- Stock: In Stock

- Product code: 00-08800012

- Shipping Weight: 635.00kg

- SKU: F-PR-5002

Available Options

Markforged Metal X set with Wash-1 and Sinter-2

A set that includes a Markforged Metal X metal 3D printer, Wash-1 sink, and Sinter-2 furnace at a more affordable price than if you buy the equipment separately. Thus, you have access to the full technological cycle of metal parts production directly at your production facility, without outsourcing the washing and annealing processes. Production of metal parts with unique shapes in 28 hours!

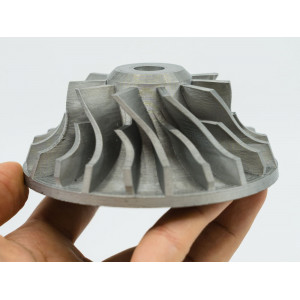

The Metal X metal printing system is based on fourth-generation composite 3D printing technology and is a completely new type of 3D printer. By printing metal powder bonded in a plastic matrix, Markforged has eliminated the safety risks associated with traditional metal 3D printing while enabling new features such as closed cell filling for lighter weight parts and lower costs.

How does the Metal X metal 3D printing system work?

This procedure saves time from design to printing of heavy metal parts.

Design. Once you’ve uploaded your CAD STL file and selected your material, EIGER software does the rest, making it easy to print the part you want.

Printing. The system prints your part with metal powder bonded to plastic, layer by layer to form the shape of your dense metal part. The parts are oversized to compensate for shrinkage during the sintering process.

Sintering. The printed parts go through a washing stage to remove some of the binder. They are then sintered in a furnace and the metal powder is fused into a solid m

Wide range of metal materials

The Metal X printer works with more than five different metal materials. From stainless steel and copper to the high-temperature alloy Inconel 625, you’ll get high-quality metal parts the next day.

Eliminate supply chain headaches

Supply chains can be unpredictable, but they don’t have to put your production needs on hold. Reduce costs and headaches by bringing metal part production in-house with the best metal 3D printer on the market. You don’t have to wait weeks or months for that vital part – you can have it the next day.

Metal X metal printing system

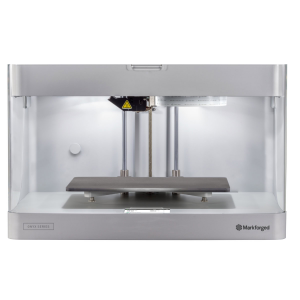

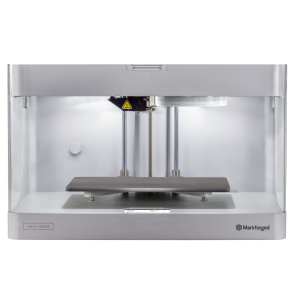

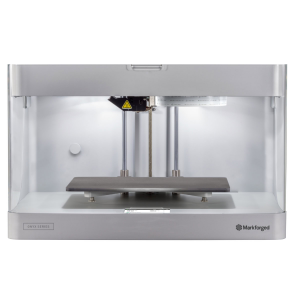

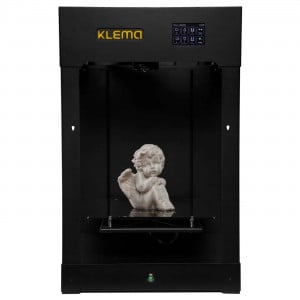

Metal X printer

The Markforged Metal X is a new metal printer that uses a plastic die to bind metal powder, eliminating the safety risks of traditional metal 3D printers. It is safe for use in a shop environment with minimal equipment upgrades and features a precision gantry, heated chamber, print platform, and advanced extrusion equipment.

Sinter-2

The Markforged Sinter-2 is a tube furnace used to sinter metal parts printed on a 3D printer. The Sinter-2 is more advanced than the Sinter-1 and has a larger working volume, more precise temperature control, and a mechanical door lock.

Typically, the Sinter-1 and Sinter-2 have a working time of 26 to 31 hours. However, the Sinter-2 can process small parts in express mode, allowing you to sinter up to 250 g of parts in a quick 17 hours.

Wash-1

Wash-1 is a solvent-based bonding removal system that uses Opteon SF79. Opteon SF80 or Tergo Metal Cleaning Fluid can be substituted if necessary. Wash-1 operates with simple ventilation and has a clear user experience. The Wash-1 system has been tested and confirmed as a safe system for the shop.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.