- Stock: In Stock

- Product code: 00-00000254

- Shipping Weight: 1.50kg

- SKU: RS-F2-ESDS-01

Antistatic polymer Formlabs ESD Resin

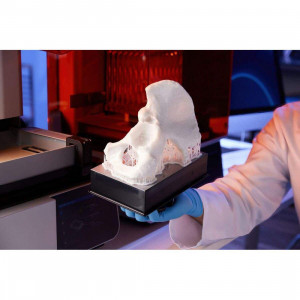

ESD Resin Formlabs is a cost-effective and efficient solution for the production of ESD-protected tooling and tooling. It is developed by Formlabs for 3D printing on all Formlabs 3D printers and is designed to create models with the ability to dissipate static electricity for electronics and other applications where protection from the buildup of static charge is needed.

ESD resin parts safely dissipate static electricity and repel dust and powder. This makes ESD Resin an ideal material for the production of reliable custom parts that meet ESD safety standards. It is used to create: antistatic prototypes and final parts, housings for protecting sensitive electronics from electrostatic discharges, tooling, tools, fixtures and similar parts designed for long-term use in the factory.

- Supported print resolution: 100 µm, 50 µm.

- Final polymerization is required.

Advantages

Use two key features of ESD polymer in your production:

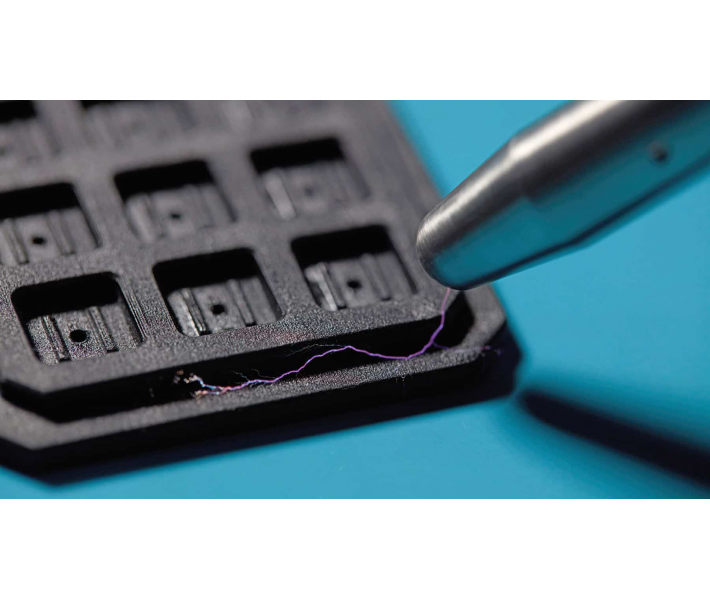

- Dissipation of electrostatic discharges. Critical electrical components are protected from ESD and failure.

- High strength. ESD Resin has a high tensile modulus of 1.937 GPa and an impact strength of 26 J/m. This makes it ideal for industrial applications.

Application of ESD Resin

Static electricity is a problem in the manufacturing industry. Materials that accumulate static electricity can discharge near conductive materials, causing damage to electronics and other sensitive components.

Most plastics, including Formlabs resins, are insulators. They can store static electricity and discharge it on contact with conductive materials. Formlabs ESD Resin is specifically designed to safely dissipate static electricity, making it ideal for producing durable custom parts that meet ESD safety standards.

Ensure ESD resin parts are properly grounded to prevent damage to components they may come into contact with. Use materials such as antistatic mats or grounding cables to ensure that static charges are safely dissipated.

When grounded, static dissipative materials allow electrical charges to pass through, allowing electrons to travel across the surface to the ground point. An additional advantage of such materials is antistatic properties, due to which small particles, such as dust, powder and polystyrene foam, do not stick to them. The accumulation of contaminants often leads to the failure of fragile electrical and mechanical systems. Manufacturers have traditionally protected equipment from static electricity buildup through metalworking. However, now you can use 3D printing for this.

Why choose ESD Polymer

Using ESD Resin polymer for 3D printing in your production, you:

- Cost-effectively build customized ESD-protected manufacturing tools..

- Cheaply test workflows for electronics manufacturing and printing shockproof parts by prototyping with ESD Resin.

- Reduce risks and increase work efficiency.

- Increase the productivity of your electronics production lines.

- Expand production with 3D printed durable fixtures and fittings for automotive, aerospace and electronics industries.

Comparison with other materials

Surface resistivity measures the resistance to current flowing across the surface of a material. The higher the resistivity, the less conductive the material. ESD Resin is more conductive than other Formlabs resins, allowing electrical charges to flow in a controlled manner.

See the table below for a comparison of the respective material properties:

| ESD Resin | Tough 2000 Resin | |

| Surface resistivity, Om/cm2 | 105 – 108 | > 1012 |

| Tensile strength, MPa | 44 | 46 |

| Tensile modulus, GPa | 1,937 | 2,140 |

| Elongation at break, % | 12 | 45 |

| IZOD Impact strength, J/m | 26 | 40 |

| Thermal deflection temperature (HDT) at 1.8 MPa, °C | 54,2 | 62,0 |

| Thermal Deflection Temperature (HDT) HDT at 0.45 MPa, °C | 62,2 | 53 |

Post-processing

Form Wash options. Flush ESD Resin parts for 20 minutes. Do not leave ESD Resin in the solvent for more than 20 minutes to avoid damaging the model. We recommend washing ESD Resin separately from other resins to prevent staining.

Form Cure options. ESD Resin parts should be cured for 60 minutes at 70°C to achieve the best physical properties.

ESD Resin Material Properties Table

| Post-cured 1,2 | Method | |

| Mechanical properties | ||

| Ultimate Tensile Strength | 44,2 MPa | ASTM D 638-14 |

| Tensile Modulus | 1,937 GPa | ASTM D 638-14 |

| Elongation at Break | 12% | ASTM D 638-14 |

| Flexural Properties | ||

| Flexural strength | 61 MPa | ASTM D 790-17 |

| Flexural Modulus | 1,841 GPa | ASTM D 790-17 |

| Impact Properties | ||

| Notched IZOD | 26 J/m | ASTM D 256-10 |

| Notched IZOD | 277 J/m | ASTM D 4812-11 |

| Thermal Properties | ||

| Heat Deflection Temp. @ 1.8 MPa | 62,2 °C | ASTM D 638-18 |

| Heat Deflection Temp. @ 0.45 MPa | 54,2 °C | ASTM D 638-18 |

| Thermal Expansion | 123,7 μm/m/°C | ASTM E 813-13 |

| Electrical Properties | ||

| Surface Resistivity | 105 – 108 Om/cm2 | ANSI/ESD 11.11 3 |

| Volume Resistivity | 105 – 107 | ANSI/ESD 11.11 3 |

| Physical Properties | ||

| Density | 1,116 g/cm3 | ASTM D792 |

| Hardness | 90D by Shore | ASTM D2240 |

1 Material properties may vary based on part geometry, print orientation, print settings, temperature, and disinfection or sterilization methods used.

2 Data for post-cured samples were measured on Type IV tensile bars printed on a Form 3 printer with 100 µm ESD Resin settings, washed in a Form Wash for 20 minutes in ≥99% Isopropyl Alcohol, and postcured at 70°C for X 60 minutes in a Form Cure.

3 ESD Resin was tested at NAMSA World Headquarters, OH, USA.

Formlabs ESD Resin Solvent Compatibility

Weight percentage increase in 24 hours for a printed and post-cured 1x1x1 cm cube immersed in an appropriate solvent:

| Solvent | 24 hr weight gain, % | Solvent | 24 hr weight gain, % |

| Acetic Acid 5% | 0.5 | Mineral oil, heavy | 0.1 |

| Acetone | 13.1 | Mineral oil, light | 0.1 |

| Bleach 5% NaOCl | 0.5 | Solt water (3.5% NaCl) | 0.6 |

| Butyl Acetate | 3.8 | Skydrol 5 | 0.5 |

| Diesel Fuel | 0.2 | Sodium hydroxide solution (0.025% pH = 10) | 0.7 |

| Diethyl glycol monomethyl ether | 3.6 | Strong Acid (HCl Conc) | 1.4 |

| Hydraulic Oil | 0.2 | TPM | 0.6 |

| Hydrogen peroxide 3% | 0.6 | Water | 0.7 |

| Isooctane | < 0.1 | Xylene | 1.6 |

| Isopropyl Alcohol | 2.6 |