- Stock: In stock (14-day delivery)

- Product code: 00-00013444

- Shipping Weight: 1.13kg

Creaform HandySCAN PRO: Professional Solution for High-Precision 3D Scanning

In today's manufacturing environment, where precision and speed of quality control play a crucial role, the HandySCAN PRO from Canadian company Creaform has established itself as a reliable tool for professional 3D scanning. This portable metrology scanner is designed for use in the most demanding industrial conditions, where high measurement accuracy and flexibility of use are required.

Purpose and Applications

HandySCAN PRO is designed to solve a wide range of tasks in quality control, reverse engineering, and product inspection. The scanner finds application in:

- Automotive Industry – for controlling part geometry, inspecting dies and tooling, analyzing gaps and fits of body elements.

- Aerospace Sector – where measurement accuracy of aircraft components and satellite equipment is critically important.

- Mechanical Engineering – for verifying manufactured parts against CAD models, inspecting welded joints and complex structures.

- Consumer Goods Manufacturing – for quality control of plastic products, packaging, and design prototypes.

- Energy Sector – for inspection of turbines, blades, and other critical equipment.

Key System Features

Portability and Autonomy

HandySCAN PRO is a truly portable tool that does not require a stationary workplace or controlled measurement laboratory conditions. The scanner can be used directly on the production floor, in warehouses, or even in field conditions. This mobility significantly reduces the time spent transporting large parts to measuring equipment.

Metrological Accuracy

The system provides a metrological level of accuracy that meets the strictest industrial standards. HandySCAN PRO can detect even minimal deviations from nominal dimensions, making it indispensable for inspecting critical parts and assemblies.

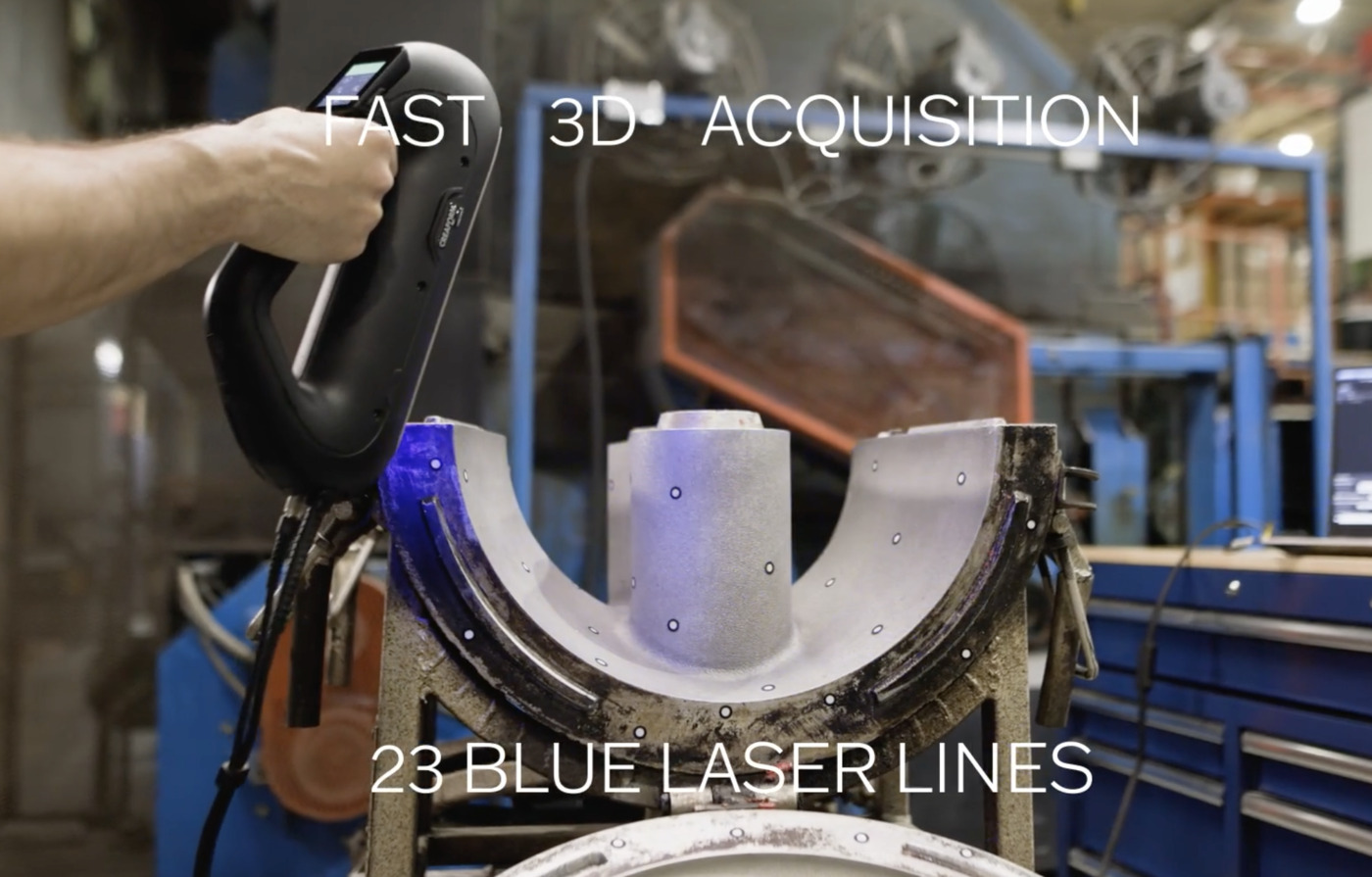

Digitization Speed

The high-performance scanning process allows obtaining complete 3D models of complex objects in just minutes. This is particularly important in production environments where equipment downtime must be minimized.

Versatility

The scanner works effectively with objects of various sizes – from small components to large-scale structures. The system handles complex geometry, organic shapes, and technical surfaces equally well.

Technological Advantages

Independence from Environmental Conditions

One of the most important features of HandySCAN PRO is its ability to work in real production conditions. The scanner is insensitive to vibrations, temperature fluctuations, and lighting typical of shop floor environments. This ensures stable results without the need to create special measurement conditions.

No Object Preparation Required

Unlike many other systems, HandySCAN PRO does not require coating objects with special materials or installing additional markers in most cases. This accelerates the work process and allows scanning objects without risk of damage or contamination.

Self-Positioning

Dynamic referencing technology allows the scanner to automatically determine its position relative to the object. This means that the operator can freely move around the part, scan it from different angles, and the system will independently combine all data into a single accurate 3D model.

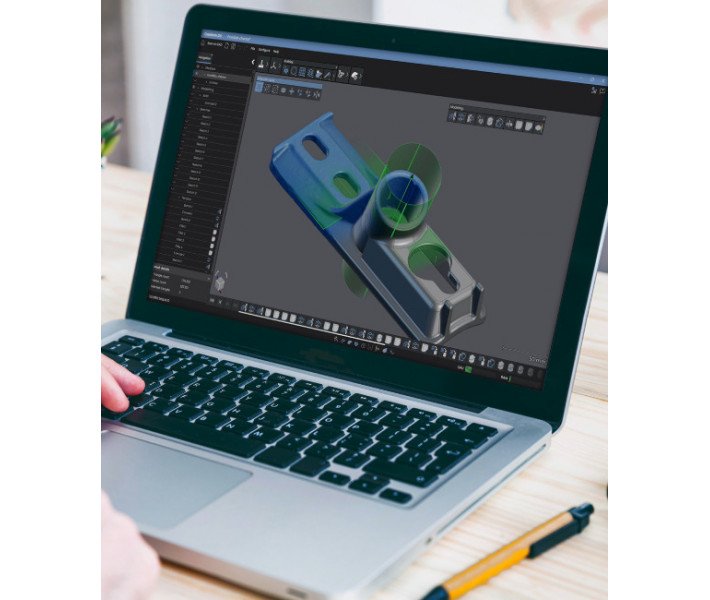

Integration with CAD/CAM Systems

The obtained 3D data can be directly exported to popular CAD and inspection software. This enables detailed deviation analysis, compliance report generation, and use of scanned data for reverse engineering.

Practical Manufacturing Benefits

Reduced Quality Control Time

Traditional measurement methods using coordinate measuring machines (CMMs) require considerable time for part setup, measurement program creation, and actual measurement. HandySCAN PRO allows obtaining a complete picture of object geometry in a fraction of this time.

Improved Product Quality

The ability to quickly and accurately check parts at all production stages allows detecting deviations at early stages and promptly adjusting the technological process. This leads to reduced defects and rework.

Economic Efficiency

While HandySCAN PRO represents a professional-level investment, the system quickly pays for itself through increased quality control productivity, reduced defect rates, and the ability to perform tasks that were previously technically difficult or impossible.

Documentation and Archiving

3D scans create a digital archive of products that can be used for analyzing changes during operation, creating spare parts, or modernizing designs. This is particularly valuable for long-term projects and maintaining legacy equipment.

Ease of Use

Despite the high-tech nature of the system, HandySCAN PRO is designed with operator convenience in mind. Ergonomic design, intuitive VXelements software, and the possibility of rapid personnel training make the system accessible even for users without deep metrology knowledge.