-50 %

Formlabs Flame Retardant Resin Сartridge for Form 3, 1 kg, 0.84L

Formlabs Authorized Partner

3DDevice is an Authorized Partner of Formlabs in Ukraine

Price Incl. VAT

- Stock: In Stock

- Product code: 00-08800071

- Shipping Weight: 1.50kg

- SKU: RS-F2-FRGR-01

Based on 0 reviews.

-

Write a comment

₴7 722.00

₴15 385.00

Ex Tax: ₴7 722.00

Quantity:

Formlabs Flame Retardant resin for refractory elements

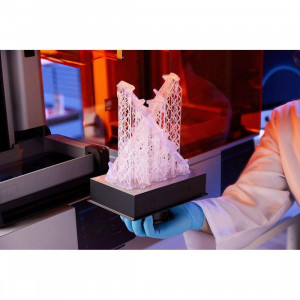

Flame Retardant Resin for 3D printing on Formlabs SLA 3D printers.

Flame Retardant Resin is a UL 94 V-0 certified specialty 3D printing material used to create self-extinguishing and halogen-free parts. It has excellent flammability, smoke and toxicity (FST) characteristics, making it ideal for printing parts that must meet stringent fire protection requirements.

Flame Retardant fire retardant resin: advantages

- Fast time to market. Allows rapid production of prototypes and final parts without the constraints of traditional manufacturing.

- Certified flame retardant. Parts printed with this flame retardant resin meet UL 94 V-0 and FAR 25.853 standards, making them suitable for use in environments with a high risk of fire.

- Heat and Warp Resistance. This material is resistant to high temperatures and stresses, making it ideal for use in harsh environments.

- High surface quality. Parts printed with FR Resin have a smooth and crisp surface, making them aesthetically pleasing and functional.

- Rigidity and functionality. Material has a modulus of elasticity of 2.9 GPa, making it a rigid and strong material suitable for mechanical loads.

Application

- Interior parts of airplanes, automobiles and railroads. Flame Retardant Resin can be used to print parts that must meet strict fire protection requirements and have high surface quality.

- Electronics. The resin is suitable for printing components for internal and protective consumer or medical electronics.

- Industrial parts. The material can be used to print specialty fixtures, fittings and replacement parts for industrial environments with high temperatures or sources of ignition.

Why choose Flame Retardant Resin?

FR Resin is a versatile and reliable material that offers a number of advantages for 3D printing parts that require flame resistance, heat and distortion, high surface quality and rigidity.

Specifications

| Printing Technology | SLA | |

| Polymerization | Needed | |

| Layer Height (micron) | Form 3/3+/3B/3B+ – 50, 100, Form 3L/3BL – 100 | |

| Printer Compatibility | Form 3/3+, Form 3B/3B+, Form 3L/3BL | |

| Resin Tank Compatibility | Form 3 V2/V2.1, Form 3L | |

| Build Platform Compatibility | Form 3 BP, Form 3 BP 2, Form 3 Stainless Steel BP, Form 3L BP, Form 3L BP 2L | |

| Volume (L) | 0.84 | |

| Manufacturer Country | USA | |

| Post-cured at 70ºC for 60 minutes | Post-cured at 80ºC for 120 minutes | |

| Heat Deflection Temperature 0.45 MPa | 94 ºC | 111 ºC |

| Heat Deflection Temperature 1.8 MPa | 71 ºC | 83 ºC |

| Tensile Modulus | 2,9 GPa | 3,1 GPa |

| Ultimate Tensile Strength | 38,5 MPa | 41,2 MPa |

| Elongation at Break | 9,4% | 7,1% |

| Notched Izod | 22,1 J/m | 22,4 J/m |

If you have any questions, please contact us.

Downloads

Technical Data Sheet, PDF (EN)

Buy in Ukraine refractory photopolymer for 3D printing

3D Printing

Printing Technology

SLA

Layer Height (µm)

Form 3/3+/3B/3B+ – 50, 100, Form 3L/3BL – 100

Details

Polymerization Needed

Yes

Printer Compatibility

Form 3/3+, Form 3B/3B+, Form 3L/3BL

Resin Tank Compatibility

Form 3 V2/V2.1, Form 3L

Build Platform Compatibility

Form 3 BP, Form 3 BP 2, Form 3 Stainless Steel BP, Form 3L BP, Form 3L BP 2L

Volume (L)

0.84

Country of Brand Registration

USA