- Stock: In Stock

- Product code: 00-08800035

- SKU: PKG-WS-FS1-P-30-230V

Available Options

- Description

- Characteristics

- Compare Printers

- Fuse Complete Service Plan

- Choose Fuse 1+ Package

- Compatibility

- Fuse 1 3D Tour

- Reviews

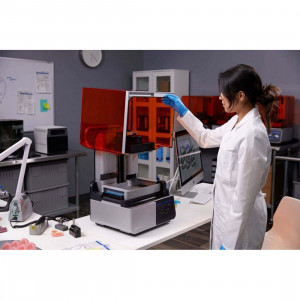

SLS 3D Printer Formlabs Fuse 1+ 30W

Successful launched Fuse 1 compact SLS 3D printing system, Formlabs continues to develop hardware and introduce their new Fuse 1+ 30W 3D printer.

The new Fuse 1+ system creates mechanically improved Nylon parts twice faster than Fuse 1 and allows you to achieve Zero Waste in your production.

Fuse 1+ 30W is the highest performance, affordability and savings you can get from SLS 3D printing on the market.

Build Volume: 165 × 165 × 300 mm

Fuse 1+ SLS printing system 2x faster

What are the main features of the new Fuse 1+ 30W?

- The Fuse 1+ printer prints twice as fast as the previous version of the printer – thanks to a powerful 30-watt laser and an improved galvanometer system.

- The Fuse 1+ has an upgraded powder handling system. Thanks to this, printing with new exclusive materials is available to him.

- Nitrogen inert gas printing makes it possible to print parts from existing and new materials with improved mechanical properties.

- In addition, printing in an inert gas environment and denser packing of parts in the print volume provide significant material savings.

Fuse 1+ 30W: profitable SLS printing

The Fuse 1+ 3D printer system makes SLS printing truly affordable, fast and cost-effective:

- The low cost of a 3D printer compared to competitors.

- Affordable materials.

- Increased print speed: with PreForm 3.34.0 – 25% faster than the previous software and 3 times faster than Fuse 1. From an idea to a ready-to-use industrial-quality functional part, it takes a matter of hours.

- Improved parts packing density in a single print.

- Enlarged powder recyclability – zero waste printing, enabling lower cost per part.

Zero Waste SLS Printing with Formlabs

Formlabs have added the ability to print in an inert gas environment to their new Fuse 1+.

The first consequence of this innovation is the improved mechanical properties of printed models. Nitrogen injected into the print chamber displaces oxygen from the print chamber. So you got sintered parts that are less brittle and more ductile, making them more suitable as end-use components, especially in harsh environments such as the automotive or aerospace industry. Compatible nitrogen generators are widely available for purchase, and recommended models can be found. To choose one talk to a member of our store sales team.

The second is practically waste-free SLS printing. The inert oxygen-free atmosphere provides a more efficient sintering process for Nylon 11 Powder and Nylon 11 CF Powder by protecting the green powder from oxidation. Unoxidized powder can be reused in the next printing cycle. This results in a higher powder recyclability. Combined with an optimal packing density, can create a waste-free printing workflow. Without an inert gas atmosphere, Nylon 11 and Nylon 11 CF Powders have a 50% refresh rate, which means that 50% recycled and 50% fresh powder must be used to create each new cartridge. In a nitrogen environment, this improves up to 30% for both materials.

Fuse 1+ 30W Printer Package

- 3D printer Fuse 1+ 30W (including Fuse Build Chamber)

- Formlabs PreForm Software

- Fuse Series Complete Service 1 Year*

* You can also select Fuse Series Complete Service Plan for 3 or 5 year.

Specifications

| Fuse 1 | Fuse 1+ 30W | |

| Technology | Selective Laser Sintering | Selective Laser Sintering |

| Build Volume (W x D x H) | 165 × 165 × 300 mm | 165 × 165 × 300 mm |

| Layer Thickness | 110 mcm | 110 mcm |

| Build Speed (20% packing density) |

0.3 liter per hour | 0.5 liter per hour With PreForm 3.34.0 – 25% faster than the previous software and 3 times faster than Fuse 1. |

| Material Refresh Rate | 30–50 % | 30–50 % |

| Hopper Capacity | 17,8 L | 14,5 L |

| Supports | No supports | No supports |

| Startup Time | < 60 minutes | < 60 minutes |

| Internal Temperature | 200 ºC | 200 ºC |

| Laser Type | Ytterbium Fiber | Ytterbium Fiber |

| Laser Spot Size (FLSW) | 200 mcm | 247 mcm |

| Laser Specifications | IEC 60825-1:2014 certified 1070 nm wavelength Maximum 10 Watts 4.01 mrad beam divergence (nominal, full angle) |

Ytterbium Fiber IEC 60825-1: 2014 certified 1070 nm wavelength Maximum 30 Watts 3.24 mrad beam divergence (nominal, full angle) |

| Radiation Information | The Fuse 1 is a Class 1 Laser product. Accessible radiation is within Class 1 limits. | The Fuse 1 is a Class 1 Laser product. Accessible radiation is within Class 1 limits |

| Temperature Control | Quartz tube heating elements Positive temperature coefficient (PTC) cartridges |

Quartz Tube Heating Elements Resistive Air Heater |

| Air Handling | Pressure-controlled two-stage filtration (Replaceable HEPA and carbon mediums) |

Interface to external inert gas supply Pressure controlled two-stage filtration (Replaceable HEPA and carbon mediums) |

| Galvanometers | Formlabs Custom | Formlabs Custom 2nd Generation |

| Printer Control | 10.1” interactive touchscreen 1280 × 800 resolution |

10.1” interactive touchscreen 1280 × 800 resolution |

| Notifications | Touchscreen alerts and tracking SMS/email via Dashboard Live video feed with computer vision Proactive maintenance alerts |

Touchscreen alerts and tracking SMS/email via Dashboard Live video feed with computer vision Proactive maintenance alerts |

| Print Preparation | PreForm Desktop Software | PreForm Desktop Software |

| File Types | .STL or .OBJ • FORM file output |

.STL or .OBJ • FORM file output |

| Connectivity | Wi-Fi (2.4 GHz) Ethernet (1000 Mbit) USB 2.0 |

Wi-Fi (2.4 GHz) Ethernet (1000 Mbit) USB 2.0 |

| System Requirements | Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended) |

Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended) |

| Power Requirements | EU: 230 VAC, 7.5 A (dedicated circuit) | EU: 230 VAC, 7.5 A (dedicated circuit) |

| Printer Dimensions(W × D × H) | 645 × 685 × 1070 mm (1655 mm with stand) | 645 × 685 × 1070 mm (1655 mm with stand) |

| Minimum Access Dimensions (W × D × H) | 1255 × 1495 × 1870 mm | 1255 × 1495 × 1870 mm |

| Weight | 114 kg (without build chamber or powder) | 120 kg (without build chamber or powder) |

| Operating conditions | 18 – 28 ºC. ≤ 50% ambient humidity | 18 – 28 ºC. ≤ 50% ambient humidity |

| Warranty | 1 year | 1 year |

Formlabs Fuse 1+. Buy in Ukraine

Printing from Nylon 11 on the new Formlabs Fuse 1+ 30W printer

The new Formlabs Fuse 1+ 30W SLS printer can use up to 70% refreshed Nylon 11 Powder:

Downloads

Fuse 1+ 30W | Fuse 1 |

High-Perfomance Benchtop SLS 3D Printer | Accessible Benchtop SLS 3D Printer |

Laser Type 30 Watt Fiber LaserUnlocks Same-Day, In-House 3D Printing | Laser Type 10 Watt Fiber LaserUnlocks Reliable, In-House 3D Printing |

Material Compatibility Eight MaterialsNylon 12, Nylon 12 White, Nylon 12 Tough, Nylon 11, Nylon 12 GF, Nylon 11 CF, Polypropylene and TPU 90A Powders | Material Compatibility Four MaterialsNylon 11, Nylon 12, Nylon 12 GF and TPU 90A Powders |

Print Environment Options Inert Gas and AirInert Gas Enhances Material Properties and Recyclability | Print Environment Options AirOne Option. Easy Setup. |

Efficiency Zero Waste PrintingEnabled by High Print Density and Material Recyclability | Efficiency Low Waste PrintingEnabled by High Print Density |

Throughput 2X Faster for Same-Day Part DeliveryTypical print jobs complete in 7 hours and 95% of fully packed print jobs can be completed in 14 hours | Throughput Next-Day Part DeliveryDeliver parts <24 hours |

Fuse Series Complete Service Plan Benefits

The Fuse Series Complete Service Plan is designed for maximum peace of mind with private remote training to get you started, direct phone and email support, as well as preventative checkups to keep you printing, and rapid repairs by Certified SLS Experts to resolve any major issues.

| Coverage | Each Plan includes support for one Fuse Series printer, one Fuse Sift and one Fuse Blast |

| Warranty | One, two, three or five years |

| Printer/Component Replacement | ✔ |

| Direct Phone Supoport | ✔ Mon - Fri, 9 am - 6 pm ET and CET. Multilingual support in English, German, French and Italian. |

| Annual Preventable Checkups | ✔ An annual onsite visit from a trained expert to perform routine maintenance. |

| Training Videos & Live Q&A | ✔ Schedule a live session with a Pro Service Expert to ask questions about your specific workflow. |

| Onsite Repairs | ✔ |

| Fleet Pricing | ✔ Discounts available for co-located printers |

Eliminate the Unexpected

Maximize your return, protect your investment, and eliminate unexpected costs with our service plan for Fuse Series SLS 3D printers, Fuse Sift, and Fuse Blast.

Worry-free warranty coverage and repairs

Our team will work with you to quickly resolve any issues through remote support, including shipping replacement parts free of charge. If we determine that an onsite visit is necessary, Formlabs or your certified local partner will send a Certified SLS Expert to your facility at no extra charge.

Up to five years of coverage for your entire fleet

The Fuse Series Complete Service Plan offers one, two, three, or five years of support that can be renewed at your discretion. Purchase more years upfront for additional savings.

Priority phone and email support

Priority phone and email access to our team of dedicated experts.

Annual preventative checkups

Get an annual onsite visit from a trained expert to perform routine maintenance so you can stay focused on running your business.

Training videos and a live Q&A

Watch our onboarding videos to get started and schedule a live Q&A with one of our experts to answer any questions about your workflow or applications.

Onsite training available to purchase

Get to know your printer and post-processing on your home turf with a customized training session defined by your needs, enabling you and your team to become SLS experts in no time.

Terms and conditions apply. Please see the Formlabs Fuse Series Service Plan Terms of Service for more information.

Build Your Own Package |

Starter Package |

Complete Package |

High Efficiency Package |

|

| Fuse 1+ 30W Printer 230V (including Build Chamber) | ✔ | ✔ | ✔ | ✔ |

| Fuse Build Chamber 230V | ✔ | ✔ | ||

| Fuse Powder Cartridge | ✔ | 2 ✔ | 2 ✔ | |

| Fuse Depowdering Kit Workspace and Tools | ✔ | |||

| Fuse Depowdering Kit Sifter (230V) with 150 Sieve | ✔ | |||

| Fuse Series Printer Stand | ✔ | ✔ | ||

| Fuse Sift 230V | ✔ | ✔ | ||

| Fuse Blast | ✔ | ✔ | ||

| Fuse Blast Polishing Module | ✔ | |||

| Fuse Blast Polishing Media 4 L (2.5 kg) | 2 ✔ | |||

| Fuse Blast Polishing Agent 115 mL | ✔ | |||

| Fuse Blast Polishing Mesh | ✔ | |||

| Nylon 12 Powder 10 kg | 4 ✔ | |||

| Industrial Vacuum 230V | ✔ | |||

| PreForm Software | ✔ | ✔ | ✔ | ✔ |

| Fuse Series Complete Service Plan for 1 year | ✔ | ✔ | ✔ | ✔ |

| Fuse Series Complete Service Plan* for 3 or 5 years | Optional | Optional | Optional | Optional |

* Maximize your return, protect your investment, and eliminate unexpected costs with Formlabs Fuse 1+ 30W and

Fuse Sift Service Plans.

Maximum peace of mind with Fuse Series Complete Service Plan

The Fuse Series Complete Service Plan is designed for maximum peace of mind with private remote training to get you started, direct phone and email support, as well as preventative checkups to keep you printing, and rapid repairs by Certified SLS Experts to resolve any major issues.

- Worry-free warranty coverage and repairs

- Up to five years of coverage for your entire fleet

- Priority phone and email support

- Annual preventative checkups

- Training videos and a live Q&A

- Onsite training available to purchase

Fuse 1 | Fuse 1+ 30W | |

Nylon 11 | ✔ | ✔ |

Nylon 11 CF | ✔ | |

Nylon 12 | ✔ | ✔ |

Nylon 12 White | ✔ | |

Nylon 12 Tough | ✔ | |

Nylon 12 GF | ✔ | ✔ |

TPU 90A | ✔ | ✔ |

Polypropylene | ✔ |