- Stock: In Stock

- Product code: GEN-38126323

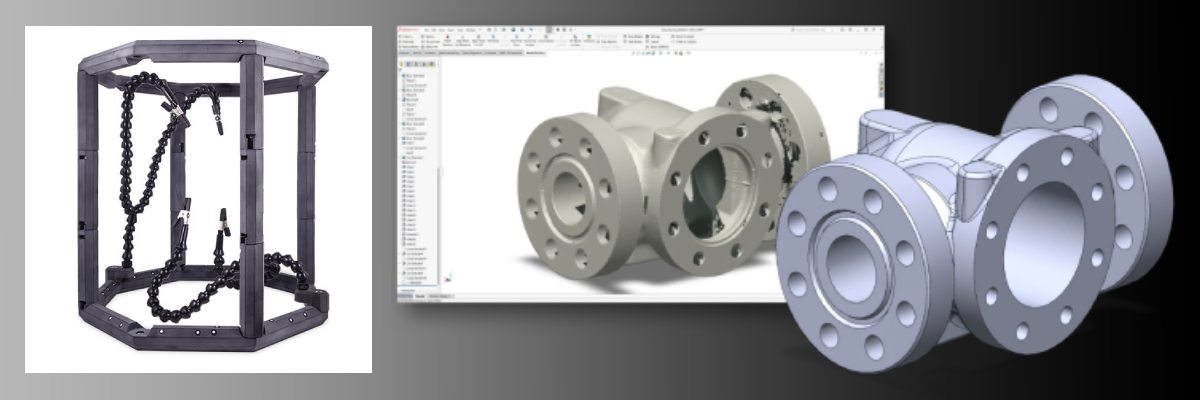

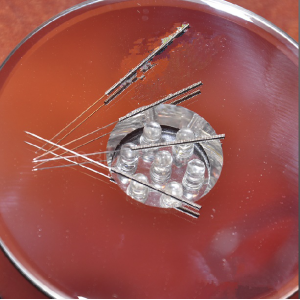

AESUBframe 300 Carbon Fiber Scanning Frame – Disassemblable Design

AESUBframe 300 Carbon Fiber Scan Frame scanning frame with a diameter of 300 mm is made of carbon fiber. It is a lightweight and robust design, ideal for precise scanning of medium-sized objects. The modular assembly allows the frame to be quickly adapted to various tasks. Using the frame in combination with AESUBdots reflective marks ensures optimal scanning conditions.

Advantages

- Extremely lightweight and rigid design: guarantees comfortable handling and stability when scanning.

- Modularity: easy to assemble and adjust thanks to extensions and holders.

- High accuracy: ideal for eliminating artifacts and ensuring high-quality data.

Applications

- Scanning objects with deep pockets to eliminate artifacts in the data.

- Scanning transparent surfaces where it is necessary to prevent light from passing through.

- Working with reflective elements to minimize focused reflections.

Package includes

- 2 frames with a diameter of 300 mm.

- 8 screw extensions of 100 mm.

- 4 extension rods for clamps of 100 mm.

- 2 metal handles with crocodile clips.

- 2 holders for metal hands.

- 4 crocodile clips.

- 1 Allen key.

Recommendation for using

- Scanning spray will further improve the quality and eliminate unwanted reflections.

- Using scanning targets also improves the quality of the scanning results.

- AESUBframe 300 – the perfect choice for professional 3D scanning

Frames for improving the 3D scanning process are used in various fields

Their use significantly improves the quality and accuracy of the resulting 3D models, especially when working with complex objects. Frames significantly speed up the scanning process and increase the accuracy of the resulting scans in the following cases:

- Resolving problems with reflective surfaces. When scanning objects containing reflective parts, such as mirrors or polished metals, the problem of directional light reflection arises. Light rays are reflected in a focused manner, which means that only a small part of them falls back on the scanner sensor. As a result, the scanner may capture incomplete data about the object.

- Scanning objects with deep recesses. Objects with complex geometry that have deep pockets can also create difficulties when scanning. In such cases, the scanner registers reflections not only from the surface of the object, but also from the inner walls of the recesses. This leads to distortion of the light pattern and the appearance of artifacts or incorrect data in the final 3D model.

Improving accuracy with a matting spray

To achieve high quality and accuracy of scanning, it is recommended to use a special matting spray. You can choose a matting spray in the 3D accessories category. This spray creates a thin matte white coating on the surface of the object, which effectively eliminates factors such as:

- Differences in surface color.

- Uneven light reflection.

- Texture heterogeneity.

The matte coating provides ideal conditions for scanning, minimizing reflections and other interference, which allows you to get the most accurate and detailed 3D models.

Using frames in combination with a matting spray is the optimal solution for obtaining high-quality 3D scans of even the most complex objects.