Селективне лазерне спікання – що це?

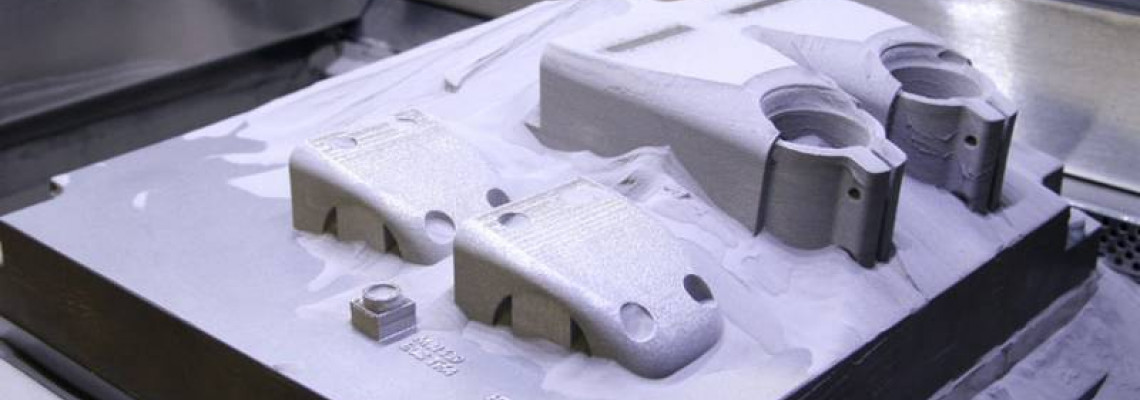

Більш правильна назва цієї методики – вибіркове лазерне спікання (від англ. Selective Laser Sintering, SLS). Це одна з методик 3D друку, широко застосовувана в промисловості. Селективне лазерне спікання доступне виключно на дорогих професійних 3D принтерах і відрізняється високою якістю виробів. З її допомогою можна досягти результату, наближеного до відтворення виробів методом лиття під тиском.

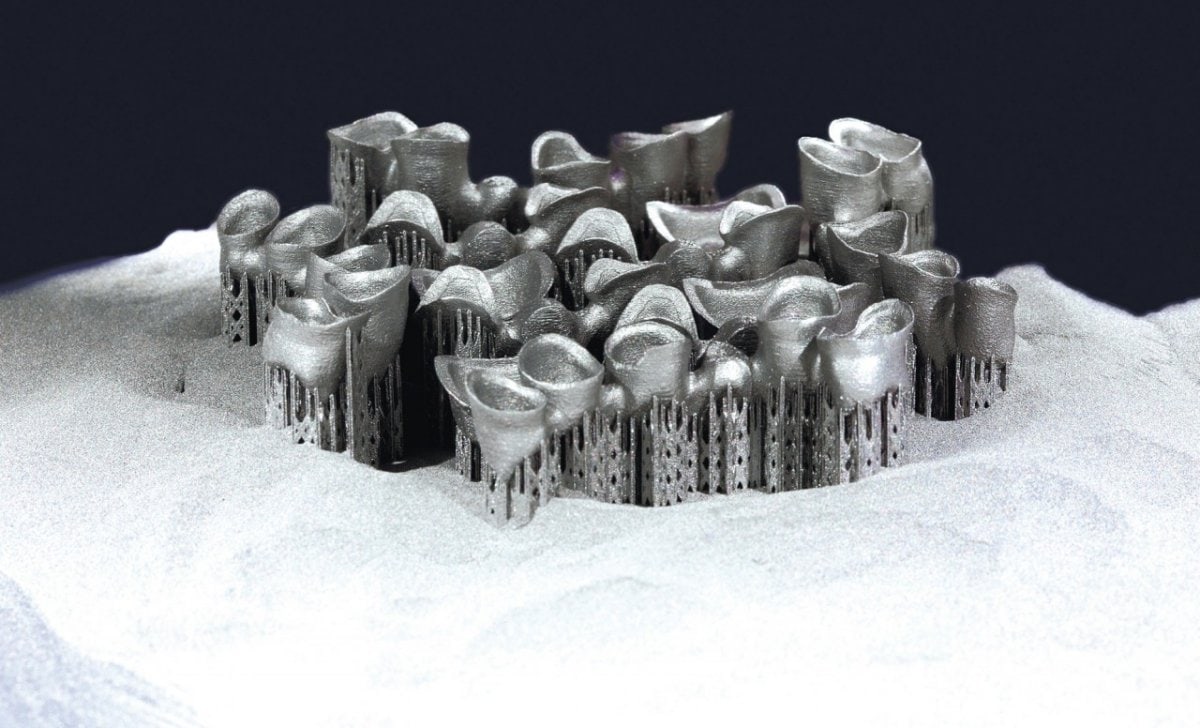

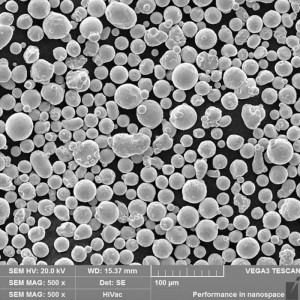

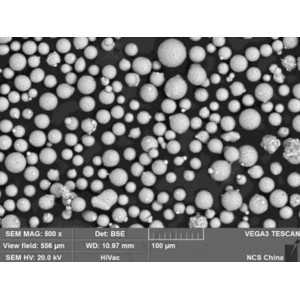

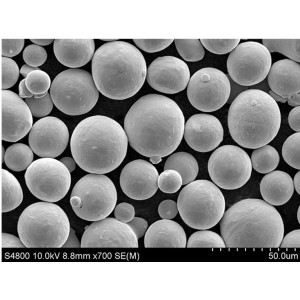

Селективне лазерне спікання, як і багато інших промислових методик адитивного виробництва, використовує в якості матеріалу порошки та порошкові суміші. Ця методика дозволяє створювати повністю металеві об'єкти за лічені години. А можливість виготовлення виробів складної форми пояснює її популярність серед промислових організацій з усього світу.

Принцип дії

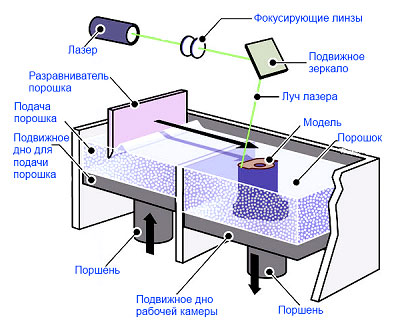

У чому ж суть методики? Давайте розберемося, як функціонує селективне лазерне спікання. Основною вимогою, як і в будь-якій іншій технології 3D друку, є наявність готової 3D моделі, що відповідає певним вимогам (детальніше тут). Саме за нею і буде відтворюватися виріб. Сама технологія досить проста. Спеціальне відділення 3D принтера заповнюється витратним матеріалом, після чого запускається друк. Цікаво, що безпосередньо перед відтворенням порошок розігрівається практично до температури плавлення.

За допомогою лазерної установки і скануючого дзеркала промінь лазера направляється на необхідні ділянки порошку, спікаючи їх разом шар за шаром. Після спікання першого шару вирівнюючий механізм додає тонкий шар порошку поверх нього, і процес відбувається заново до повного побудови об'єкта. Тобто, відтворення об'єкта відбувається знизу-вгору, а за рахунок заповнення камери порошком не потрібно будувати підтримуючі структури. На зображенні вище наочно продемонстровано пристрій SLS 3D принтера для кращого розуміння принципу методики.

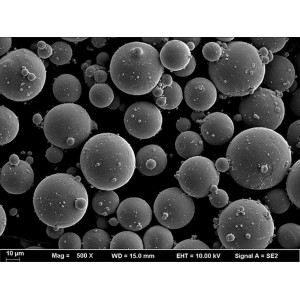

Застосовувані матеріали

Селективне лазерне спікання не може похвалитися великою різноманітністю кольорових витратних матеріалів, як, наприклад, FDM або SLA. Однак це не означає, що вибір обмежений. Справа в тому, що SLS друк орієнтований на промислові цілі, за рахунок чого і матеріали виробляються відповідні. На сьогоднішній день доступно безліч видів різноманітних порошкових сумішей, серед яких нейлон, кераміка, полістирол, і т.д.

Металеві порошки доступні в асортименті – сталь, алюміній, титан, кобальт і різноманітні суміші сплавів. Багато виробників роблять акцент на специфічні властивості композитів. Так, для SLS друку доступні ударостійкі, зносостійкі, жаростійкі, гнучкі, інженерні та термостійкі порошки. Деякі з них орієнтовані на більш конкретні завдання – наприклад, на виготовлення деталей для аерокосмічного виробництва.

Переваги та особливості

Що стосується особливостей, слід відразу відокремити селективне лазерне спікання від іншої схожої технології 3D-друку – селективного лазерного плавлення (SLM). Різниця між ними в тому, що SLS забезпечує лише часткове плавлення порошку, необхідне лише для його об'єднання в єдиний елемент. SLM же плавить частинки повністю, спікаючи порошок в монолітний виріб. Що стосується переваг, можна виділити наступні плюси:

- Велика область побудови в 3D принтерах. Промислове обладнання для SLS 3D друку зазвичай обладнане великою областю побудови, що дозволяє створювати не тільки великі деталі, але і виконувати дрібносерійне виробництво;

- Висока якість 3D друку. Ця методика дозволяє практично повністю уникнути видимої пошаровості на моделі, а відсутність опор також благотворно позначається на якості виробів;

- Відсутність необхідності в побудові опор. Селективне лазерне спікання дозволяє створювати вироби складної геометрії без необхідності побудови опорних структур. Це не тільки розширює можливості друку, але і добре позначається на якості поверхні виробу;

- Висока швидкість і продуктивність. За рахунок того, що матеріал не плавиться повністю, SLS 3D принтери працюють набагато швидше за інших своїх порошкових побратимів. Вища швидкість друку – вища продуктивність виробництва;

- Можливість виготовлення готових виробів. Завдяки властивостям витратних матеріалів цю технологію 3D друку цілком реально використовувати для виробництва кінцевих продуктів.

Сфери застосування

Що стосується сфер застосування, селективне лазерне спікання популярне виключно в промисловості через високу вартість витратних матеріалів і обладнання, а також великі габарити останніх. Тому і сфери застосування відповідають:

- Функціональне тестування;

- Прототипування;

- Дрібносерійне виробництво;

- Виготовлення готових функціональних компонентів;

- Виготовлення виробів зі складною геометрією;

- Виробництво аерокосмічних компонентів;

- Розробка і виготовлення автомобільних деталей і т.д.

Крім того, відомі випадки застосування цієї методики в дизайні та творчості. Втім, це не дивно, адже технологія 3D друку не тільки розширила межі можливостей, але і відкрила нові можливості для різних сфер нашого життя.

На цьому наша стаття добігає кінця. З усіх питань, пов'язаних з придбанням обладнання або наданням послуг 3D друку, звертайтеся до нас за телефонами або електронною поштою, вказаними в розділі «Контакти».

Залишити коментар