- Stock: In Stock

- Product code: 00-00012113

- Shipping Weight: 2.00kg

- SKU: F4-RPS-01

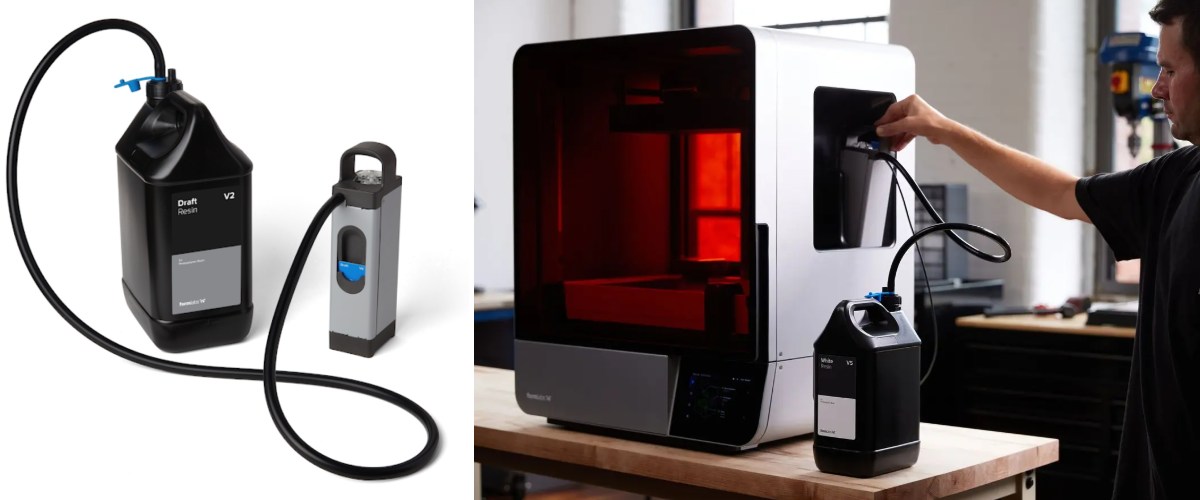

Resin Pump 3D Printer Resin Supply System for Form 4

Resin Pump 3D Printer Resin Supply System for Form 4 is designed to work with the Form 4 3D printer. The device automates and simplifies the process of supplying photopolymer resin. The pump optimizes SLA/LFS printing procedures by ensuring a uniform and uninterrupted filling of the reservoir with resin. This reduces the time spent on preparing and maintaining the printer.

Key benefits of Resin Pump

- Automate the supply of printing resin. The device eliminates the need for manual refilling, reducing

the likelihood of errors and contamination of the material.

- Precise flow control. Uniform supply ensures consistent print quality, even for long or complex

projects.

- Save time. Resin Pump speeds up the preparation stages, allowing you to focus on the work, not on

equipment maintenance.

- Easy to use. Quick installation and full compatibility with the Form 4 series make the device an

indispensable addition to 3D printers.

- Reduced waste. Precise dosing allows you to save material. The volume of waste is reduced by up to 86%, and the operating costs of resin 3D printing are reduced by about 20%.

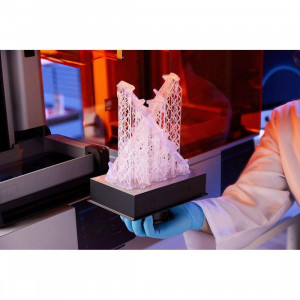

3D printing with resin: areas of application of Resin Pump

Resin Pump for Form 4 is widely used in professional areas:

- Engineering and prototyping. Creation of detailed and functional models.

- Jewelry production. Printing of complex and miniature products.

- Dentistry. Manufacturing of precise medical models and devices.

- Decorative art. Working with elements of complex geometry.

The structure and principle of operation of Resin Pump

The resin supply system consists of two key elements:

- Resin pump – replaces the standard liter cartridge, installed in the back or side of the printer.

- External container with a capacity of 5 liters – includes a resin card, which transmits information about the type of material to the printer, ensuring the correct operation of the entire system.

Is it possible to refuse to use Resin Pump?

Technically, it is possible, but it is associated with a number of inconveniences:

- Manual addition of resin requires constant attention and can lead to errors, such as overflow or lack of

material.

- The risk of contamination of the working area increases, which affects the quality of printing.

- Interruption of the process is possible with large and long-term projects, which leads to defects on the finished model.

Resin Pump simplifies printing with photopolymer resin and ensures consistently high quality results. Formlabs accessories are designed specifically for the brand’s 3D printers, so they perfectly optimize the printing process, making it simpler and better quality.