- Stock: Price on request

- Product code: 00-00011629

- Shipping Weight: 242.00kg

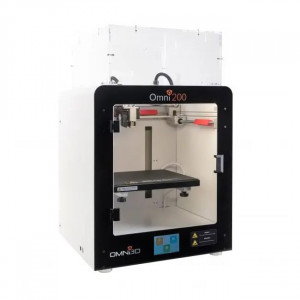

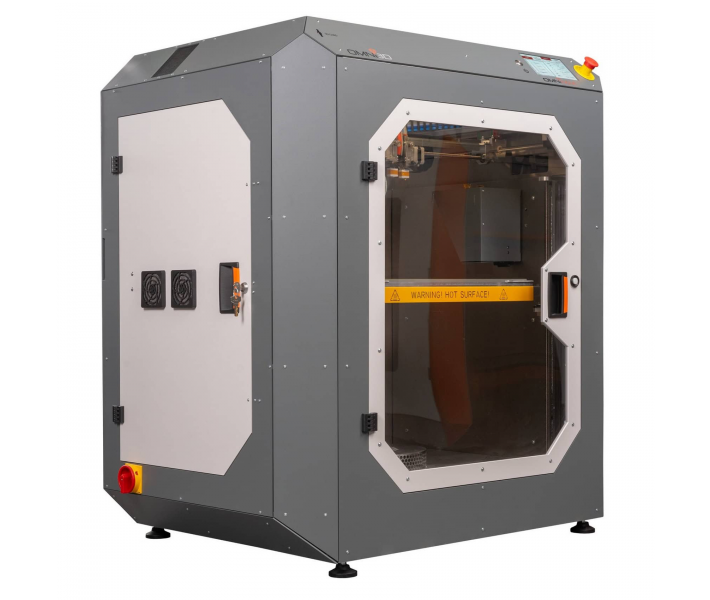

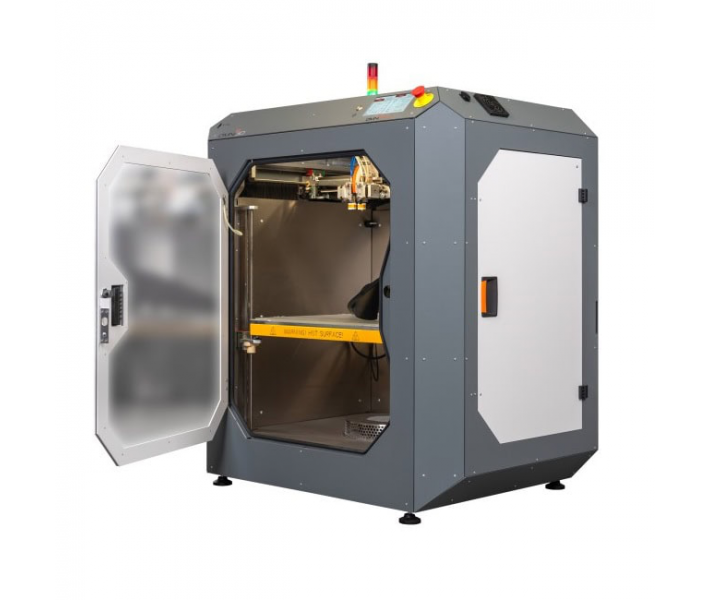

Omni NOVA Industrial 3D Printer

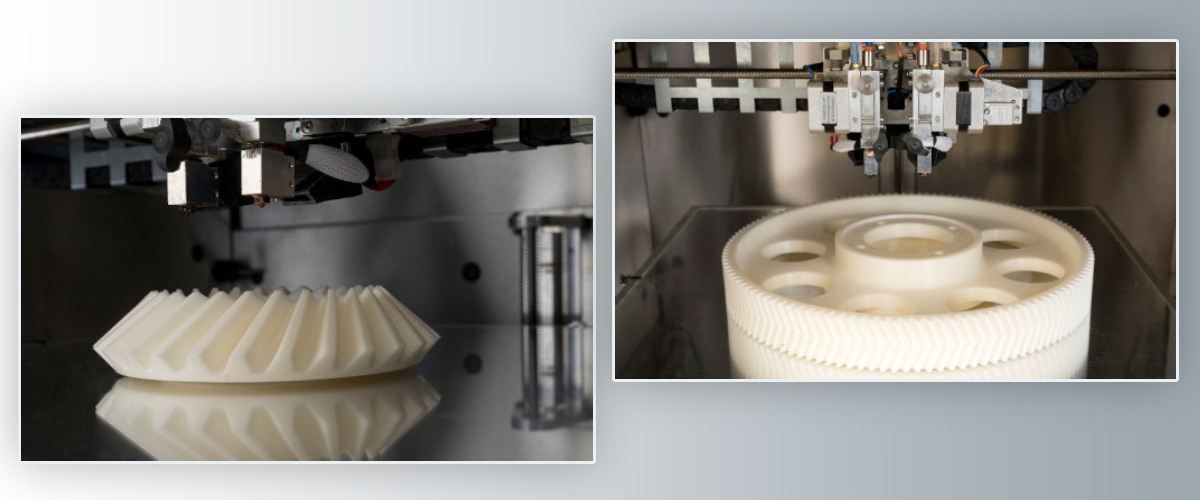

For those who want to buy an Omni NOVA 3D printer, this device will be the perfect choice for engineering 3D printing. Thanks to its high productivity, process automation and print quality. The Omni NOVA industrial 3D printer is designed for continuous operation at industrial facilities in various fields.

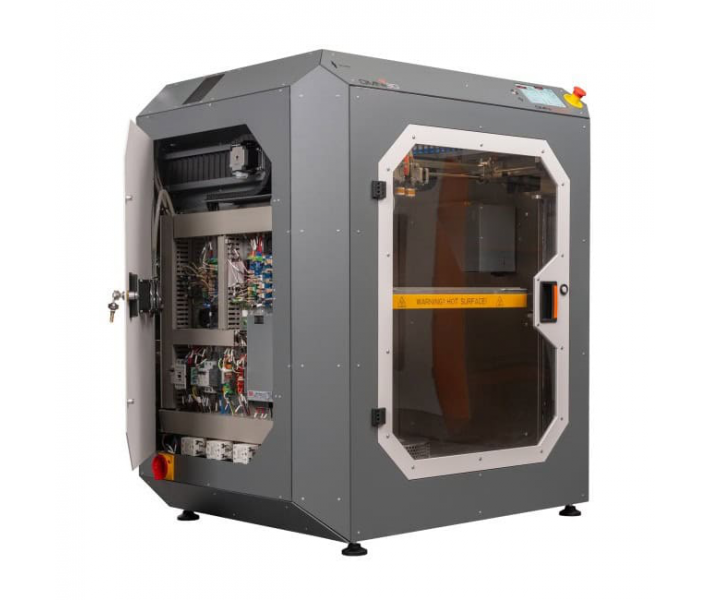

The device will help optimize resource and time costs, make 3D printing better and easier. Modern innovative electronic filling ensures efficient printing and high quality of finished products.

The improved work table is equipped with a two-zone heater. This ensures more uniform heating of the table, which has a positive effect on productivity and print quality.

Features of the Omni NOVA 3D printer

- Print area 500 * 500 * 570 mm.

- Automatic adjustment of 2 extruders.

- Simple and quick start of printing.

- Closed print chamber with heating.

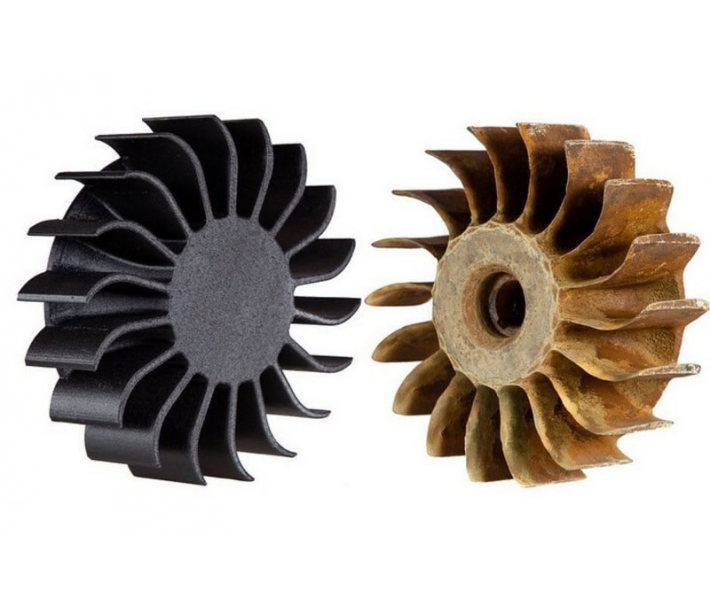

- Printing large parts from industrial thermoplastics.

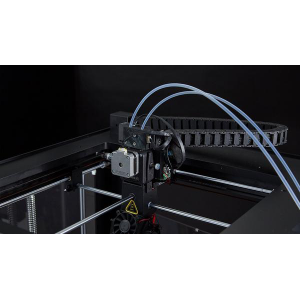

- Direct extruder cooling system.

- Temperature control of the print over its entire surface.

- Automatic extruder height control system.

- Automatic table leveling system.

- Print speed: 86 cm³/h.

- Head temperature: 360 °C (optional 420 °C).

- Table temperature: 150 °C (optional 170 °C).

- Temperature in the working chamber: 70 °C.

Industrial 3D printing starts with an innovative table

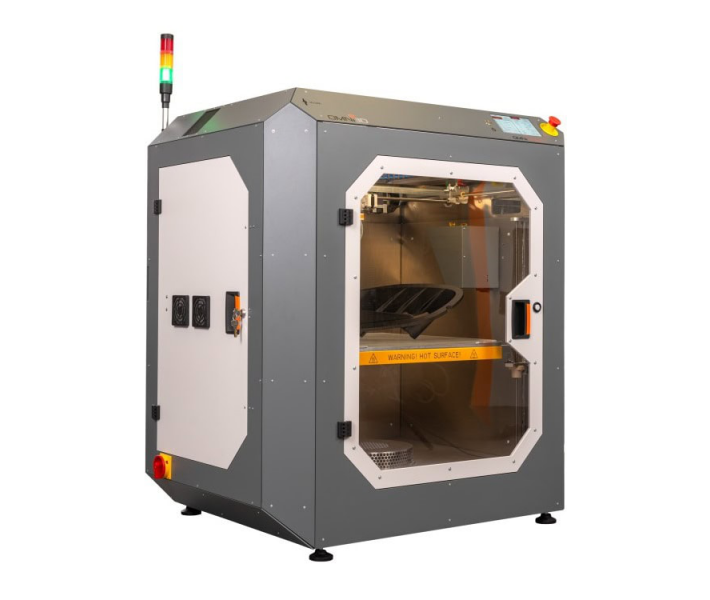

The perfect design and large size of the print table allows you to print several small parts or one large one. The dual-zone heater ensures uniform heating of the table.

Omni3D Platform Autoleveling System™ – automatic table leveling system. The system operates on 3 motors located on the Z-axis. They move the head, maintaining the specified printing parameters. The distance between the tip of the head and the platform is measured automatically throughout the printing process.

Adjustable printing temperature over the entire surface

Omni3D AirCirculation™ – the system regulates the printing temperature. A heated chamber and air circulation system are important for printing accurate and high-quality 3D models. Circulation of air flows inside the chamber ensures uniform temperature at all points of the chamber.

Automated Extruder Height Control

The Omni3D Head Leveling Control™ system in the Omni NOVA production 3D printer automatically calibrates the nozzles to the bed. Directly measuring the Z-axis distance between the right and left extruders helps align the height of the nozzles relative to each other. With this data, the 3D printer builds a more accurate mesh, taking into account the unevenness of the bed.

Filament presence and movement control in Omni NOVA

The Omni3D FilamentFlowControl™ Filament Flow Control System ensures repeatability and dimensional accuracy. Special encoders calculate the amount of material supplied and compare it with the amount specified in the 3D object file. When the parameters differ significantly, the printer issues a message to the user.

Innovative direct extruder cooling system

The Omni3D Cooling System™ allows the extruder to operate in a heated chamber and improves dimensional accuracy control during 3D printing. It reduces the temperature inside the filament feed channel by 40–60°C, which increases its rigidity and prevents softening. This allows for more precise control of the filament flow, as well as increases the speed and stability of the 3D printing process.

Buy an Omni NOVA 3D printer to get the benefits

Fast and accurate printing of single large models or a group of smaller models.

Automatic platform calibration.

Filament feed control.

2 extruders.

Closed working chamber with heating.

Omni NOVA Specifications | |

| Printing Technology | FFF |

| Minimum Layer Height (microns) | 50 – 600 |

| Construction Field (mm) | 500*500*570 |

| Ø Plastic (mm) | 1,75 |

| Max Nozzle Temperature (°C) | 360 (optional 420) |

| Number of Extruders | 2 |

| Working Chamber Type | Closed |

| Filament Chamber Type | Closed |

| Heating the Chamber | Yes |

| Drying Plastic | No |

| Autocalibration | Есть |

| Feed Mechanism Type | Direct |

| Extruder Design Type | Double head, electronic lifting system |

| Nozzle Diameter (mm) | 0.4, (0.6, 0.8 option) |

| Printing Accuracy (µm) | At 200 µm layer thickness, parts are produced with an accuracy of +/- 0.2 mm or 0.2% (whichever is greater) |

| Print speed | 86 см³/h |

| Maximum Chamber Temperature (°C) | 70 |

| Maximum Platform Temperature (°C) | 150 (optional 170) |

| Material and features of the Platform | Reusable sandwich structure with uniform heating, automatic calibration, glass ceramic working surface |

| Supported Materials | ABS, ABS-PC, AEROTEX, ASA, CAST, CARBON, CERAMO, ETERNAL, ELASTIK, FRICTION, FLEX, KAUCHUK, PRO-FLEX, HIPS, NYLON, PLA, PVA, PET, PC, ePC, РР, PETG, PPSU, PSU, PEI, PEEK, PEKK, PROTOTYPER SOFT, RELAX, RUBBER, SEALANT, SBS, SBS PRO, TPE, TPU, TOTAL PRO, ULTEM, ULTRAN, WAX, WOOD and others |

| Air filter | Carbon + HEPA (optional) |

| Control | 7″ LCD touch screen |

| Availability of a Video Camera | Yes |

| Peculiarities | Emergency shutdown, HEPA filter (optional), door sensor, end of thread sensor, power failure protection |

| Supported File Types | STL, OBJ, 3MF, GCODE, FACTORY |

| Software | Simplifi 3D |

| Connection | SD card, USB, Ethernet, WLAN |

| Nutritional requirements | 220 V±10%, 50/60 Hz, 2200 W |

| Country of Origin | Poland |

| Warranty Period (months) | 12 |

| Certificates | CE |

| Net Weight (kg) | 180 |

| Dimensions Net (mm) | 1070x770x1200 |

| Dimensions and weight in packaging | 1200 x 800 x 1410 mm, 242 kg |

| Operating Environment Temperature Range (°C) | 15 – 35 |

System requirements: The 3D printer works autonomously from an SD card. The Simplify3D software is installed on a computer with Windows, Linux, MacOS, and at least 2GB of RAM. The computer must be connected to the Internet at the time of activation.