- Stock: Inquire availability

- Product code: 00-00012999

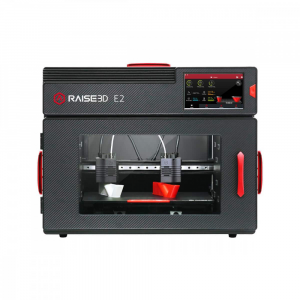

3D printing with metal-filled filaments – Raise3D MetalFuse system

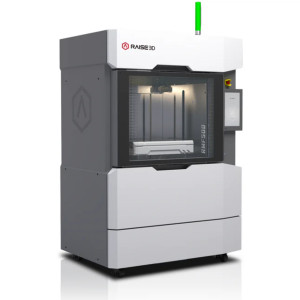

The Raise3D D200-E catalytic furnace for debinding. It is part of the new MetalFuse solution, which also includes the Forge1 large-format metal 3D printer and the S200-C vacuum sintering furnace. The system is aimed at high productivity, better repeatability, smooth post-processing, and environmental safety.

Raise3D D200-E catalytic debinder

With a working chamber of 200*200*200 mm, the D200-E furnace provides high productivity and exceptional quality of compound extraction. The machine can reach a speed of 1.55 mm/h. It is equipped with various intelligent features such as a hazard interlock, front-mounted E-stop, and activated carbon adsorption facilities. In addition, the device boasts mobility and a user-friendly design.

MetalFuse system

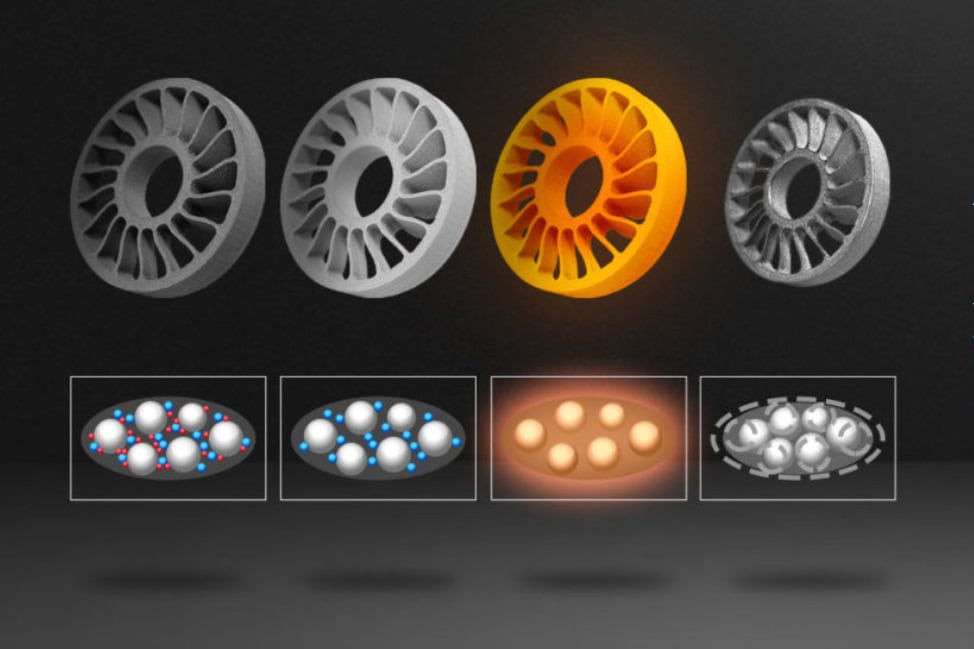

For best results, it is recommended to use the Raise3D D200-E as part of the MetalFuse system together with the Forge1 3D printer and S200-C. In this way, the polymer will be removed from the model during the catalytic bond removal process, resulting in a pure metal with no binder residue. The sintering process will further remove the binder due to the temperature below the melting point of the metal. This is how the product reaches its final hardness and strength.

Catalytic Debinding Process

The D200-E utilizes an oxalic acid-based catalytic debinding process. It is safe, environmentally friendly, easier than nitric acid treatment, and faster than solvent and thermal debinding. It can even be used for titanium and copper. With this method, the binder removal cycle takes much less time (4-12 hours instead of 12-72 hours). In addition, there are no restrictions on the height of the layer, and the residual fraction of the polymer is lower. Using a catalyst, it is possible to reduce time by 60% and at the same time obtain parts with a density of up to 97% of the level of wrought iron, which is 52% more compared to products obtained by solvent release.