- Stock: In Stock

- Product code: 00-00000268

- Shipping Weight: 1.50kg

- SKU: RS-F2-BMBL-01

Biocompatible polymer BioMed Black Resin

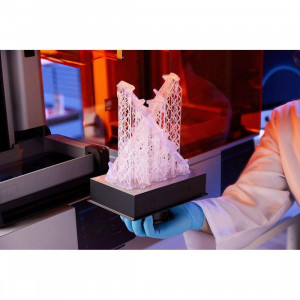

Biocompatible polymer Formlabs BioMed Black Resin is designed specifically to improve the quality of care. Modern tools are available for every medical institution in just a few hours – with 3D printing using Formlabs medical polymers.

Formlabs is constantly expanding its range of materials for its 3D printers. The Formabs family of biomedical resins is designed for a wide range of applications where performance and biocompatibility are critical. BioMed Resin materials are developed and manufactured at an ISO 13485 certified plant and are compatible with conventional disinfection and sterilization methods.

Additive production in medicine

BioMed Black Resin is a solid matte biocompatible photopolymer that is used in cases where expected a prolonged skin contact or short-term contact with the patient’s mucous membrane.

Models printed with BioMed Black Resin can be treated with conventional solvent disinfection and sterilization methods. BioMed Black Resin is manufactured by an ISO 13485 certified and USP Class VI certified company. Thus, the material is safe for use in pharmaceuticals and drug delivery.

- Printing resolution: 100 microns, 50 microns.

- Final polymerization is required.

BioMed Black Resin usage

Medical polymer BioMed Black Resin is a fast 3D printing of sterilizable and biocompatible objects:

- Medical devices and their components.

- Biocompatible molds.

- Clamping and fastening devices.

- The final models that involve contact with the skin.

- Consumer goods.

Data properties of BioMed Black Resin:

| Post-Cured1,2 | Method | |

| Tensile Properties | ||

| Ultimate Tensile Strength | 37,51 MPa | ASTM D 638-10 (Type IV) |

| Young’s Modulus | 1523,74 MPa | ASTM D 638-10 (Type IV) |

| Elongation | 14% | ASTM D 638-10 (Type IV) |

| Flexural Properties | ||

| Flexural Stress at 5% Strain | 57,16 MPa | ASTM D 790-15 (Method B) |

| Flexural Modulus | 1668,53 MPa | ASTM D 790-15 (Method B) |

| Hardness Properties | ||

| Hardness Shore D | 77D | ASTM D 2240-15 (Type D) |

| Impact Properties | ||

| Notched IZOD | 24,77 J/m | ASTM D 256-10 (Method A) |

| Unnotched IZOD | 348,03 J/m | ASTM D 4812-11 |

| Thermal Properties | ||

| Heat Deflection Temp. @ 1.8 MPa | 49,4 °C | ASTM D 648-18 (Method B) |

| Heat Deflection Temp. @ 0.45 MPa | 67,9 °C | ASTM D 648-18 (Method B) |

| Coefficient of Thermal Expansion | 106,9 mkm/m/°C | ASTM E 831-13 |

| Other Properties | ||

| Water Absorption | 0,44 wt% | ASTM D570-98 |

Sterilization and disinfection of BioMed Black Resin products

| Sterilization Compatibility | |

| E-beam | 35 kGy E-beam radiation |

| Ethylene Oxide | 100% Ethylene oxide at 55 °C for 180 minutes |

| Gamma | 29.4 – 31.2 kGy gamma radiation |

| Steam Sterilization | Autoclave at 134°C for 20 minutes Autoclave at 121°C for 30 minutes |

| Disinfection Compatibility | |

| Chemical Disinfection | 70% Isopropyl Alcohol for 5 minutes |

Biocompatible polymer for medical use

Samples printed with BioMed Black Resin were evaluated according to the following biocompatibility standards:

| ISO Standard | Description3 |

| ISO 10993-5:2009 | Not cytotoxic |

| ISO 10993-10:2010/(R)2014 | Not an irritant |

| ISO 10993-10:2010/(R)2014 | Not a sensitizer |

The product was developed and is in compliance with the following ISO Standards:

| ISO Standard | Description |

| EN ISO 13485:2016 | Medical Devices – Quality Management Systems – Requirements for Regulatory Purposes |

| EN ISO 14971:2012 | Medical Devices – Application of Risk Management to Medical Devices |

Compatibility with solvents

Percent weight gain over 24 hours for a printed and post-cured 1 x 1 x 1 cm cube immersed in respective solvent:

| Solvent | Increase after 24 hours, % | Solvent | Increase after 24 hours, % |

| Acetic Acid, 5 % | 0,3 | Mineral oil, heavy | 0,2 |

| Acetone | 3,1 | Mineral oil, light | 0,2 |

| Bleach ~5% NaOCl | 0,2 | Salt Water (3.5% NaCl) | 0,3 |

| Butyl Acetate | 0,4 | Skydrol 5 | 0,6 |

| Diesel Fuel | 0,1 | Sodium hydroxide solution (0.025% pH = 10) |

0,3 |

| Diethyl glycol monomethyl ether | 1,0 | Strong Acid (HCl Conc) | 0,2 |

| Hydraulic Oil | 0,2 | TPM | 0,6 |

| Hydrogen peroxide (3%) | 0,3 | Water | 0,3 |

| Isooctane | < 0,1 | Xylene | 0,3 |

| Isopropyl Alcohol | 0,2 |

1 Material properties may vary based on part geometry, print orientation, print settings, temperature,

and disinfection or sterilization methods used.

2 Data were measured on post-cured samples printed

on a Form 3B with 100 µm BioMed Black Resin settings, washed in a Form Wash for 5 minutes in 99% Isopropyl

Alcohol, and post-cured at 60 °C, 60 minutes in a Form Cure.

3 BioMed Black Resin was tested at

NAMSA World Headquarters, OH, USA.

Buy Resins for 3D printing on Formlabs Form 3B+ printer

3DDevice is the official representative of Formlabs in Ukraine and Moldova. Here you can buy the latest models of SLA 3D printers. Super-accurate 3D printing with reproducible results with a wide range of special Formlabs photopolymers.