Raise3D is committed to keeping the slicer software up-to-date. Users have access to the latest filament profiles in a timely manner and maximize the potential of Raise3D printers. The software capabilities developed by Raise3D are an essential component of the Hyper FFF™ to achieve the goal of high-speed printing.

Specifications

| Printing technology | FFF |

| Plastic diameter (mm) | 1,75 |

| Maximum Nozzle Temperature (°C) | 300 |

| Number of Extruders | 2 |

| Type of Feed Mechanism | Direct |

| Nozzle diameter (mm) | 0,4 |

| Print speed (mm/s) | 200 – 350 |

| Supported Materials | Hyper Speed PLA, Hyper Speed ABS |

| Compatibility with the printer | Pro3, Pro3 Plus |

| Software | ideaMaker |

| Producing country | USA |

| Warranty period (months) | 12 |