- Stock: In Stock

- Product code: 00-00000088

- Shipping Weight: 21.00kg

- SKU: PKG-F3B-WS-BASIC

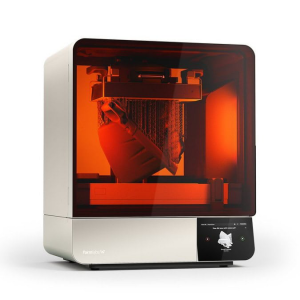

3D printer Formlabs Form 3B+

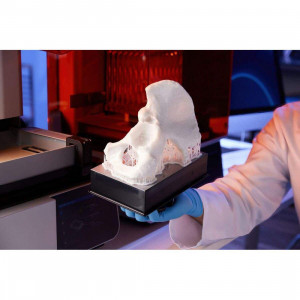

3D printer Formlabs Form 3B is a novelty from FORMLABS specially designed for Dentistry and Medicine. It is specially designed for 3D printing with biocompatible materials.

Form 3B benefits

New technology of industrial 3D printing

Formlabs has developed a new stereolithography technology – LFS Low Force Stereolithography. The peculiarities of the LFS technology are that by reducing the intensity of illumination, it is possible to achieve clarity of details and incredible smoothness of the surface. Additional painstaking post-processing is no longer required for such products.

Precision is the quality of 3D Printing (Точность – качество 3D печати)

LPU is a newly developed light unit inside 3D printer that uses a compact system of mirrors and lenses to produce super-precise printed products.

High speed

The high frequency galvanometer provides high speed and precise control.

Large build field area

With a large print area of 145 * 145 * 185(193) mm, the Form 3B will be able to produce more items in a single print than DLP printers with a smaller print area. This way you can save time – on model preparation, printer maintenance and printing itself. On average, Form 3B saves you up to 55% labor savings than DLP printers.

FORM -3B is compatible with other Formlabs 3d printers and equipment. If you wish, you can create a production line that is consistent and well-coordinated.

Easy material change

Switching between materials is completely problem-free, thanks to a simple cartridge system, the switching process takes a few seconds.

Uniform 3D printing (Равномерная 3D-печать)

The parabolic mirror guarantees that the laser prints perpendicular to the build plane, ensuring consistent print quality across the entire platform.

Convenient post processing

Form Cure and Form Wash produce perfectly finished products with minimal cost.

Especially for Dentistry and Medicine

Formlabs Form 3B is capable of printing products for several dental areas, and for each of them it has been thoroughly tested by a team of professionals from Formlabs. Materials suitable for every available area are produced in convenient cartridges that are easy to change.

Embedded software

Thanks to Form 3B, you do not need to deal with detailed processing of the model and waiting for 3D printing. The built-in software PreForm will automatically prepare a model from a CAD file for printing and select the necessary 3D printing settings.

Convenient collaboration

Multiple people can work with the printer at the same time by submitting models for printing through PreForm, so you can manage all your Formlabs printers and groups through the online dashboard.

Digital dentistry workflow examples

Formlabs Form 3B Specifications

| Technology | Low Force Stereolithography (LFS)™ |

| Printing material | Photopolymer resins |

| Software | FORMLABS PREFORM |

| Laser Spot Size | 85 microns |

| Laser Specifications | 1 Light Processing Unit EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron laser spot |

| Operating Temperature | Auto-heats to 35 °C |

| Temperature Control | Air-heated print chamber |

| Build Volume (W x D x H) | 145×145×185 mm (193 mm with PreForm 3.34.0) |

| XY Resolution | 25 microns |

| Layer Thickness (Axis Resolution) | 25 – 300 microns |

| Printer Control | 5.5″ interactive touchscreen 1280 × 720 resolution |

| File Types | STL and OBJ file input FORM file output |

| System Requirements | Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM |

| Connectivity | Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

| Power Requirements | 100–240 VAC, 2.5 A, 50/60 Hz, 220 W |

| Printer Dimensions (W × D × H) | 405×375×530 mm |

| Weight | 17.5 kg |

| Application area | Design; Architecture; Packaging; Advertising; Medicine; Souvenir industry; Jewelry making; Education; Dentistry; Production |

Form 3B+ Basic Wholesale Package includes:

- Form 3B+ 3D printer

- Bath for resin F3 Resin Tank V2.1

- F3 Build Platform 2

- F3 Finish Kit

- Form Wash

- PreForm software

- Warranty – 1 year

Form 3+ |

Form 3B+ |

|||||

Basic |

Complete |

Automation |

Basic |

Gold |

Automation |

|

| 3D Printer |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

| F3 Resin Tank |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

| F3 Build Platform |

✔ |

|||||

| Build Platform 2 |

✔ | ✔ |

✔ |

✔ |

✔ |

|

| F3 Finish Kit |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

| Form Wash V1 |

✔ | ✔ |

✔ | ✔ |

||

| Form Cure V1 |

✔ |

✔ |

||||

| Form Auto |

✔ |

✔ |

||||

| PreForm |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

| 1 Year Basic Warranty |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

| Pro Service Plan: 1, 2 or 3 Years | Optional | Optional | Optional | |||

| Dental and Medical Service Plan: 1, 2 or 3 Years | Optional | Optional | Optional | |||

Medical Service Plan (MSP)

Available for Form 3B+, Form 3BL and Form 4B, Form 4BL. Available in North America and EMEA only.

Compare Benefits

All Formlabs hardware comes with a basic one-year limited warranty, phone and email support. Purchase a Medical Professional Service Plan to extend your coverage further and also get all these great benefits.

| Basic Warranty |

Medical Service Plan |

|

| Duration | 1 year |

Up to 5 years |

| Printer/Component Replacement |

✔ |

✔ |

| Hot Swap |

✔ If troubleshooting doesn't get you back to printing, we'll expedite a replacement. |

|

| Chat & Email Support |

✔ |

✔ |

| Phone Support |

✔ Mon - Fri 9 am - 6 pm ET and CET. Phone support by our team. Multilingual support in English, German, Italian, French. |

✔ Mon - Fri 9 am - 6 pm ET and CET. Priority phone support by our team of dedicated experts. Multilingual support in English, German, Italian, French. |

| Training |

✔ Training Videos |

✔ Training Videos & Live Q&A Schedule a live session with a Certified Medical Agent to ask questions about your specific workflow. |

Premium 3D Printing Support, Made for Medical Professionals

Your business needs a 3D printing solution you can rely on for nonstop production. Behind our Medical Service Plan is a dedicated team of certified medical 3D printing specialists who know exactly how to support your healthcare facility.

Basic Warranty

Our included warranty provides peace of mind and access to support resources

- One-year warranty

- Printer/Component Replacement

- Chat & Email Support

- On-demand resources through Formlabs support site

Medical Service Plans

Consultations from Medical Experts

Schedule a consultation with a trained and certified expert in regulatory affairs and quality assurance.

Priority phone and email support

Priority phone and email access to our team of dedicated experts.

Training videos and a live Q&A

Watch our onboarding videos to get started and schedule a live Q&A with one of our experts to answer any questions about your workflow or applications.

Hot swap expedited printer replacement

Ensure constant uptime: Formlabs will ship you a replacement printer to keep you printing if your printer needs to be repaired or replaced.

Warranty for the duration of the plan

The Medical Professional Service Plan extends the one-year warranty included with your printer to the full duration of the chosen plan.

Terms and conditions apply. Please see the Formlabs Medical Service Plan Terms of Service for more information.