- Stock: Out of stock

- Product code: 00-08800347

- Shipping Weight: 1.20kg

Buy PEEK plastic in Ukraine

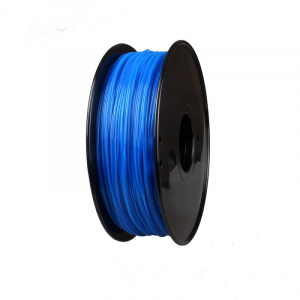

PEEK 3D plastic is currently one of the strongest polymers for 3D printing. Scientifically speaking, it is a semi-crystalline material with a very high melting point. In fact, to work with this plastic, a 3D printer extruder must be heated to over 300°C! Naturally, the material has an extremely high deformation temperature and is suitable for various technical applications. It is for these applications that PEEK plastic is best suited.

In industry, this material is used in the aerospace, automotive, and medical industries. All these areas are also relevant for 3D printing, but when choosing a material, it is worth considering its properties. Our store offers several types of PEEK plastic. This page features a glass fiber reinforced material (70% PEEK, 30% glass fiber). Its detailed characteristics are given in the table below.

Properties and features

- Chemical resistance;

- Very high maximum permissible operating temperature;

- High mechanical strength and rigidity;

- Wear resistance;

- High creep resistance;

- Resistance to gamma and X-ray radiation;

- Low flammability and smoke emission when burned.

Technical specifications

| Characteristic | Standard | Value |

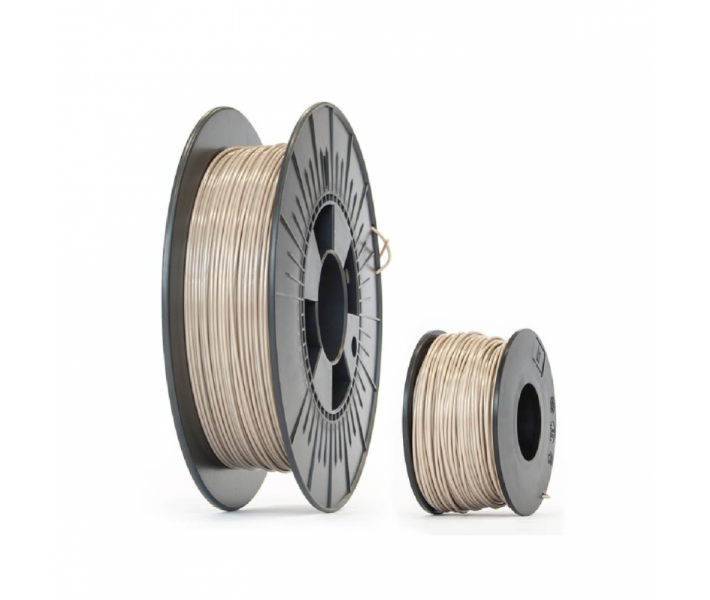

| Color | Natural or black | |

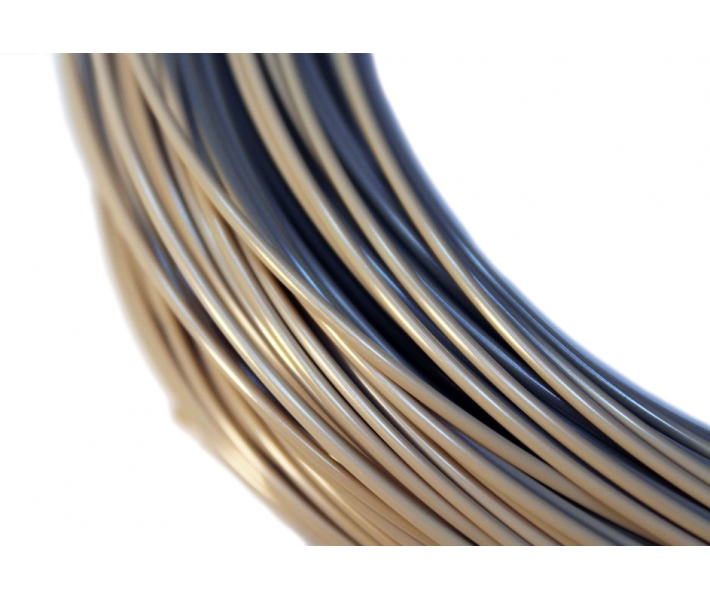

| Thread diameter | 1,75 mm | |

| Density | ISO 1183 | 1,5±0,01 g/cm3 |

| Solubility in water (for 24 hours at 25˚С) | ISO 62 | 0,11% |

| Shrinkage percentage | 3 мм, 170˚С, flow direction | 0,4% |

| Perpendicular to the direction of flow | 0,8% | |

| Melting point | DSC | 343 ˚С |

| Distortion temperature | ASTM D648 | 315 ˚С |

| Continuous use temperature | UL 74685 | 260 ˚С |

| Coefficient of thermal expansion | ASTM D696 | 2,2*10-5 ℃ |

| Tensile strength (at 23 ˚C) | ISO527-2/1B/50 | 155 MPa |

| Relative elongation (at 23 ˚C) | ISO527-2/1B/50 | 2% |

| Bending strength (at 23 ˚C) | ISO 178 | 212 MPa |

| Compressive strength (at 23 ˚C) | ASTM D695 | 215 MPa |

| Izod impact strength (unnotched) | ISO 180/U | 51 |

| Rockwell hardness | ASTM D785 | 103 |

| Flammability Rating | UL 94 | 1,5 V-0 @mm |

| Dielectric strength | IEC 248 | 1,9 kV/m |

| Dielectric constant | IEC 250 | 3,3 |

| Surface resistance | 1015 Om | |

| Friction coefficient | 0,38-0,46 μ | |

| Coil weight | 1 kg |