- Stock: In Stock

- Product code: 00-00011643

- Shipping Weight: 10.50kg

- SKU: PD-FS-P12T-10-01

Strong and Ductile Nylon 12 Tough

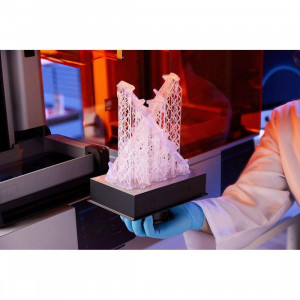

Strong Nylon 12 Tough Powder – powder for printing on the SLS printer Fuse 1+ 30W, which has the best-in-class ductility and the lowest refresh rate among Formlabs nylons. The tough Nylon 12 Tough powder creates strong and non-brittle parts, resistant to destruction, which print consistently and accurately.

- Nylon 12 Tough Powder can be printed on Formlabs Fuse 1+ 30W.

Features of Nylon 12 Tough

- Best-in-class percentage of recycled powder. Up to 80% reusable powder per build provides the best sustainability and affordability among nylon powders.

- High ductility. Reduces the risk of cracks and fractures. More than 50% more ductile than Nylon 12 powder.

- Dimensional accuracy. Manufacture parts with reduced warping throughout the build chamber.

- Affordability and cost-effectiveness. The price of Nylon 12 Tough Powder is on par with or not much higher than other Formlabs powders, making it an excellent option for prototyping and concept validation.

- Biocompatibility. The material is certified for biocompatibility, so it can be used for printing in medical applications.

- Nylon 12 Tough Powder should not be printed with virgin powder. Learn more about powder aging and layer temperature settings.

Applications

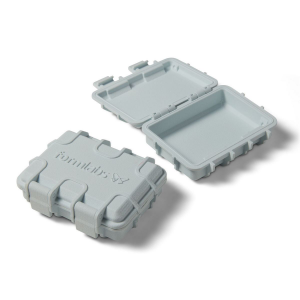

A 3D printing material that combines strength and flexibility, ideal for creating strong and deformation-resistant parts. Thanks to its increased ductility, Nylon 12 Tough allows for printing complex geometries with reduced risk of cracks and fractures. Use it to create prototypes that closely mimic the behavior of the final product, with precise dimensions and minimal warping.

- High-performance, impact-resistant, and accurate prototypes that mimic the functionality of the finished product.

- Long parts prone to deformation.

- Parts requiring ductility; locks, ratchets, hinges.

- Strong and ductile parts.

- Prototyping, concept validation, minimally viable products (MVP).

All questions regarding this product can be addressed to our specialists, contacts in the section "Our Contacts".

Download Files

Technical Data Sheet, PDF (EN)

Buy in Ukraine strong SLS powder for 3D printing Nylon 12 Tough

Fuse 1 | Fuse 1+ 30W | |

Nylon 11 | ✔ | ✔ |

Nylon 11 CF | ✔ | |

Nylon 12 | ✔ | ✔ |

Nylon 12 White | ✔ | |

Nylon 12 Tough | ✔ | |

Nylon 12 GF | ✔ | ✔ |

TPU 90A | ✔ | ✔ |

Polypropylene | ✔ |