- Stock: In Stock

- Product code: 00-00012559

- Shipping Weight: 6.00kg

FastForm AlSi10Mg: Lightweight and Strong Aluminum Alloy for SLM

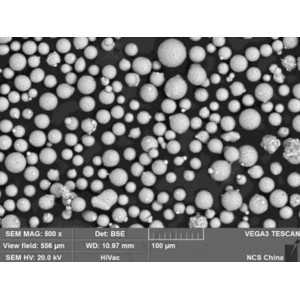

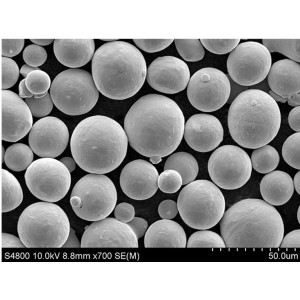

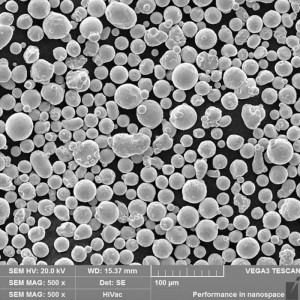

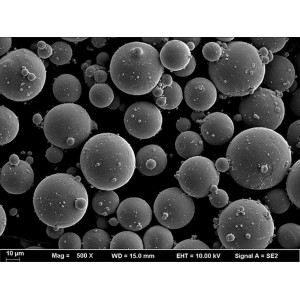

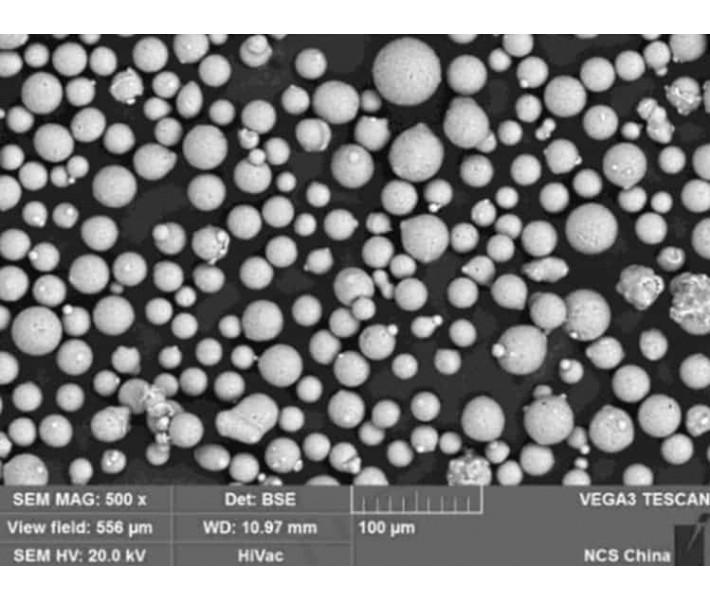

FastForm AlSi10Mg 15–53 µm (Aluminum-10% Silicon-0.5% Magnesium) aluminum powder, is one of the most popular materials for 3D printing using Selective Laser Melting (SLM) technology. Available in 5 kg packaging. This aluminum alloy combines lightness, high strength, excellent thermal conductivity, and good casting properties. FastForm AlSi10Mg is ideal for manufacturing components where low weight and complex geometric shapes are critical, finding applications in the automotive, aerospace, robotics, and thermal engineering industries.

Compatibility with Printers

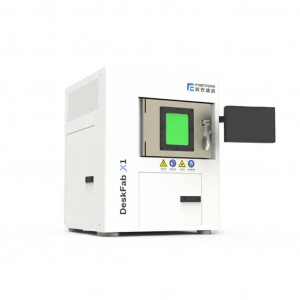

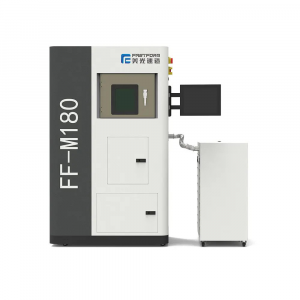

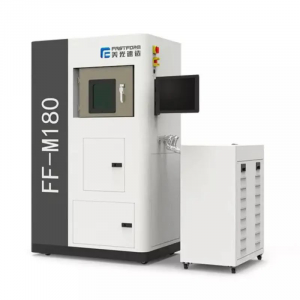

This aluminum alloy powder is compatible for 3D printing on FastForm SLM 3D printers: FF-M140C, FF-M220, FF-M300S, FF-M420.

For DeskFab X1 - use only for short-term printing. Long-term use is not advised.

Optimal Material Properties

The AlSi10Mg alloy, with its nominal chemical composition (about 10% silicon and 0.5% magnesium), provides parts printed using the SLM method with high strength and hardness after heat treatment. The addition of silicon improves the flowability of the material in the molten state, which contributes to the high-quality formation of complex shapes, and magnesium increases strength.

The powder fraction size of 15–53 micrometers is optimal for SLM processes, ensuring excellent flowability and uniform melting. This contributes to high printing precision, minimal porosity, and high surface quality of finished products.

Key Technical Specifications

Nominal Chemical Composition (wt.%)

- Aluminum (Al): Balance (allowable deviations)

- Silicon (Si): 9.5 - 10.5

- Magnesium (Mg): 0.20 - 0.45

- Titanium (Ti): ≤ 0.05

- Manganese (Mn): ≤ 0.45

- Copper (Cu): ≤ 0.05

- Iron (Fe): ≤ 0.55

- Nickel (Ni): ≤ 0.05

- Lead (Pb): ≤ 0.05

- Zinc (Zn): ≤ 0.10

- Tin (Sn): ≤ 0.05

- Nitrogen (N): ≤ 0.05

- Others (single): ≤ 0.05

- Others (total): ≤ 0.15

Technical Characteristics (for 15-53 µm fraction)

- Particle Size Distribution (D10): 15 - 22 µm

- Particle Size Distribution (D50): 25 - 35 µm

- Particle Size Distribution (D90): 50 - 55 µm

- Apparent Density (g/cm³): > 1.35

- Oxygen Content (ppm): < 500

Applications of FastForm AlSi10Mg

The combination of lightness, strength, and thermal conductivity makes FastForm AlSi10Mg metal powder ideal for the production of:

- Automotive components. Engine parts, brackets, body elements where low weight and strength are important.

- Aerospace industry. Lightweight structural elements, housings, fasteners.

- Heat exchangers. Components with high heat dissipation efficiency.

- Robotics and drones. Lightweight and strong housings and functional elements.

Buy FastForm AlSi10Mg 15–53 µm aluminum metal powder for 3D printing in Ukraine

To purchase FastForm AlSi10Mg metal powder 15–53 µm in Ukraine, please contact 3DDevice. We have over 10 years of experience in the 3D technology field. We provide qualified consultations and assistance in selecting materials and equipment that will meet your tasks and budget, ensuring reliability and product quality for your innovative projects.