- Stock: Price on request

- Product code: 00-00013603

- Shipping Weight: 62.40kg

DELFIN MTL 452 INERT Z21: Professional Solution for Handling Explosive Dust

Industrial enterprises that work with conductive and explosive dust face unique challenges. The DELFIN MTL 452 INERT Z21 represents a new generation of industrial vacuum cleaners specifically designed for operation in high-risk explosion zones, where personnel safety is the top priority.

ATEX Certification and Safety Standards

The equipment is certified according to ATEX Directive 2014/34/EU for internal Zone 20 and external Zone 21, making it suitable for operation in environments with a high level of explosion hazard. This certification ensures that every component of the system meets the strictest European safety requirements.

Areas of Application

- Metallurgical Industry: removal of aluminum and steel dust

- Special Alloy Production: handling of Inconel, lithium, tantalum, zirconium

- Chemical Manufacturing: processing of reactive powdered materials

- Pharmaceutical Industry: cleaning in controlled environments

Innovative Inertization System

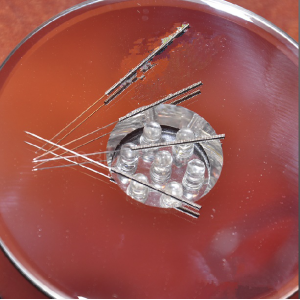

The revolutionary inert liquid bath technology is at the core of the equipment's safety. The system uses an inert oil that instantly neutralizes explosive dust upon suction.

Principle of Inertization

The suctioned material passes through a bath of inert liquid, where potentially explosive particles are immediately neutralized. This prevents the accumulation of an explosive atmosphere inside the vacuum cleaner and ensures the highest level of operator protection.

Benefits for Production

Continuous Operation and Reliability

The equipment is designed for intensive and continuous operation. A powerful brushless motor provides stable performance throughout the work cycle, minimizing production downtime due to maintenance.

Multi-Level Filtration System

The two-stage filtration system includes an anti-static M-class polyester filter and an absolute filter, ensuring maximum air cleaning efficiency. This approach not only enhances safety but also maintains a clean working environment in accordance with the strictest hygiene standards.

Design Solutions and Ergonomics

Corrosion-Resistant Construction

The modular tank is made of AISI304 stainless steel, ensuring long-term operation even in aggressive industrial conditions. The material resists corrosion and chemical exposure, maintaining its properties over many years of intensive use.

Ease of Maintenance

The easily removable collection container simplifies the safe disposal of waste. The integrated grounding system completely eliminates the risk of static discharge, which could otherwise trigger an explosion in hazardous environments.

Versatility of Application

Interchangeable Containers for Different Tasks

A unique feature of this model is the ability to quickly replace the inert bath container with a standard tank for routine floor and equipment cleaning tasks. This versatility makes the investment economically justified for enterprises with diverse needs.

Autonomous System Use

The inert bath system is also available as a standalone separator, allowing it to be used in conjunction with other ATEX-certified equipment. This opens additional opportunities for integration into existing production processes.

Economic Efficiency and ROI

Although the initial cost of specialized equipment may seem high, the real economic benefits become clear over the long term:

- Reduction of production incident risks and downtime

- Compliance with insurance and regulatory requirements

- Decreased costs for hazardous waste disposal

- Long service life without frequent replacement

Supporting Production Standards

Regulatory Compliance

For modern enterprises, it is crucial not only to perform tasks but to do so in accordance with international safety and environmental standards. The DELFIN MTL 452 INERT Z21 allows production processes to meet the strictest requirements.

Prevention of Emergencies

The built-in overpressure valve provides an additional level of protection, automatically releasing pressure in critical situations. This feature can prevent serious industrial incidents and their consequences.

Technical Data

| Parameter | Specification |

|---|---|

| Use Zone | Haz Location (20 Int / 21 Ext) |

| Marking | II 1/2D Ex h tb IIIC T80°C (Int) / T95°C (Ext) Da/Db |

| EX Category | CE EX 21 1/2D |

| Voltage | 115/230 V – 50/60 Hz, 1~ |

| Power | 1.1 kW |

| Current Draw | 8 A |

| Max Waterlift | 2250 mmH₂O |

| Max Airflow | 215 m³/h |

| Suction Inlet | 50 mm |

| INERT Liquid Capacity | 10 L |

| Inert Liquid + Vacuumed Material Capacity | 15 L |

| Noise Level | 74 dB(A) (EN ISO 3744) |

| Dimensions | 61 × 66 × 133 cm |

| Weight | 52 kg |

| Primary Filter | Star / Tasche |

| Filter Surface, Diameter | 20,000 cm² – 420 mm |

| Filter Media, Class | Polyester – ANT M |

| Air Load on Filter | 108 m³/m²/h |

| Cleaning System | Manual |

| Absolute Filter Class H | Included |

| HEPA Filter Surface | 11,000 cm² |

| Filtration Class | H14 with 99.995% efficiency (MPPS method) |