- Stock: In Stock

- Product code: 00-00012964

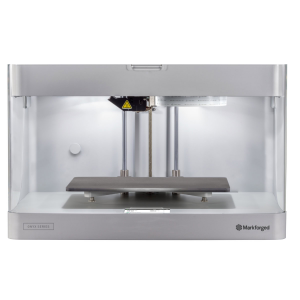

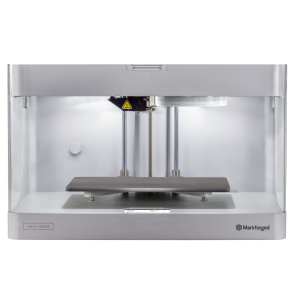

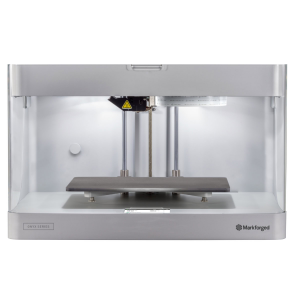

Industrial 3D printer Markforged X5

Industrial 3D printer Markforged X5 can print three-dimensional parts. The printing area of the device is 330*270*200 mm. This is enough to print large parts and prototypes from plastic with the addition of fiberglass. Thanks to the improved extruder, printing with fiberglass can be carried out continuously. All components of the 3D printer are designed to withstand such loads.

High-quality plastic and fiberglass to create durable masterpieces

3D printing on the X5 requires high-quality materials. These are Onyx, Onyx FR, Onyx ESD plastics and fiberglass composite, which is necessary to give the finished product high strength and wear resistance. Composite printing is distinguished by the fact that beautiful products have industrial strength and can withstand significant loads.

Settings monitoring while printing

Unique precision sensors monitor the presence of filament in the extruder and automatically level the table. The X5 sensor unit is an innovative solution for optimizing printing throughout the entire cycle. A powerful and reliable printer can work 24 hours a day and not get tired, printing equally high-quality and accurate products.

Large print volume in Markforged X5

The size of the print table in the 3D printer allows you to print products for car services, work equipment, functional prototypes. Unlike traditional production methods, 3D printing allows you to produce small batches of high-precision parts without unnecessary costs. A reliable and powerful 3D printer will be an excellent assistant in your business.

High quality of finished parts at a low cost

ABS is considered one of the most durable materials for printing. But Onyx plastic, reinforced with fiberglass, is 20 times stronger than it. The rigidity indicators are 10 times higher. The cost of a part printed on Markforged X5 is 20 times lower than the cost of its aluminum counterpart. One of the 2 nozzles in the printer can continuously print with fiberglass. This means that durable parts can be produced continuously.

Convenience and ease of control of Markforged X5

The high-sensitivity touch screen allows you to comfortably control the printer, monitor the wireless connection, and start the printing process.

Eiger – reliable software

The software works stably, allowing you to control the operation of the 3D printer as simply as possible. But the developers do not stop, so Eiger is constantly updated. The advantage of cloud software is that it is constantly updated, so you will always have the latest, best version. The software allows you to manage STL files, catalog them. The printer has the following connections: LAN, USB and W-LAN.

Eiger allows you to design a part for printing in great detail, for example, changing the density of layers in specific areas. This allows you to create models strictly according to requests, save materials and labor costs.

Markforged X5 Industrial Format 3D Printer Kit

- X5 3D Printer

- Plastic Drying Box

- Onyx FFF Filament 800 cm³ Roll × 1

- CFF Fiberglass Filament 50 cm³ Roll × 1

- FF Replacement Nozzles × 3

- Tool Kit

- True Bed X-Series Assembly Platform

Specifications

| Build Field (mm) | 330*270*200 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 50 – 200 |

| Extruder Construction Type | Second generation extruder, detection of plastic absence |

| Leveling System | Kinematic connection of the printing platform – flat with an accuracy of up to 80 µm Laser leveling of the platform, active calibration of the print |

| Maximum Chamber Temperature (°C) | 60 |

| Automatic Filament Switching | Yes |

| Platform Material | Precision ground print platform |

| Internal Part Geometry | Closed Cell or Solid Infill |

| Supported Materials | Onyx, Onyx FR, Onyx ESD, Fiberglass |

| Features | Precision design Continuous fiber reinforcement (CFR) Filling: solid or closed cells |

| Software | Eiger Cloud |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 100–240 VAC, 150 W (2 A peak) |

| Manufacturer Country | USA |

| Weight Netto (kg) | 48 |

| Dimensions Netto (mm) | 584*483*914 |

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.