Description

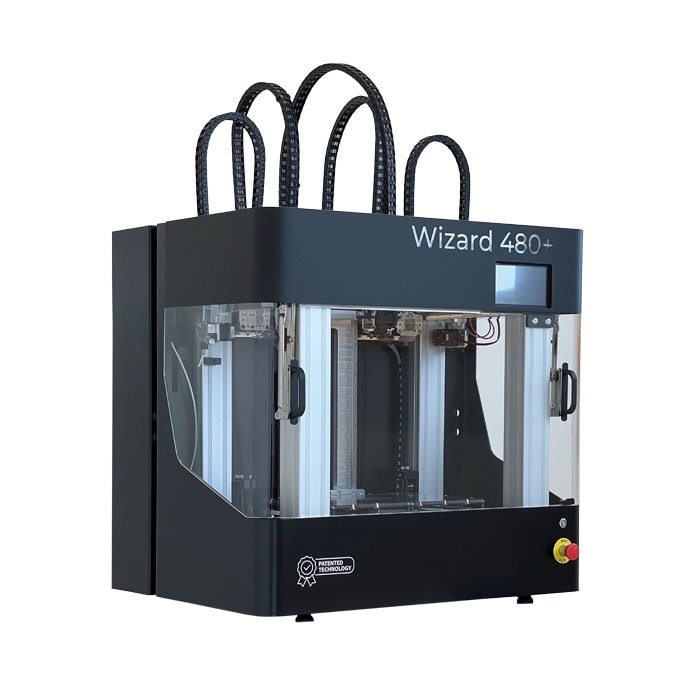

The next generation of 3D printers – Wizard 480+

We are pleased to introduce the Wizard 480+, an advanced modular 3D printer that is capable of printing any type of filament available on the market.

A unique printer with an open modular system. One machine prints and performs the functionality of different printers with a maximum variety of materials.

With 4 automatic interchangeable printheads and 3 to 5 axis technology, Wizard printers become truly multi-tasking and capable of producing the most complex parts. This advanced technology enables the creation of 3D printed parts from continuous carbon fibers that are extremely lightweight yet highly durable.

Main features

- Modular design – Expands the range of applications available.

- Printheads – 4 automatic Direct/Bowden interchangeable printheads, quick change in less than 3 seconds.

- Large print volume – 400*250*370 mm.

- Nozzle temperature – up to 500 °C.

- Repeatable print accuracy – up to 0.02 mm.

- Open system – free choice of filament and slicer. Simplification of the 3D standard, choice of data storage – locally or in the cloud.

- Axial technology – 3 axes.

- Print heads water cooling.

- Built-in patented cutting system in the print head.

- Heating of the working surface – up to 200°C.

- Video surveillance.

Available printing technologies

Unique features make the Wizard 480+ the most innovative and versatile 3D printer in the world, as it is capable of printing with many FDM technologies:

- FFF printing technology – production from fused filaments.

- CFF technology – production from continuous filament.

- Sinter technology – sintered materials.

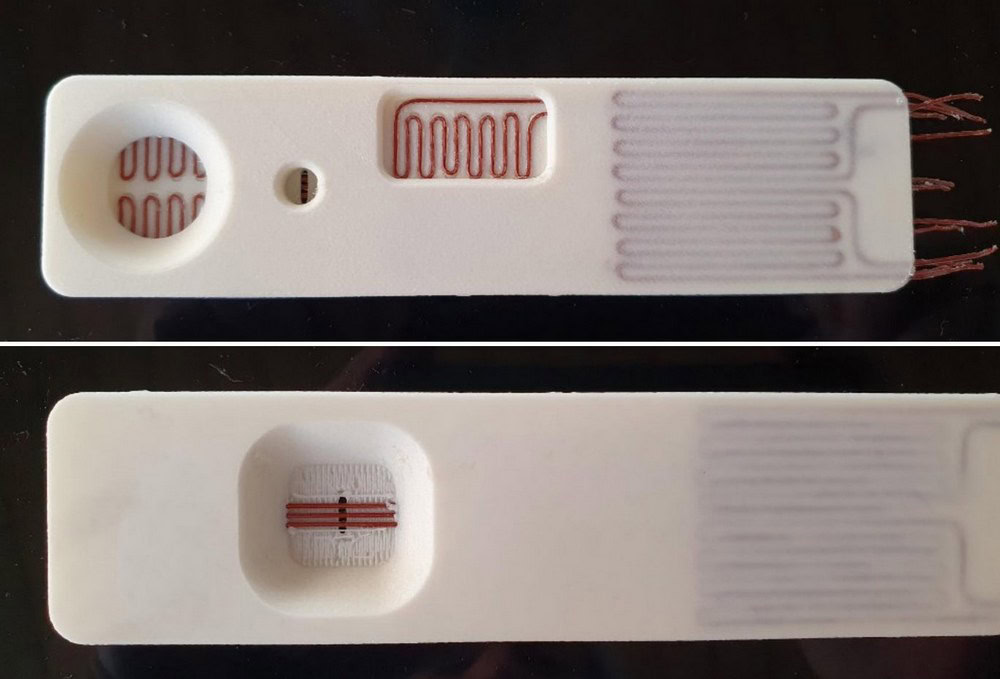

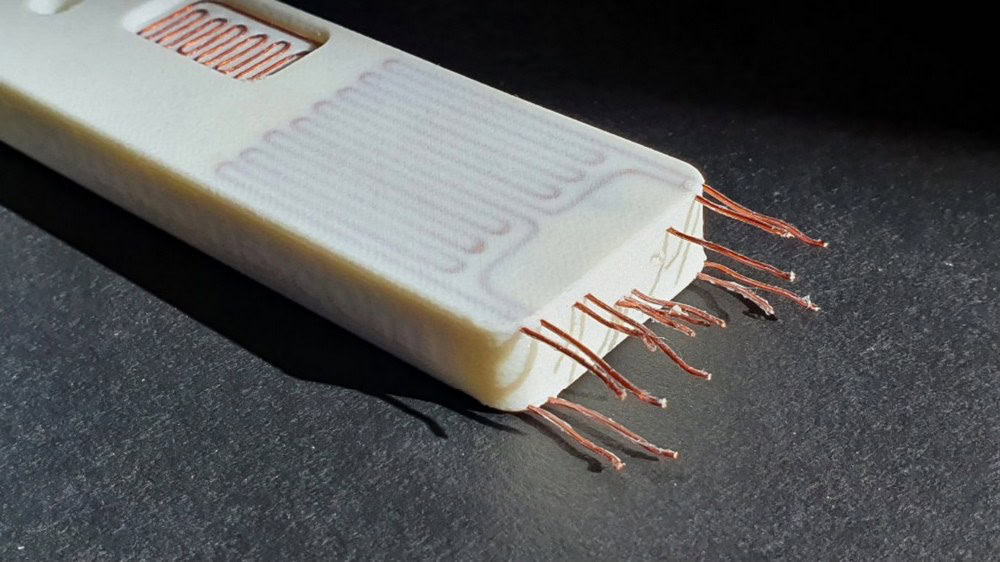

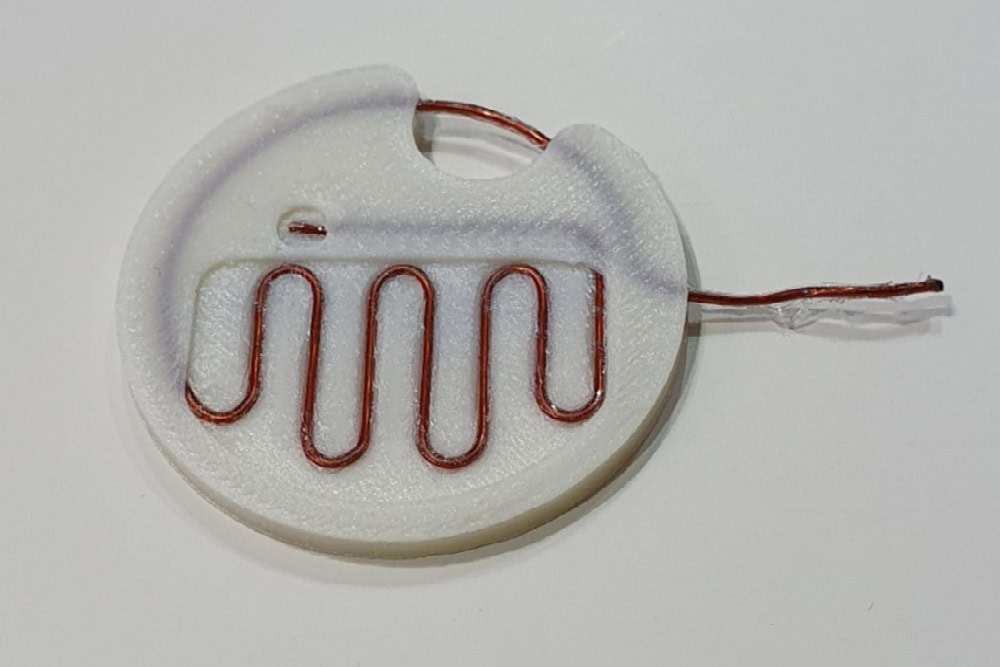

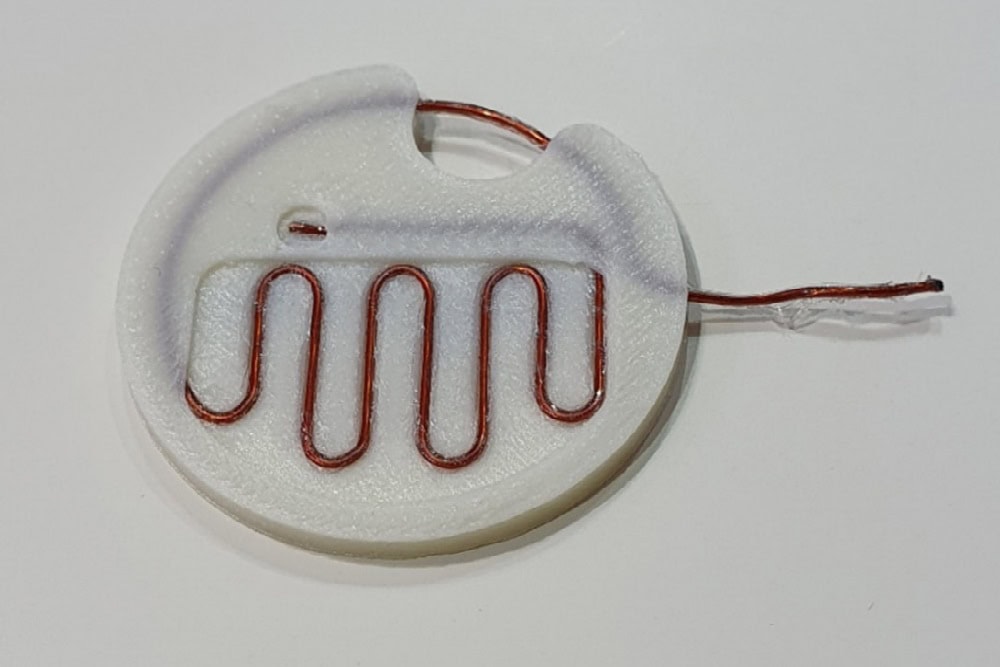

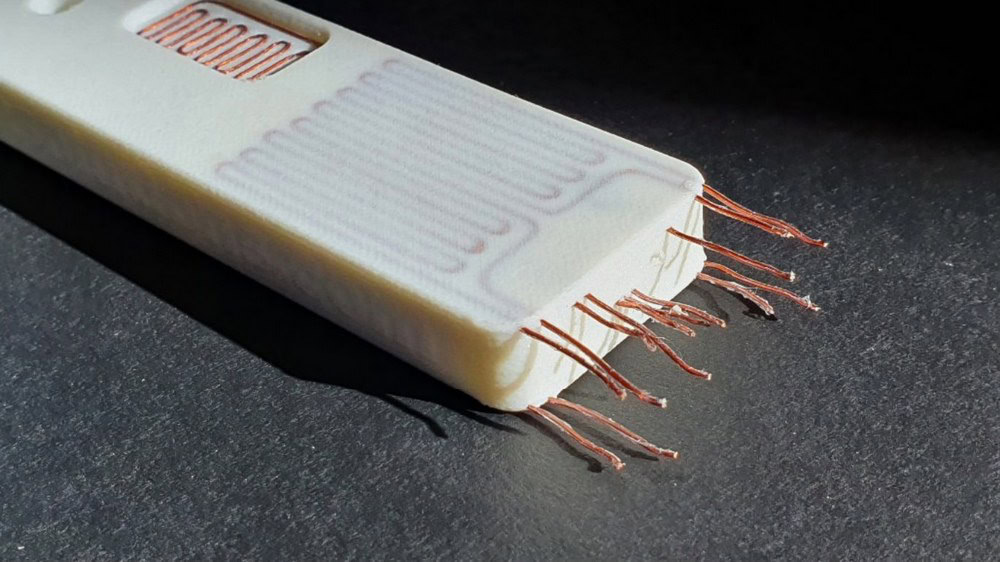

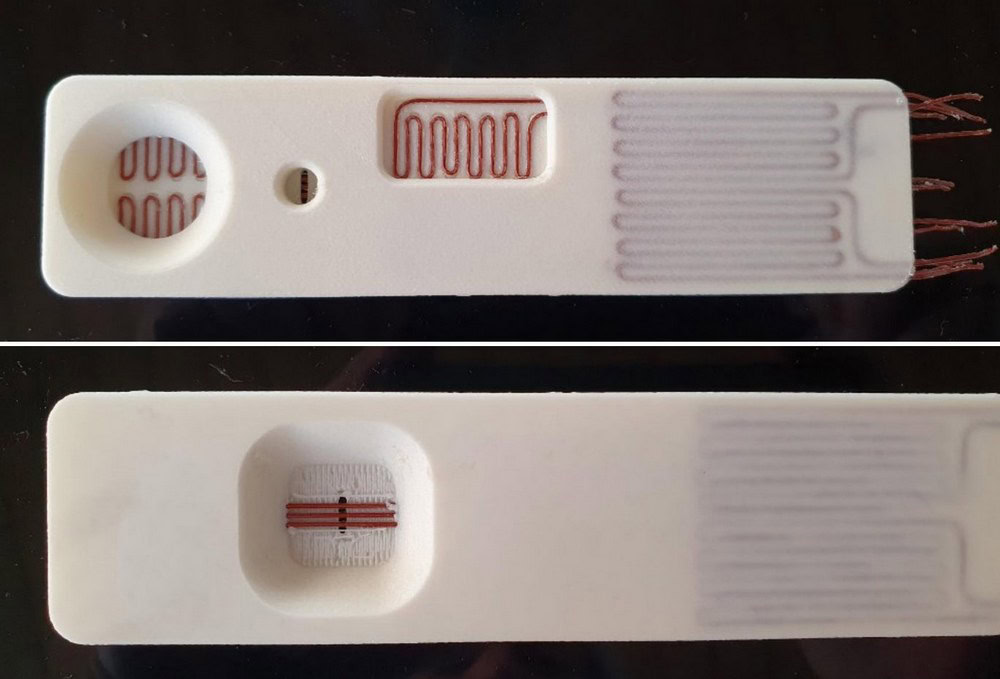

- Greenling technology – copper wires and optical fibers, etc. in the matrix.

New possibilities with additional modules for Wizard

Adapt the system to your needs: upgraded printheads, heating chamber, air filter, etc. Customized solutions with specific requirements are one of the printer’s strengths.

As a versatile 3D printer, the Wizard 480+ can also be customized with modules such as laser functions, processing, assembly, transportation, and more. For example, modules such as RFID or sensors can be integrated directly into the 3D printed part. These features open up a wide range of application possibilities that were not previously possible.

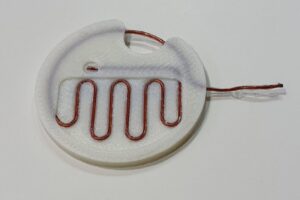

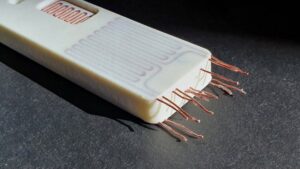

Samples of 3D printed copper wires with the WIZARD 480+

Open system

Modular 3D printer Wizard 480+ creates no restrictions for third-party suppliers. Open hardware and software add benefits such as free choice of printing materials, and even 3D printing technologies and more:

- Free choice of filaments.

- Continuous carbon fiber printing.

- Print continuous fibers directly on the garage work surface.

- Patented print head with integrated cutter.

- 4 automatic changeable printheads.

- Optional modules that can be selected and customized.

Custom high-tech filaments from APS are also available upon request.

Unlimited choice of materials

The standard WIZARD printer series covers a large number of materials – from standard plastics to high-performance materials with continuous carbon fibers or integrated metal filament printing in the die to optical fibers.

- FFF – ABS, CPE, PET, PC, PLA, PVA, Nylon, PEI, PEEK, PEKK, PA carbon fibers.

- CFF – Carbon Fiber, Glass Fiber, Aramid, 1.5k (1-3k on request).

- Sinter – 316L, 17-4PH, 1.2709, IN 718, IN 625, Ti, Ti6AI4V, Wco, ZrO2, AlO3.

- Copper wires and optical fibers, etc. in the matrix, additional materials on request.

| Connecting rod PEKK + continuous carbon fiber Continuous fiber-reinforced connecting rod for heavy-duty applications. The component coating is printed with filament: 100% PEKK and the load bearing with filament: 55% continuous carbon fiber with 45% PEKK matrix. |

| Gaiter TPU Thermoplastic polyurethane PEKK + endless carbon fiber vacuum suction cups for part handling in robot systems. |

| Component for flying drone PA polyamide and copper wire Copper wire motor supply lines integrated in drone arm (open). |

| Connecting rod 316L stainless steel 1.4301 3D printing of stainless steel component, printed using powder-bonded filament (sintered component). |

| Case for wristwatch Ceramic Al2O3 sintered 3D printing of ceramic component, printed using powder-bonded filament, Al2O3 aluminum oxide (view: sintered, ground and polished component). |

| Wing rib 55% carbon 3D printing with pure continuous fiber using the CFF process (without PEKK component coating). To enable maximum load-bearing capacity, the wing rib is made entirely of Filament: 55% continuous carbon fiber with 45% PEKK matrix. |

| Turbine wheel 316L stainless steel 1.4301 3D printing of stainless steel component, printed using powder-bonded filament (sintered component). |

| Squeeze-out tool PA polyamide + carbon Fast and simple production of assembly aids. |

Continuous Filament Manufacturing (CFF)

Produce high-strength and lightweight parts from solid carbon fiber. Enhance your details with other continuous filaments such as fiberglass, aramid, metal wires and more.

For large components

Using the standard Wizard 480+, you can manufacture components up to 400*250*370 mm in size.

Multiple print heads

The printer can use up to 4 different materials or material variants at the same time.

High temperature printing with water cooling of the head

Water-cooled print heads ensure precision, repeatability and absolute accuracy. Thanks to the advanced FFF technology, it reaches temperatures up to 500 °C, which enables the processing of high-performance polymers.

Unrivaled accuracy

A high-precision gantry design with powerful drives, combined with our many years of experience in custom design and robotics, has resulted in a high-precision additive manufacturing machine for complex industrial requirements.

Made in Europe

Conceived, developed and assembled in Austria with APS (Automatisierte Produktions-Systeme Gesellschaft m.b.H.) in-house precision and highest quality. 90% of all components are manufactured in Europe/EU.

Wizard 480+ modular 3D printer – specifications

| 3D printing technology | FDM |

| Print volume with two fixed print heads | 400*300*400 |

| Print volume with automatic print head change | 400*255*370 |

| Print volume | 48 л |

| Frame construction | High precision and stable gantry design |

| Construction of the z-axis | High precision spindle |

| Printhead speed | Max. 500 mm/sec. |

| Automatic printhead change system | 4 slots (1 slot = 1 printhead) |

| Tool change time | <3 sec |

| Printhead actuator | Direct drive / Bowden drive. Heavy-duty stepper motor with control system |

| Print head | Automatic nozzle lift function, single nozzle, with integrated in-line cutter |

| Printing temperature | Up to 500 °C |

| FFF nozzle diameter | 0.15 – 1.2 mm |

| FFF thread diameter | 1.75 / 2.85 mm |

| CFF nozzle diameter | 0.6 – 1.2 mm |

| CFF filament diameter | 1 – 3 k |

| Layer thickness | Min. 0.03 mm depending on the material |

| Head temperature | Up to 200 °C |

| Print surface alignment | Controlled by a sensor |

| Print speed | Up to 24 mm³/s 10-40 mm/s |

| Filament control | Automatic |

| Extruder cooling | Water cooling system |

| Electrical functions | Pause and restart function, power failure – restart function |

| Controls | 7” touch screen display |

| Body size | 1000*800*1500/2000 mm |

| Weight | 120 kg |

| X-axis repeat accuracy | Up to 0.02 mm, depending on process speed |

| Y-axis repeatability up to 0.02 mm, depending on process speed | Up to 0.02 mm, depending on process speed |

| Z-axis repeat accuracy | Up to 0.02 mm |

| Additional modules | |

| Heated print chamber | Thermal separation of drive and guide unit, up to 70°C |

| Print chamber | Exhaust filter |

| Filament storage | Straight / Bowden drive (depending on the type of filament). Max. 4 active |

| Replaceable print heads | Max. 4 automatically changing printheads (only one extruder in motion) |

| Replaceable tool holder | Max. 4 automatically changing holders (only one holder in motion) |

| Optical control | Webcam |

| Remote maintenance | Via the Internet (Team Viewer) |

| Continuous Filament Fabrication (CFF) | |

| CFF – continuous filaments | – Carbon fiber, glass fiber, aramid, … |

| – Thickness: 1.5k (on request 1k or 3k) | |

| – Matrix: PA6 (on request: PEKK, PEEK, PLA, … ) | |

| CFF – special filaments | copper -, tungsten -, metal wire, optical fiber etc. |

| Fused Filament Fabrication FFF | |

| FFF – plastic plastics | ABS, CPE, PET, PC, PLA, PVA, TPU, Nylon тощо |

| FFF – high-perfomance plastics | PEl, PEEK, PEKK, Carbon Fiber PA тощо |

| FFF for sinter applications | |

| High alloy chromium steels | 316L | 1.4404, 17-4PH | 1.4542 |

| Martensitic steel | 12.709 |

| Superalloys | IN 718 | 2.4668, IN 625 | 2.4856 |

| Light metals | Ti | Titanium (unalloyed), Ti6Al4V | 3.7165 |

| Hard metals | WCo in various mixing ratios on request |

| Ceramics | ZrO2, AlO3 |

| Additional tools | |

| Print head | Double nozzle |

| Special tools | E.g. milling head, laser for marking, integration tool for nuts, bolts, RFID, etc. |

| Software | |

| Software | Slicer Simplify 3D (included with standard filament) |

| Plugin for Simplify 3D | Included with continious print head |

| Operating system | Windows 10 Apple, Linux, Android |

| File types | .stl (other files need to be converted to .stl) |

| Print commands | G CODE |

| Interfaces | WIFI, USB, Ethernet |

| Electrical installation | |

| Electric power | 230 V (50 Hz) 16 A |

| Input power | 300-400 W maximum 2500 W |

| Country of manufacture | Austria |

Reviews

There are no reviews yet.