- Stock: In Stock

- Product code: 00-00012985

- SKU: PKG-FS1-FB-PS-01

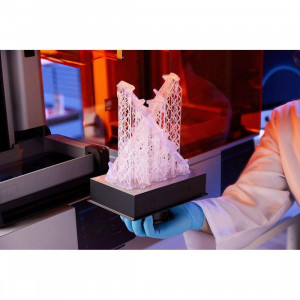

Fuse Blast Polishing System – fast polishing of SLS prints

Formlabs offers the Fuse Blast Polishing System, an optional upgrade to Fuse Blast that makes polishing SLS prints quick and easy. This kit helps to achieve a smooth, semi-glossy, and paint-ready surface on SLS printed parts. Get ready-to-use parts with a great look and feel.

This one-step add-on to your Fuse Blast cleans and polishes your parts directly from the Fuse Sift without the need for another Blast.

What’s in the box?

- Fuse Blast Polishing Module × 1

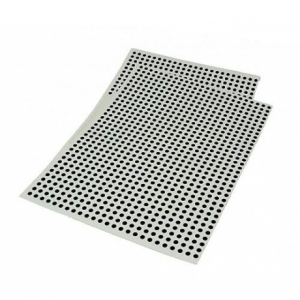

- Fuse Blast Polishing Media × 2

- Fuse Blast Polishing Agent × 1

- Fuse Blast Polishing Mesh × 1

The perfect surface for your 3D parts

- Get professional finished parts. Produce professional-looking SLS parts with a smooth, semi-glossy surface that’s ready to paint without any changes to your workflow.

- Easy to combine with Fuse Blast. Easy to install, add-on for any Fuse Blast without the need for an additional Blast.

- Reliable results. By sealing the surface with a polishing medium, as opposed to abrasive smoothing or chemical surface melting, surface roughness is reduced without removing material or small parts. No more rough surface finishing.

- Inexpensive solution. This is the most affordable polishing option on the SLS market. A very cost-effective alternative to automatic blasting machines and steam smoothing systems that require stand-alone installations and/or specialized knowledge/training.

How does it work?

Whereas standard glass blasting leaves a rough, matte finish, the Fuse Blast Polishing System cleans and smooths parts in one step by impact polishing. The Polishing Module dispenses and sprays a small amount of polishing agent solution into the jet to condition the polishing media. The Polishing Media is a soft, spherical polymer ball that lasts much longer than glass media.

- The Polishing Media will clean and polish your part directly from the Fuse Sift (no glass blasting is required).

- Polishing with Fuse Blast does not abrade the material – it creates a smooth surface by compacting the surface, similar to shot blasting.

- High blast pressure (60 psi) is required, which is achieved by using adaptive airflow. Fuse Blast’s Adaptive Airflow feature allows lower horsepower compressors to handle these increased airflow needs by pausing the cycle while the compressor charges. This provides a continuous, hands-on experience for cleaning and polishing SLS-ready parts.

Technical characteristics

- Polishing time – 20-60 minutes

- Service life of the polishing media – > 100 blast cycles (no breakage)

- Explosive pressure – Recommended minimum 60 PSI

- Service life of the polishing agent – 7 ml of polishing agent is diluted in 750 ml of water. One 120 ml bottle is enough for ~130 cycles in 45 minutes

- Recommended flow rate – 2 ml/min

- Water tank volume – 750 ml

- Compatibility – Fuse Blast