Оновлення PreForm 3.34.0 розширює можливості 3D-друку

Нова версія програмного забезпечення Formlabs PreForm 3.34.0 розкриває нові можливості для 3D-друку як за технологією SLA, так і SLS.

Для Fuse 1+ 30W:

- Швидкість друку на 25% вища, ніж у попередній версії програмного забезпечення, і в три рази швидше, ніж у оригінального Fuse 1.

- 95% завдань з друку порошком Nylon 12 будуть виконані менш ніж за 14 годин, а типові збірки завершуються лише за 7 годин.

Для серії Form 3:

Оновлення PreForm 3.34.0 також включає:

- Нові параметри робочого процесу, що свідчать про прагнення Formlabs до постійного вдосконалення екосистеми SLA та SLS-друку.

- Вдосконалення на основі відгуків користувачів, щоб зробити принтери Formlabs потужними та надійними інструментами для втілення ваших ідей в життя.

Завантажте PreForm 3.34.0, щоб розширити можливості вашого 3D-друку!

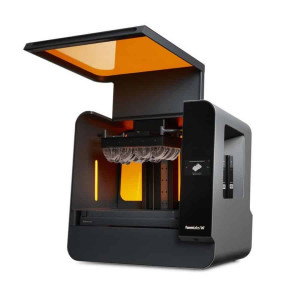

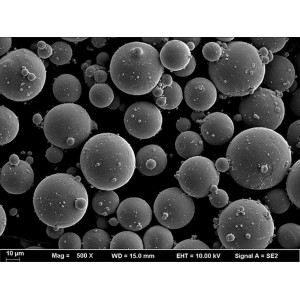

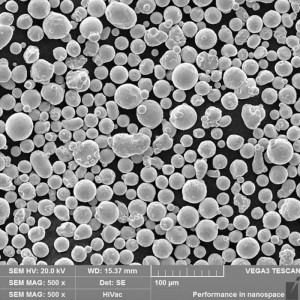

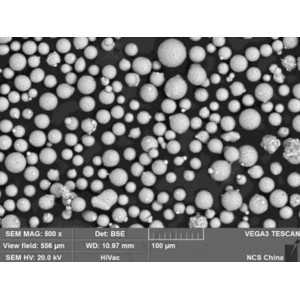

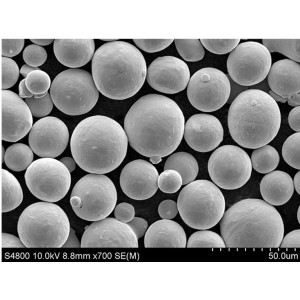

Fuse 1+ 30W – лідер швидкості у SLS-друці

PreForm 3.34.0 забезпечує швидший і ефективніший процес друку SLS із швидкістю друку на 25% вищою, ніж останнє оновлення програмного забезпечення, і вдвічі швидшою, ніж усі інші настільні принтери SLS. Клієнти SLS можуть витрачати менше часу на очікування деталей і більше часу на проектування, тестування та інші важливі завдання.

Це оновлення програмного забезпечення збільшує швидкість друку, підвищуючи ефективність шаблону сканування лазера, який рухається по верхньому шару порошку, спікаючи частинки разом у поперечний переріз потрібної форми.

Попередня версія:

- Лазер рухався лінійно зліва направо, зупиняючись, прокручуючи назад і повторюючи рух.

- Фігури, розділені простором, друкувалися, але лазеру доводилося зупинятися між сегментами та в кінці рядків.

- Зупинки лазера призводили до втрати часу.

Оновлена версія:

- Траєкторія лазера оптимізована для кращої ефективності.

- Лазер уникає тривалих пауз, забезпечуючи безперервну роботу.

- Файли для друку на 90% менші, що спрощує роботу.

Переваги:

- Підвищення продуктивності:

- Контрактні виробники можуть друкувати більше завдань за один час.

- Настільні принтери SLS стають конкурентоспроможними з промисловими.

- Прискорення прототипування:

- Дизайнери можуть швидше тестувати та вдосконалювати свої ідеї.

- Економічна вигода:

- 3D-друк стає більш конкурентоспроможним для малих і середніх обсягів виробництва.

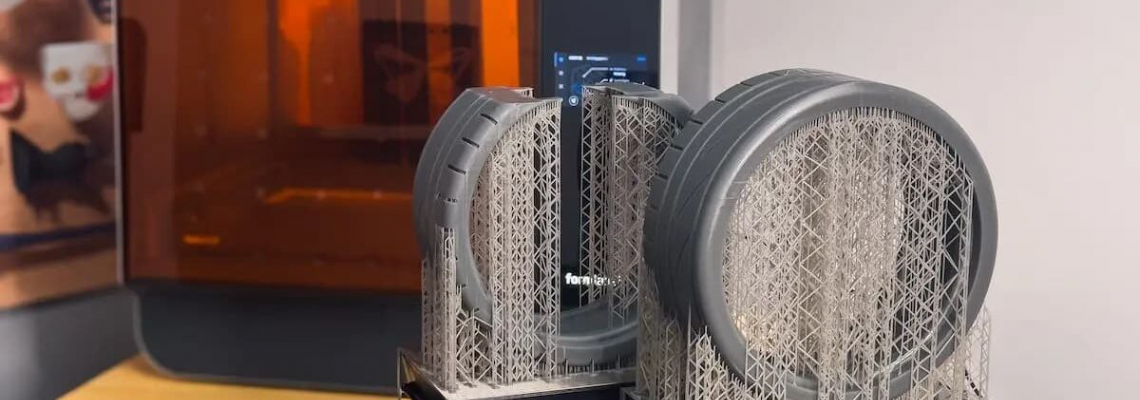

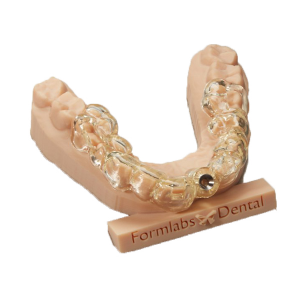

Збільшено розмір друку SLA

Для клієнтів Formlabs SLA обсяг збірки раніше був обмежений, щоб гарантувати, що кожну деталь можна було легко вийняти з принтера без будь-якого шансу, що деталь вдариться в резервуар для смоли або зачепить край принтера. Незважаючи на те, що це обмеження допомагає обмежити потенційне пошкодження деталей, багато клієнтів запитували спосіб перевизначити ці засоби захисту та створити більші деталі, які використовують якомога більший об’єм збірки.

Завдяки цим новим параметрам тепер ви можете друкувати до 4% вищих деталей на Form 3/B/+. Доступна висота тепер становить 193 мм порівняно з попередніми 185 мм. На Form 3L/BL тепер можна друкувати до 7% вищих деталей. Доступна висота тепер становить 320 мм порівняно з 300 мм раніше.

| Попередня Максимальна Висота Друку | Нова Максимальна Висота Друку | % Збільшення | |

| Form 3/B/+ | 185 мм | 193 мм | 4% |

| Form 3L/3BL | 300 мм | 320 мм | 7% |

Важливо проявляти особливу обережність, видаляючи високі відбитки з принтера. Переконайтеся, що відбиток не торкається стінки бака; можливо, вам знадобиться вийняти резервуар і друкувати одночасно для плавного вилучення.

Виходячи з властивостей матеріалу, деякі смоли та налаштування друку краще оптимізовані для високого друку. Хоча високий друк доступний для більшості смол Formlabs, він не рекомендований для наступних смол при друку 100 мікрон:

- Silicone 40A Resin (Form 3/B/+)

- BioMed Amber Resin (Form 3/B/+)

- Surgical Guide Resin (Form 3/B/+)

- Rigid 10K Resin (Form 3L/BL)

Автоматичні оновлення для Windows і підтримка Fuse Blast

Крім покращення швидкості та розміру, PreForm 3.34.0 полегшує користувачам Windows залишатися в курсі останніх налаштувань програмного забезпечення. Для користувачів Windows PreForm автоматично оновлюватиметься, якщо програмне забезпечення відкрито, і оновлюватиметься протягом ночі, якщо воно не використовується. Звичайно, для клієнтів із підтвердженими робочими процесами ми розуміємо, що ваш процес має залишатися абсолютно послідовним: цю функцію автоматичного оновлення можна вимкнути в налаштуваннях PreForm.

PreForm 3.34.0 також полегшує користувачам серії Fuse нагляд за повною екосистемою SLS за допомогою оновлень прошивки Fuse Blast і завантажень журналів. Використання Fuse Blast для очищення відбитків SLS скорочує робочий час і витрати на деталь, а також покращує якість поверхні. Оновлення до останньої версії PreForm покращує нагляд і моніторинг процесу Fuse Blast.

Постійне вдосконалення на основі ваших відгуків

Принтери, матеріали та програмне забезпечення Formlabs – це інструменти, які переносять ідеї наших клієнтів від файлу до готової деталі, і інструменти завжди повинні розроблятися з урахуванням процесу кінцевого користувача. Працюючи з нашими користувачами, щоб зрозуміти їхні унікальні робочі процеси, ми можемо створювати продукти, які зосереджуються на результатах.

Серія Fuse представляє доступну промислову якість SLS, і завдяки збільшенню швидкості користувачі серії Fuse можуть зрівнятися з більш дорогими традиційними системами 3D-друку з порошковим шаром. Збільшивши великий об’єм Form 3L, ми можемо задовольнити потреби клієнтів у деталях людського масштабу з кінцевим оздобленням.

Щоб зв’язатися з нашими експертами та обговорити технології та матеріали, які найкраще підходять для вашого унікального робочого процесу, зв’яжіться з нашою командою.

Залишити коментар