Description

3D printer industrial Markforged FX20

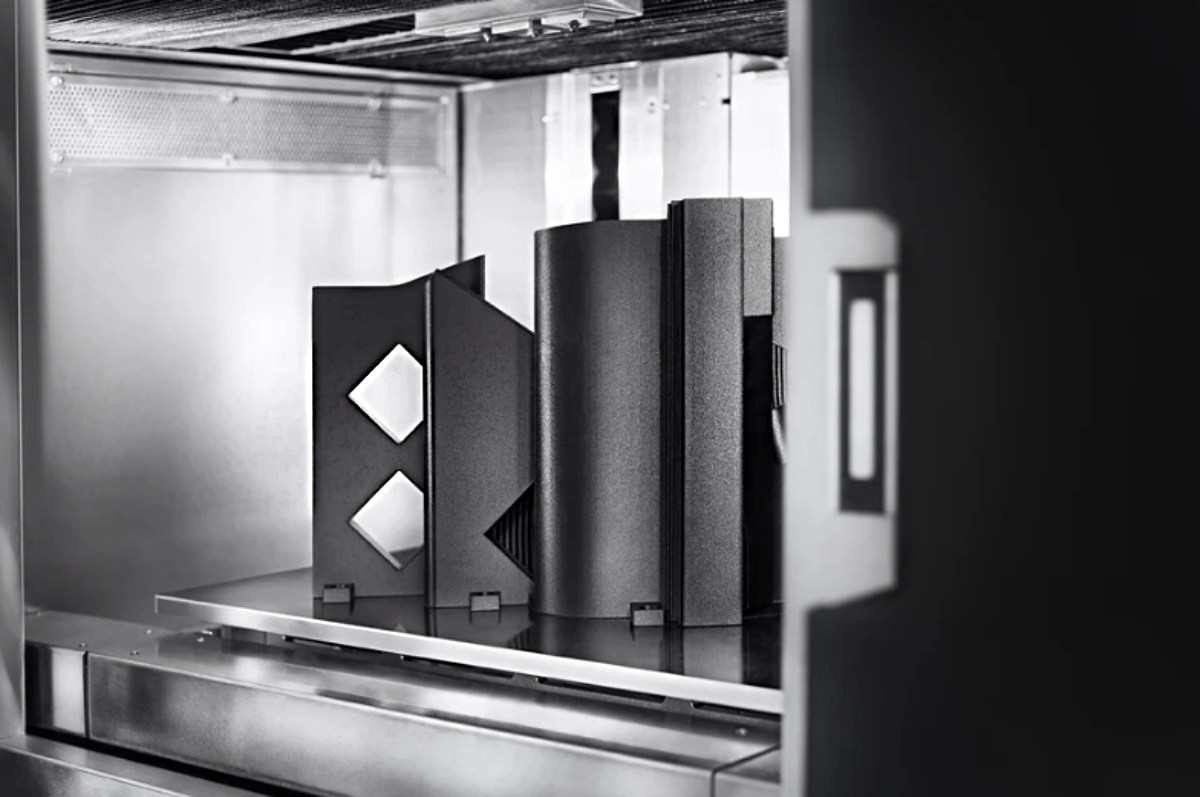

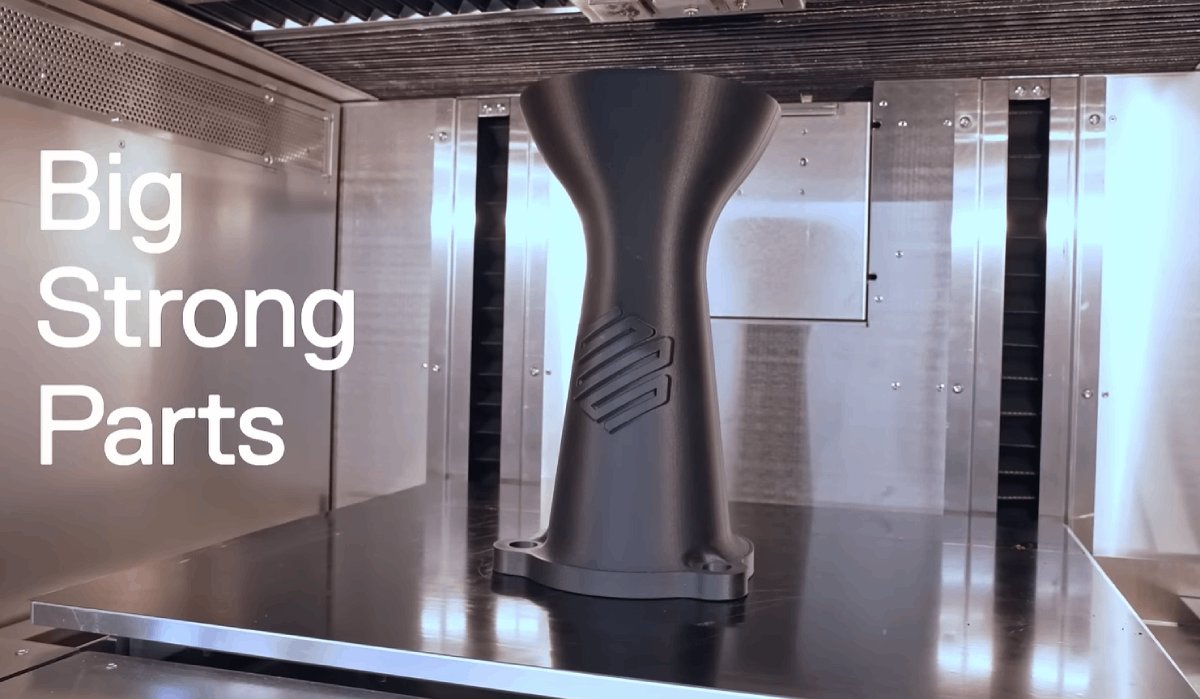

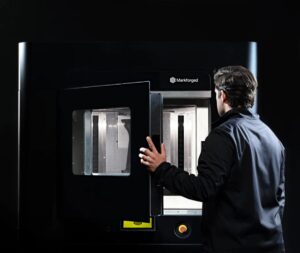

3D printer industrial Markforged FX20 is irreplaceable if you need to print large parts quickly and with high accuracy. Industrial developments have many technical features. The parameters of the printed model must fully comply with the specified ones. FX20 is capable of providing high printing accuracy, quality and optimal time frames.

Printing large parts on a 3D printer can take several days. Large-scale projects require reliable equipment that prints non-stop for a long time. Industrial 3D printers such as FX20 are developed to solve such large-scale problems.

Features of the 3D printer Markforged FX20

- The device is designed to work with large-sized parts.

- The 3D printer is highly productive and designed for complex tasks.

- It is integrated with the Digital Forge platform, which expands its capabilities.

- The platform provides convenient control of printing processes.

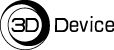

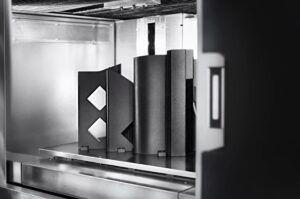

- The print chamber has a significant volume and is fully heated.

- Optimized for high print speeds and long production cycles.

- The touch screen simplifies operation. Integrated material handling minimizes downtime.

Industrial 3D printing on Markforged FX20, features:

- The volume of the working chamber is 525 × 400 × 400 mm. This is almost five times larger than that of the X7 model.

- The chamber is sealed and can be heated, which makes it universal for various materials.

- The print head is optimized for industrial production.

- The motion system ensures high speed and accuracy.

- The mechanical design is reinforced with modern sensors and controllers. The device is able to work quickly, while maintaining accuracy and reliability.

Industrial printer – the price of accuracy and innovation in design

The printer is equipped with a heat-resistant portal. This element is highly rigid and ensures stability of movement.

Linear encoders have a resolution of 2 μm. They guarantee precise position control in all axes. The closed loop extrusion control uses optical sensors. This solution allows you to monitor the feed rate of the material in real time.

Maximum temperature control of 200C°. Choose the material for 3D printing within the specified limits.

Premium equipment determines the accuracy and reliability of the equipment, forms its cost.

Features of the material feed system in Markforged FX20

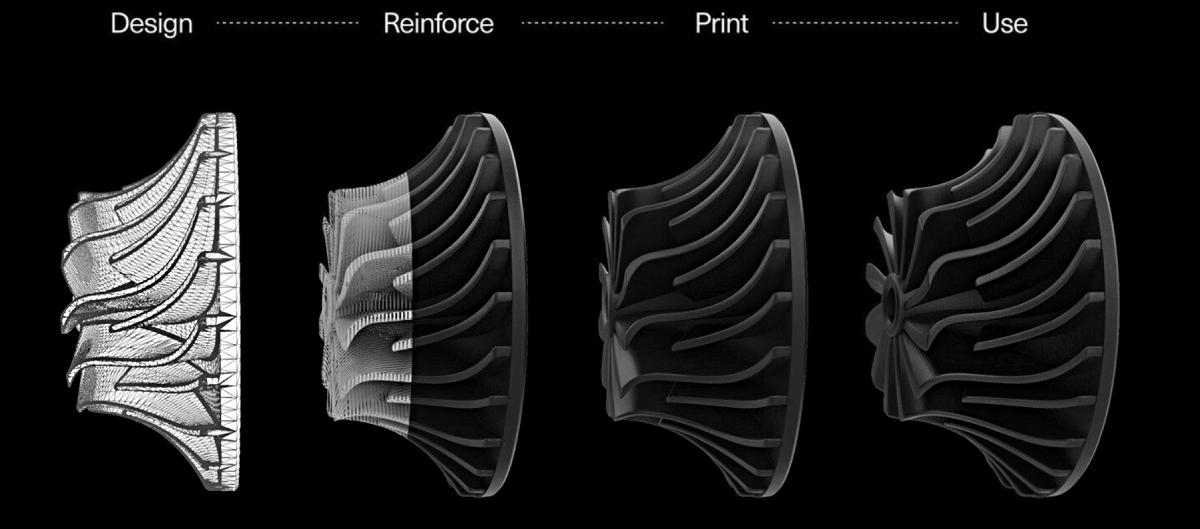

Materials are fed from a sealed cabinet into the upper chamber. In the chamber, the threads are laid along with the fiber along the feed chain. The technical characteristics of the FX20 allow the use of high-temperature plastic for 3D printing.

The print head has three nozzles. Two nozzles are used to work with plastic. The third is designed for continuous fiber.

The device is equipped with a direct drive system, which speeds up the work. All elements of the head heat up quickly and are adapted for intensive use.

Chamber temperature control and auto-calibration in the Markforged FX20 3D printer

- The heated chamber is equipped with an automatic alignment function.

- The device supports precise temperature control, which makes operation easier.

- The FX20 is the only printer in the Markforged line that works with ULTEMTM 9085 filament.

- Self-calibration is fully automatic. Manual bed leveling is not required. The vacuum aluminum platform provides a flat base for printing.

Drying 3D plastic, temperature, and humidity control on the screen

- The FX20 has a sealed material drawer with four compartments.

- Each compartment is equipped with a sensor that monitors humidity with an accuracy of 0.04%.

- Two active spools allow you to print with two polymer materials simultaneously.

- Input motors provide smooth filament feed. The device supports XL spools with a volume of 3200 cc, which increases the time of continuous operation.

- A 7-inch touch screen allows you to configure, start printing and monitor the printer status.

Markforged FX20 Specifications:

| Printing Technology | Continuous Fiber Reinforcement (CFR), fusion of threads |

| Build Field (mm) | Single-nozzle builds: 525 x 400 x 400 mm Multi-nozzle builds: 500 x 400 x 400 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 3 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 50 – 250 |

| Extruder Construction Type | Extruder with built-in motor, 3-nozzle design (2 – plastic, 1 – continuous fiber) |

| Leveling System | Kinematic connection of the printing platform – flat with an accuracy of up to 80 µm Laser leveling of the platform, active calibration of the print |

| Maximum Chamber Temperature (°C) | 200 |

| Automatic Filament Switching | Yes |

| Platform Material | Flat vacuum aluminum platform |

| Internal Part Geometry | Closed cell filling with continuous fibre reinforcement |

| Supported Materials | Vega™*, ULTEMTM 9085 filament, Onyx®, Onyx FR Continuous Fibers: Carbon Fiber, Fiberglass*, Aramid Fiber (Kevlar®)*, High Temperature Carbon Fiber, Carbon Fiber FR |

| Control | Temperature Control Up to 200°C steady-state |

| Features | Precision design Continuous fiber reinforcement (CFR) The volume of the printing chamber is 84 l |

| Software | Eiger |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 200-240 VAC 2W+PE 40A // 200-240 VAC 3Ø+PE 24A //347-415 VAC 3Ø+N+PE 14A; 50-60 Hz |

| Manufacturer Country | USA |

| Certifications | IEC/UL/CSA 62368-1 certified, CE Marked, EU Machinery Directive compliant |

| Weight Netto (kg) | 530 |

| Dimensions Netto (mm) | 1325 x 900 x 1925 |

Reviews

There are no reviews yet.