- Stock: In Stock

- Product code: 00-00011322

- Shipping Weight: 4.68kg

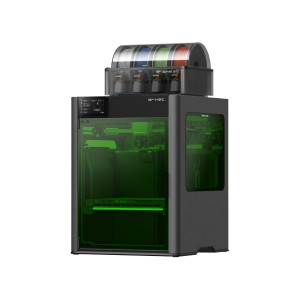

Bambu Lab AMS Automatic Material System

AMS (Automatic Material System) from Bambu Lab is designed for multi-color 3D printing. AMS allows the printer to automatically switch between different colors or types of materials, making the printing process more flexible and convenient. The system is designed for use with Bambu Lab 3D printers and supports up to four different materials simultaneously.

Achieve Multi-Color 3D Printing

Color, the highest expression of emotions, comes to life with Bambu Lab’s Automatic Material System (AMS). Now you can enjoy the freedom of printing in various colors and materials.

Effortless Support Removal

With AMS, Bambu Lab printers can use support material or soluble filament for easier support removal.

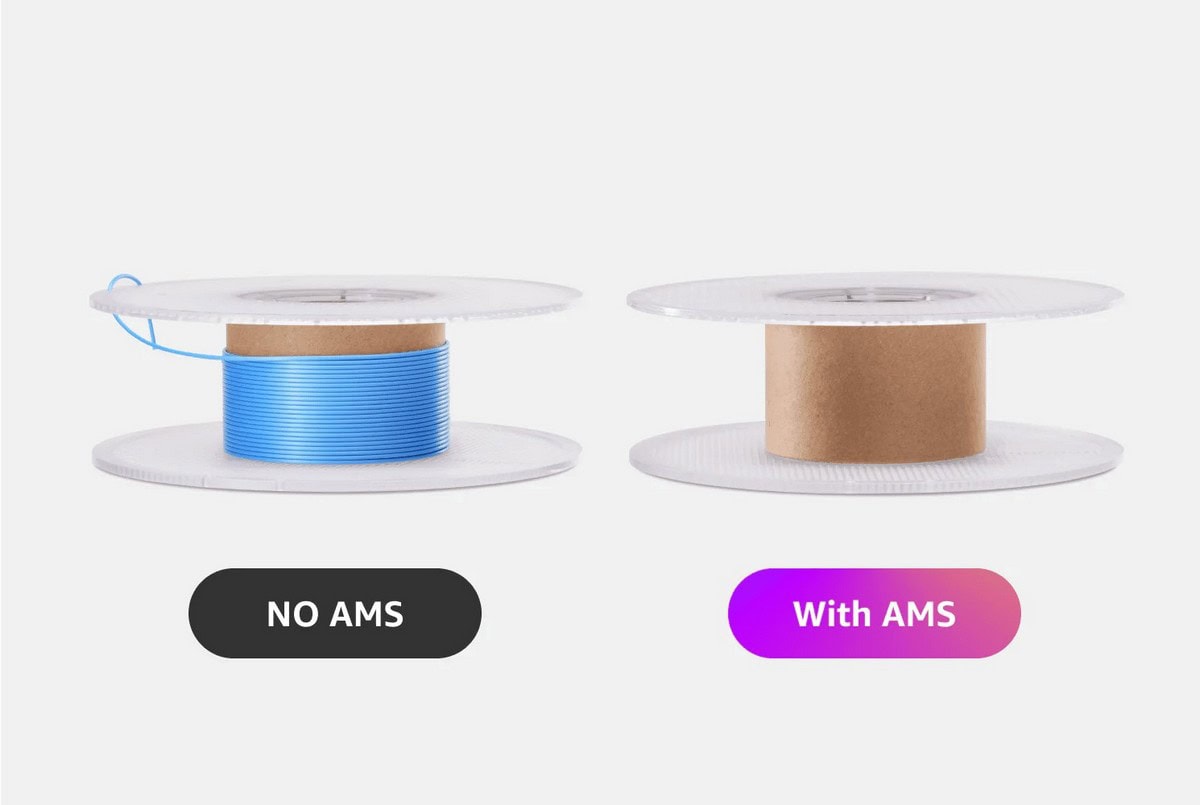

No More Residual Filament

Without AMS, when the filament runs out, you need to manually replace the spool, interrupting the print and leading to material waste.

With AMS, switching to a new spool is seamless, ensuring uninterrupted printing and reducing waste.

Backup Filament

Your print never stops thanks to automatic spool changing. The AMS backup filament function lets you rest easy knowing your printer won’t run out of filament while you sleep or are away. This ensures a smooth and continuous printing process, eliminates filament waste, and improves energy efficiency.

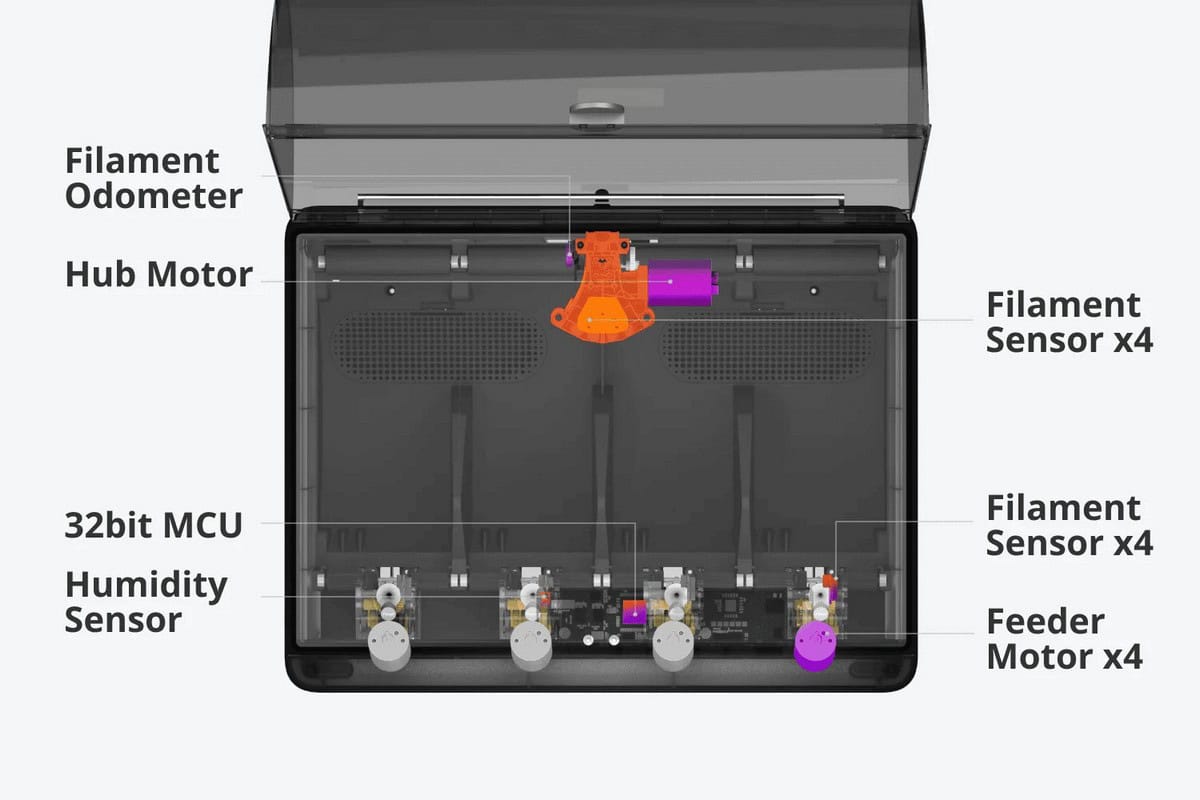

Smart System

Based on a 32-bit MCU, sensor arrays, actuators, and advanced algorithms, AMS achieves outstanding intelligence. It seamlessly handles filament loading and unloading, and provides efficient fault detection and resolution.

Filament Tangling Detection

If the filament on the print head encounters resistance, such as tangling or a jammed spool, AMS instantly detects the issue and pauses the print to avoid printing in the air.

Say Goodbye to Moist Filament

Filament that absorbs moisture can cause print quality issues, weak layer adhesion, and even nozzle clogging, leading to failed prints.

Keep Filament Dry

AMS features a sealed enclosure and uses a desiccant material to absorb moisture, keeping it away from the filament.

An integrated humidity sensor monitors the moisture level inside AMS and alerts the user if the humidity is too high or if the desiccant needs replacement.

To achieve the best print quality, it’s important to use dry filament.

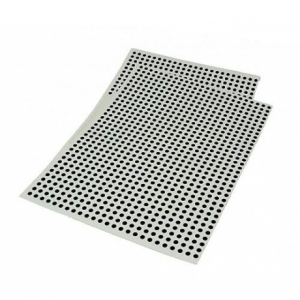

Automatic Filament Identification

Bambu Lab filaments come with RFID tags that AMS reads for automatic material identification and optimal setting application.

The RFID tag automatically synchronizes with Bambu Studio.

For filaments that are not Bambu Lab products, settings must be manually configured either in Bambu Studio or directly on the printer.

Supports Up to 16 Colors

Each AMS block from Bambu Lab has 4 filament slots, and you can install up to 4 AMS blocks in parallel, allowing for up to 16 colors for vibrant and unique prints. To achieve 16-color printing, connect 4 AMS blocks via the AMS hub.

Bambu Lab AMS Automatic Material System Specifications

| Product Size | 368 x 283 x 224 mm |

| Package Size | 445 x 350 x 320 mm |

| Product Weight | 2.5 kg |

| Weight with Packaging | 4.68 kg |

| Material | ABS |

| Supported Filament Types | PLA, PETG, ABS, ASA, PET, PA, PC, PVA (dry), BVOH (dry), PP, POM, HIPS, Bambu PLA-CF, PAHT-CF, PETG-CF |

| Unsupported Filaments* | TPE, TPU, PVA (moist), BVOH (moist), Bambu PET-CF, TPU 95A, other brands with carbon or fiberglass content |

| Filament Diameter | 1.75 mm |

| Supported Spool Size* | Width: 50-68 mm, Diameter: 197-202 mm |