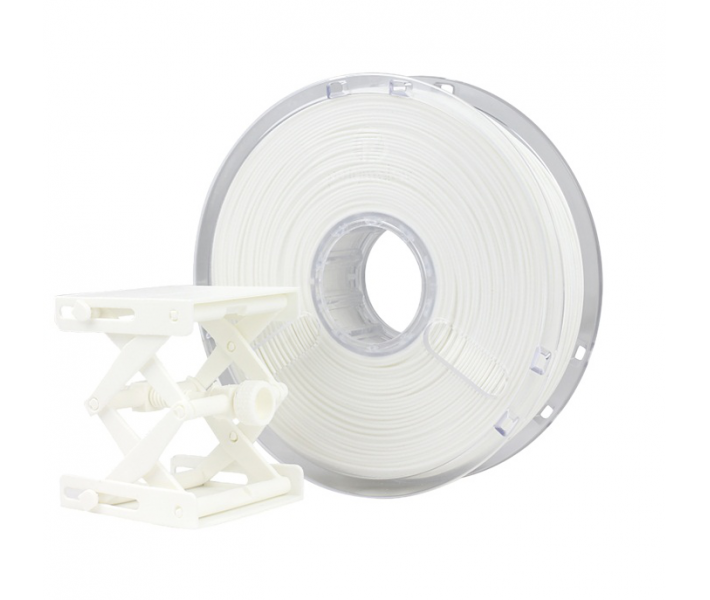

3D plastic Polymaker PC-Max, strong polycarbonate

- Stock: In Stock

- Product code: GEN-14459558

- Shipping Weight: 0.85kg

Based on 0 reviews.

-

Write a comment

₴2 790.00

Ex Tax: ₴2 790.00

Quantity:

High-strength 3D plastic Polymaker PC-Max

Polycarbonate is considered one of the strongest materials for 3D printing and is widely used in the manufacture of functional elements and finished products. Polymaker PC-Max 3D plastic is an improved version of the already rigid fiber and is ideal for a range of engineering applications. This material demonstrates excellent print quality with high mechanical strength, impact resistance, heat resistance, and fracture resistance. For easier and more comfortable 3D printing, the manufacturer recommends using Polymaker PC-Max 3D plastic with the universal BuildTak substrate, which provides good adhesion and prevents deformation of parts.

Polymaker PC-Max 3D plastic: properties

- Ultra-high rigidity. Polymaker PC-Max 3D plastic has the highest impact strength among its counterparts in the 3D printing market, which automatically expands its scope of application.

- Heat resistance. The material can withstand temperatures well above 110°C. It has virtually no competitors in this regard.

- Ease of use. Due to its strength, polycarbonate is more often used in industrial 3D printer models. However, Polymaker PC-Max 3D plastic opens up access to professional printing on desktop devices.

- Excellent mechanical strength. In virtually all deformation tests, this material outperforms ABS and PLA plastic.

- Easy post-processing. Polymaker PC-Max products are easy to post-process and can be sanded, primed, painted, and varnished as required.

Technical specifications

| Glass transition temperature | 113 ˚С |

| Density | 1,18 – 1,20 g/cm3 |

| Filament diameter | 1,75 mm, 3 mm |

| Tolerant deviation | ± 0.05 mm (On average ~ ± 0.02 mm) |

| Recommended printing temperature | 250 – 270 ˚С |

| Recommended printing speed | 30 – 90 mm/s |

| Recommended platform heating temperature | 80 ˚С |

| Color | White, black |

| Spool weight | 750 g |

Фізичні властивості

| Property | Test Method | Typical Value |

| Density (g/cm3 за 21,5 ˚С) | ASTM D792 (ISO 1183, GB/T 1033) | 1,18 – 1,20 |

| Glass Transition Temperature | DSC, 10 °C/хв | 113 °C |

| Softening Temperature of Plastic Filament (for 1.75 mm) | Користувацький метод | 127 – 130 °C |

| Moisture Content for Freshly Opened Plastic (%) | Термогравіметричний аналіз | ≤ 0.1% |

| Odor | / | Virtually Odorless |

| Solubility | / | Insoluble in Water |

Механічні властивості

| Property | Test method | Typical value |

| Modulus of elasticity (MPa) | ASTM D638 (ISO527, GB/T 1040) | 2048 ± 66 |

| Elastic strength (MPa) | ASTM D638 (ISO527, GB/T 1040) | 59,7 ± 1,8 |

| Elongation at break (%) | ASTM D638 (ISO527, GB/T 1040) | 12,24 ± 1,44 |

| Flexural modulus (MPa) | ASTM D790 (ISO 178, GB/T 9341) | 2044 ± 55 |

| Flexural strength (MPa) | ASTM D790 (ISO 178, GB/T 9341) | 94,1 ± 0,9 |

| Impact strength (kJ/m2) | ASTM D256 (ISO 179, GB/T 1043) | 25,1 ± 1,9 |

Material Parameters

Density (g/cm3)

1.18

3D Printing

Printing Temperature (°C)

250 - 270

Weight and Dimensions

Material Weight (kg)

0.75