- Stock: Inquire availability

- Product code: 00-08800237

- Shipping Weight: 0.75kg

Polypropylene for 3D printing on Raise3D printers

Polypropylene for 3D printing P-filament 721 from PPrint is selected and certified by Raise3D specialists for 3D printing on Raise3D printers.

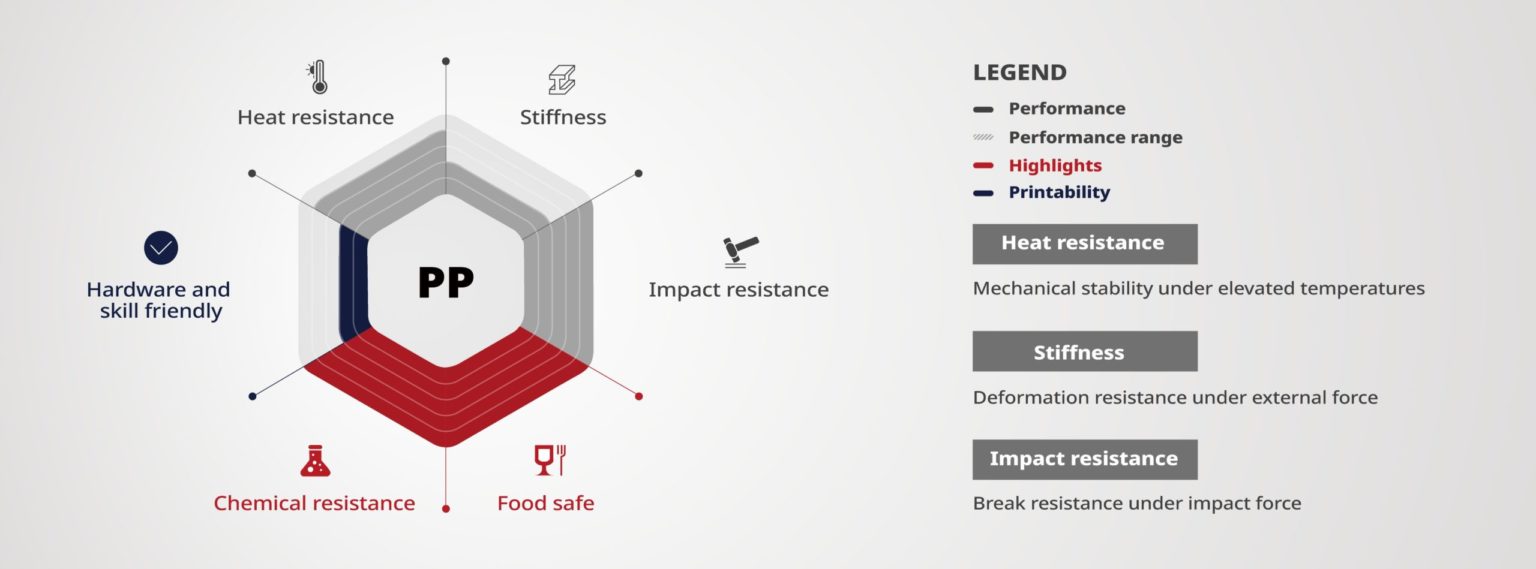

Polypropylene is a thermoplastic filament for 3D printing that is widely used in everyday life. It is known for its elasticity, strength, resistance to tearing and fatigue. Due to its low density, PP is ideal for lightweight structures. Printed parts made of PP easily bend, twist or crumple. This material has a wide range of applications, as polypropylene is used to make safe food, chemical and medical products, including orthopedic applications, due to its lightness and low coefficient of friction.

FDM 3D printer plastic P-filament 721, based on polypropylene, is well suited for 3D printing, providing excellent printer performance with low distortion and shrinkage combined with extremely high layer adhesion. Parts printed with P-filament 721 are highly tear-resistant, have excellent mechanical properties, excellent chemical resistance and temperature stability, and low friction resistance. This thread can be used to realize a variety of applications – from technical components to individual decorative and artistic objects to toys. The food safety of the PP raw material allows you to use this thread to realize additional possibilities.

Characteristics of polypropylene

- Excellent durability and strength

- Chemical resistance

- Food safe

- Lightweight

- Semi-flexible and tear-resistant

P-filament 721 applications

- Functional parts

- Medical and orthotics

- Products safe for contact with food products

- Part resistant to chemicals and solvents

- Prototyping and modeling

Recommended print settings

- Nozzle temperature: 210 – 230 °C

- Bed temperature: 25 – 80 °C

- Layer height: 0.15 – 0.25 mm

- Print speed: 35 – 70 mm/s

- Cooling fan: On

Features of printing with P-filament 721

- It is recommended to dry the material in PrintDry at 60 – 70°C for 24 hours before 3D printing for better adhesion of the layer and to minimize distortion.

- Preheat: Heat the bed to 90°C for 15 – 20 minutes before printing.

- It is recommended to print in a closed chamber, heating the chamber to 65 – 80 °C.

- To apply the first layer, use a special BuildTak or P-surface 141 printing surface, or Magigoo PP glue.

- For better adhesion to the bed, it is strongly recommended to use edges or a raft.

- Avoid dense and rectangular infill to prevent distortion caused by PP crystallization.

Specifications

| Filament diameter (mm) | 1.75 |

| Material | PP |

| Density (g/cm3) | 0.9 |

| Print temperature (°C) | 210 – 230 |

| Substrate For Printing | BuildTak, P-surface 141, Magigoo PP |

| Heated table | Necessary |

| Table temperature (°C) | 25 – 80 |

| Closed Camera | Recommended |

| Cooling (%) | Included |

| Print speed (mm/s) | 35 – 70 |

| Maximum Chamber Temperature (°C) | 50 – 80 |

| Producing country | China |

| Weight of Plastic (kg) | 0.6 |