- Stock: In Stock

- Product code: 00-08800235

- Shipping Weight: 1.30kg

Available Options

Hyper Speed ABS filament for high-speed 3D printing

Raise3D Hyper Speed ABS filament is one of the specially developed materials in the Raise3D line for high-speed FFF 3D printing.

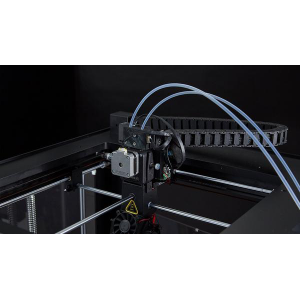

During high-speed printing, the filament is quickly fed into the thermal block, where the polymer must melt without delay to avoid clogging nozzles and poor bonding between the layers. And during high-speed printing without heating the chamber, ABS can easily deform and delaminate.

Raise3D Hyper Speed ABS solves these problems with its optimized molecular weight and stiffness, which allows for faster melting and cooling, reducing temperature gradient and internal stress. In addition, HS ABS has improved interlayer bonding and no warping, making it ideal for functional parts, tools and prototypes with many possibilities for further processing.

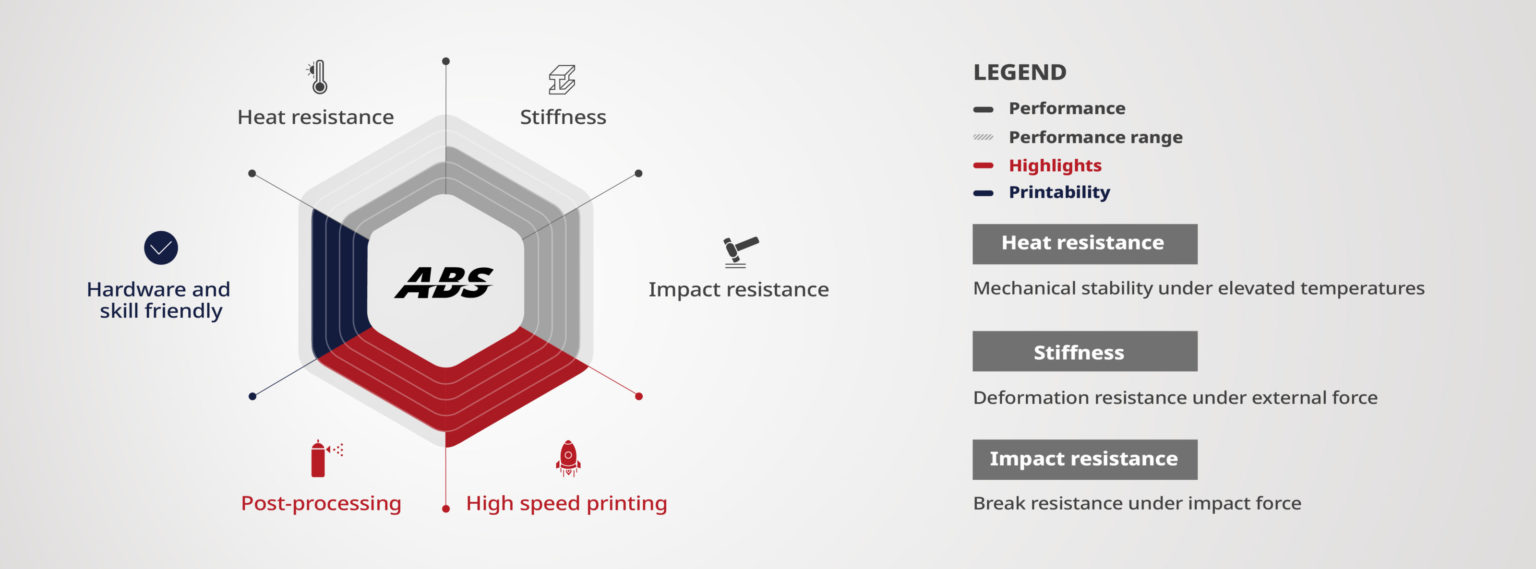

HS ABS Raise3D main features

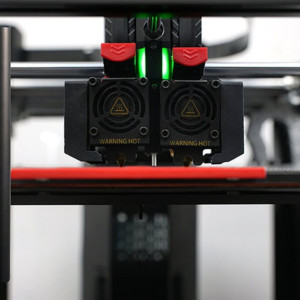

- Designed for high-speed printing

- High fluidity

- Parts without deformation

- Higher dimensional stability

- Excellent impact resistance

- Improved interlayer bonding

Hyper Speed ABS filament application

- High speed 3D printing

- Prototyping and conceptual models

- Functional prototyping

- Tools and fixtures

Recommended printing parameters

- Nozzle temperature: 210 – 260 °C

- Print bed temperature: 55 – 65 °C

- Layer height: 0.1 – 0.2 mm

- Printing speed: 25 – 300 mm/s

- Cooling fan: On

- Drying temperature: 50 °C

Features of printing with high-speed ABS

- For better adhesion to the bed and less chance of distortion of parts, it is recommended to add an brim or raft.

Specifications

| Filament diameter (mm) | 1.75 |

| Material | HS ABS |

| Density (g/cm3) | 1.08 |

| Print temperature (°C) | 210 – 260 |

| Heated table | Necessary |

| Table temperature (°C) | 55 – 65 |

| Closed Camera | Recommended |

| Cooling (%) | Low or off |

| Print speed (mm/s) | 25 – 300 |

| Drying conditions | 50 °C |

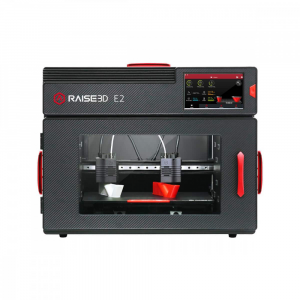

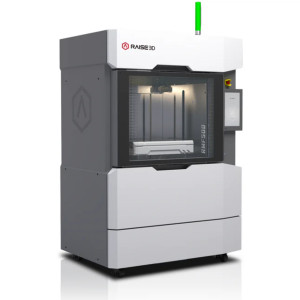

| Compatibility with the printer | Pro3, Pro3 Plus |

| Producing country | China |

| Weight of Plastic (kg) | 1.0 |