- Stock: In Stock

- Product code: 00-00001614

- Shipping Weight: 1.40kg

Hard and rigid plastic for 3D printer PETG Carbon

PETG Carbon for 3D printer from Spectrum Filaments is a modified plastic for 3D printing. The filament is based on PET-G, to which 10% carbon fiber has been added. This composite material thus has significantly higher stiffness, hardness, and tensile strength, while maintaining low shrinkage and very good adhesion to create platforms typical of pure PET-G. The addition of 10% carbon fiber allows for matte surfaces of printed products, which significantly improves their aesthetic properties.

Tip: Due to the significant content of crushed carbon, it is recommended to use nozzles with a diameter larger than the standard value of 0.4 mm. The presence of carbon fiber can also cause wear and tear on standard nozzles; therefore, for long-term use of Spectrum Carbon PET-G, it is recommended to use hardened steel or ruby nozzles.

Characteristics of PETG Carbon Spectrum Filaments

- Increased hardness and stiffness compared to pure PET-G.

- Higher plasticization temperature compared to pure PET-G.

- Improved abrasion resistance.

- VICAT 80°C.

- Much higher compressive strength compared to pure PET-G.

- Good mechanical properties.

- High aesthetics, matte surface quality.

- No shrinkage after cooling.

What is printed with PETG Carbon

- Objects that need to be very rigid and hard while maintaining dimensional accuracy.

- Manufacturing components subjected to static compressive loads.

- Conceptual and demonstration prototyping in the development of finished and semi-finished products.

- Decorative parts with a matte surface (aesthetic properties).

- External structural elements that emphasize the product.

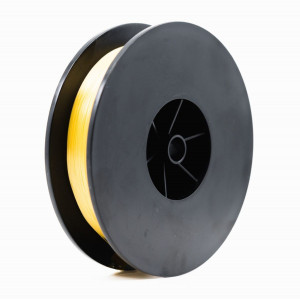

PETG Carbon plastic packaging

The 1.0 kg filament is wound on a transparent spool with information on the material type, diameter, color, and recommended print temperature. Each spool is vacuum-packed with a desiccant. All in the original Spectrum Filaments foil carton.

Spool dimensions

- Outer diameter – 200 mm

- Width – 67 mm

- Inner diameter – 52 mm

- Weight of an empty spool – ± 250 g

Checking the quality of 3D plastic filament

Spectrum Filaments is the only company in Poland and one of the few in the world that has a tool for checking purchased filaments. VERIFY YOUR SPOOL is the most accurate quality control system on the market, ensuring that Spectrum Filaments products meet its strict requirements.

The filament for 3D printers is produced by free extrusion, which is one of the most complex extrusion technologies due to the particularly significant influence of process parameters on product dimensions and material homogenization. During the production process, every 1 mm of Spectrum Filaments is continuously measured in 2 axes with an accuracy of ±0.8 μm, which allows for a high-quality end product. To prove this, Spectrum Filaments, as one of the few manufacturers in the world, has introduced the possibility of online presentation, individually for each coil produced:

- diameter stroke along the entire length of the coil;

- average diameter;

- ovality;

- standard deviation.

Specification

| Plastic diameter (mm) | 1,75 |

| Printing temperature (°C) | 230 – 255 |

| Bed temperature (°C) | 60 – 80 |

| Material | PETG |

| Diameter tolerance (mm) | +/- 0,03 |

| Density (g/cm3) | 1,32 |

| Surface finish | Matte, carbon look |

| Thermal Resistance (°C) | HDT B – 72 °C, VICAT – 80 °C |

| Colors | Black |

| Filament dryer | Not required |

| Ruby or hardened nozzle | Recommended |

| Closed chamber | Not required |

| Cooling (%) | 75 – 100 |

| Printing speed (mm/s) | 30 – 70 |

| Recommended wall thickness (mm) | 0.40 – 2.70 |

| Recommended layer height (mm) | ≥ 0.15 mm |

| Adhesive products | Not required (to increase adhesion or prevent warping: Dimafix, 3DLac, Magigoo) |

| Country Manufacturer | Poland |

| Plastic weight (kg) | 1,0 |

| Gross weight (kg) | 1,4 |