- Stock: In Stock

- Product code: 00-00011627

- Shipping Weight: 76.00kg

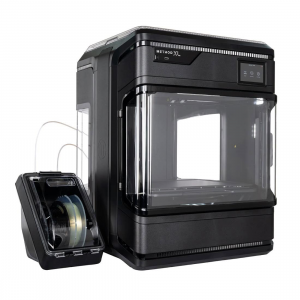

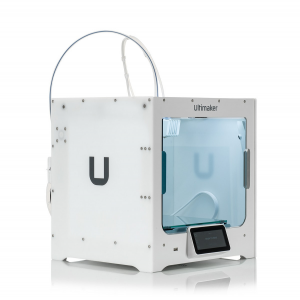

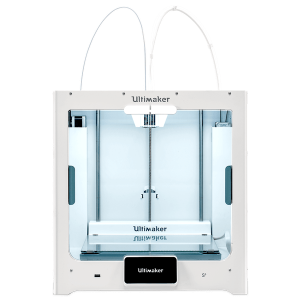

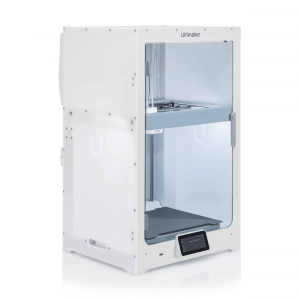

UltiMaker Method XL – industrial quality at affordable prices

Meet the professional UltiMaker Method XL 3D printer with a large printing area that creates precision engineering-grade ABS prototypes. Ensured by a heated build plate and active build chamber that guarantee strong layer adhesion and allow you to create complex geometries on water-soluble supports and protects air quality thanks to the built-in HEPA filter.

Print large parts with industrial-grade materials and high dimensional accuracy – the best solution for engineering applications.

The Method XL is supported by most advanced polymers and software platforms.

Key features of the UltiMaker Method XL

- Extremely large print volume of 305*305*320 mm.

- Active heating chamber up to 100 °C.

- Optimized ABS double extrusion.

- Flexible build plate heated up to 105 °C.

- High dimensional accuracy.

- External filament box.

- High print success rate and low number of jams.

- High-performance materials: ABS-R, ABS-CF.

- Soluble support materials.

- CloudPrint remote management.

- Printing with third-party materials using the LABS extruder.

- Integrated air filters.

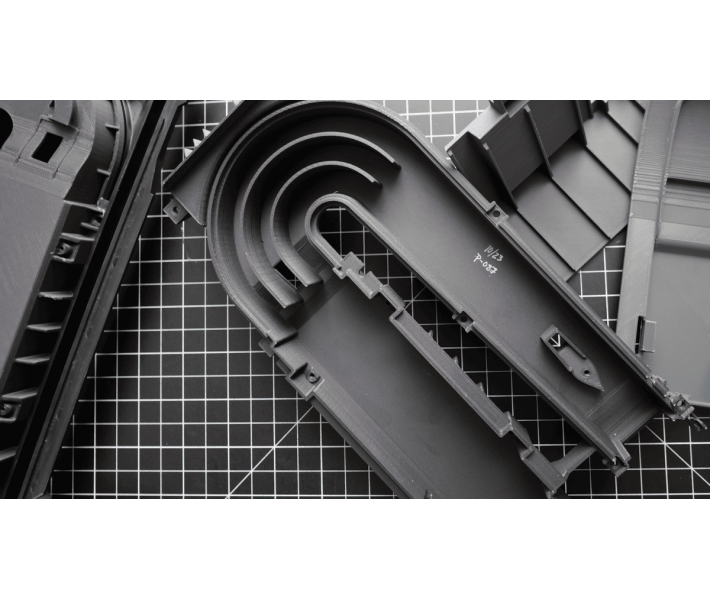

Large-scale prototypes in engineering-grade ABS

Print robust, large-scale prototypes in engineering-grade ABS that meet your specifications.

With the Method XL, engineers can design, test and produce large-scale models and prototypes in durable, production-grade ABS for their manufacturing needs with unlimited geometric freedom.

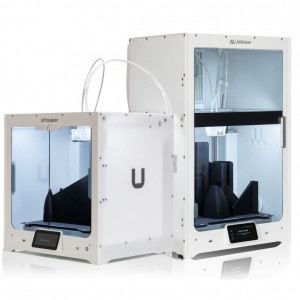

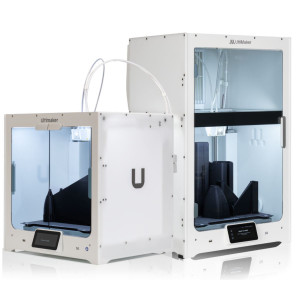

Large print volume

The extremely large build volume of the Method XL makes it the best 3D printing solution for large-scale projects. Print with industrial materials with exceptional dimensional accuracy without having to compromise on part size.

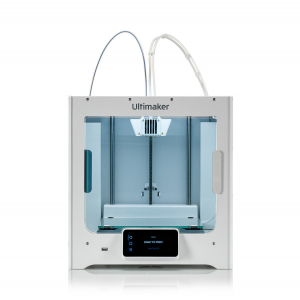

Double extrusion in the entire XYZ print volume

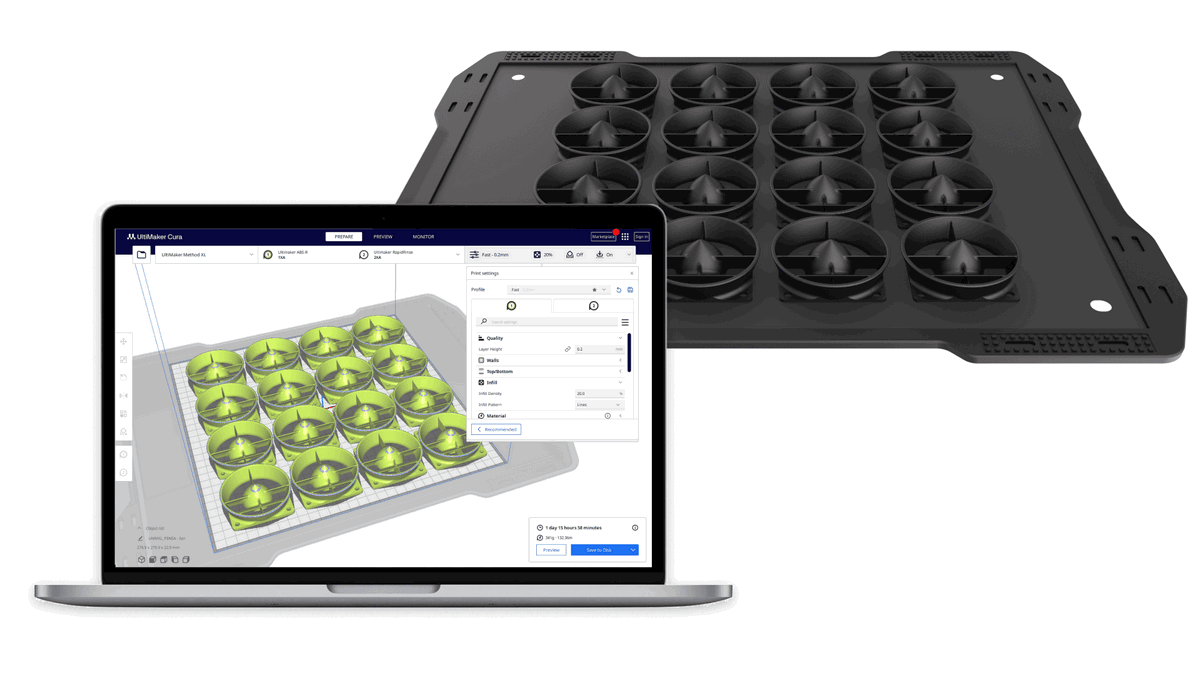

UltiMaker Cura for Method XL

UltiMaker Cura now includes print profiles for the Method XL.

Unlock the full flexibility of 3D printing with the Method XL with UltiMaker Cura. You can use the professionally customized print profiles in Cura to slice files for Method XL.

With over 600 print settings, safe 3D printing is now available in UltiMaker Cura.

Heating of the build chamber and build platform

Heated print chamber and heated build plate with VECT thermal management system.

The patented Variable Ambient Temperature (VECT) 100 heats and controls the print environment evenly.

High precision for low tolerances

Method XL has been specifically designed to maintain exceptional dimensional accuracy and tight tolerances when printing even the largest ABS parts. Method XL not only avoids problems with warping and layer adhesion, but also produces massive parts with industrial precision.

- Dimensional accuracy of +/- 0.2 mm or +/- 0.002 mm per mm stroke*.

*(Whichever is greater.) Based on internal testing of selected geometries.

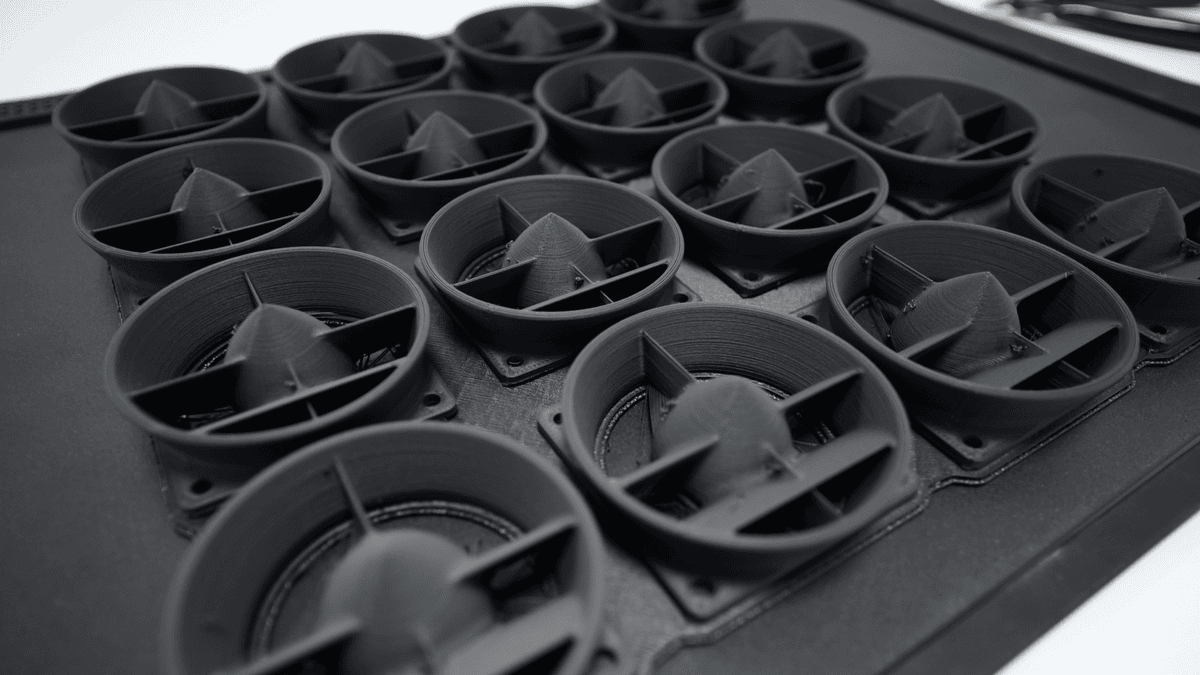

Fast dissolving supports for ABS

RapidRinse in Method XL provides the fastest support removal for complex FDM prints. Create the geometries you need – in any orientation. Then watch these water-soluble supports dissolve before your eyes.

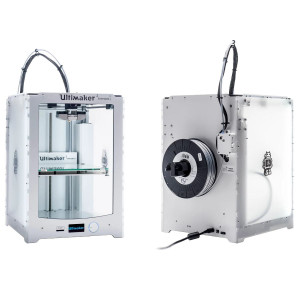

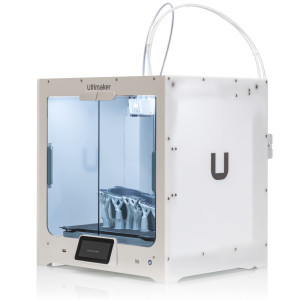

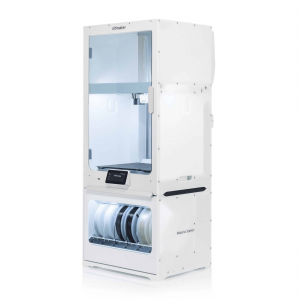

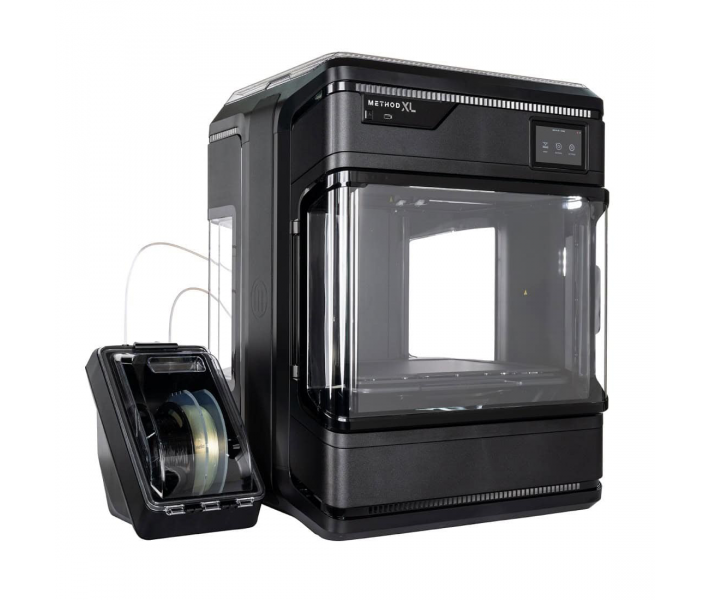

External Material Case

The moisture-proof outer Material Case for the Method XL ensures maximum performance of your professional materials.

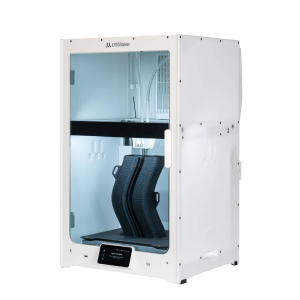

Direct-drive extruders

Reliable 3D printing in ABS-R or ABS Carbon Fiber to simulate the material quality of injection molded plastic.

Two filters, one seamless print

Both the HEPA and activated carbon filters are integrated into the machine, ensuring that you can use the Method XL indoors without worrying about harmful fumes or pungent odors.

UltiMaker Method XL is trusted by global brands

Trusted by the best engineers in the world: Toyota, Honda, Boeing, Kuka, Pfizer, Lockheed Martin.

Available materials

Produce end-use tools and parts with improved strength, stiffness, and temperature tolerance: ABS-R, ABS Carbon Fiber, N12-Carbon Fiber, ASA, SR-30, Rapid Rinse.

Compatible extruders

Direct extrusion printheads with integrated gearbox for optimal print results. Quickly change material groups to prevent cross-contamination.

- 1C extruder

- 1XA extruder

- Extruder 2XA

- LABS extruder

What’s in the box?

Everything you need to get started. The Method XL contains:

- Method XL × 1 3D printer

- 1C × 1 extruder

- 2XA extruder × 1

- Material box × 1

- Flexible build plate × 1

Specifications

| Printing Technology | FDM |

| Build Field (mm) | 305*340*320 |

| Build Field For Dual Printing (mm) | 305*305*320 |

| Diametr Of Plastic (mm) | 1,75 |

| Maximum Nozzle Temperature (°C) | 300 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Filament Chamber Type | Closed |

| Heating The Chamber | Yes |

| Plastic Drying | Yes |

| Feeder Type | Direct |

| Nozzle Diameter (mm) | 0,4 |

| Supported Extruders | 1С, 1XA, 2XA, LABS |

| Maximum Chamber Temperature (°C) | 100 |

| Platform Heating | Yes |

| Maximum Platform Temperature (°C) | 105 |

| Platform Material | Removable, flexible build surface |

| Open Filament System | Yes |

| Supported Materials | ABS-R, ABS-CF, N12-Carbon Fiber, ASA, SR-30, Rapid Rinse |

| Running Noise, dB | 57.1 +/- 3 |

| Air Filter | HEPA filter, activated carbon filter |

| Control | 5″ full-color capacitive touchscreen |

| Supported File Types | STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG, G, GCODE, GCODE.gz, UFP |

| Software | CloudPrint, UltiMaker Cura |

| Connectivity | Wi-Fi, Ethernet, USB |

| Power Requirements | 100-240 VAC, 50-60 Hz, 12-8A |

| Power Output | 1500W |

| System Requirements | Mac OS, Windows |

| Warranty Period (months) | 12 |

| Weight Netto (kg) | Printer: 56.5; Material case: 1.9 |

| Dimensions Assembled (mm) | Printer: 655×565×815; Material case: 223×328×319 |