- Stock: In Stock

- Product code: 00-00012979

- Shipping Weight: 660.00kg

Available Options

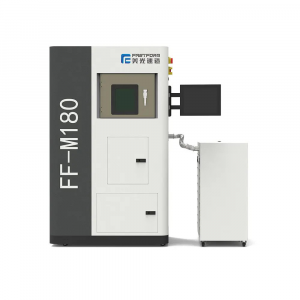

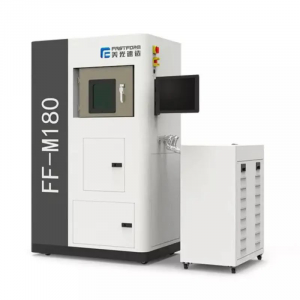

FastForm FF-M220

FastForm FF-M220 – an innovative 3D printer that performs metal alloy 3D printing from metal powder. The Selective Laser Melting (SLM) technology using two powerful 500 W lasers and allows you to quickly print complex 3D shapes in the thickness of the powder. The printer has an increased working chamber size of 220*140*100 mm and is specially designed for the dental industry.

Faster, more accurate, and more efficient metal alloy 3D printing

- Dual laser source. Printing speed has increased more than 2 times due to integrated high-power laser sources.

- Large print volume. Up to 320-350 teeth or 35 frames can be printed simultaneously on one substrate, which significantly increases productivity.

- Precision accuracy. The Scanlab galvanometer provides high accuracy and low drift, ensuring flawless results.

- Wide range of materials. Compatible with a variety of metal powders, including CoCr and titanium.

- Intuitive software. FastLayer and FastFab offer an easy-to-use interface and automated workflows.

Why choose FastForm FF-M220?

- High quality printed parts. Laser powder fusion ensures strong, durable parts.

- Reliability and durability. Built with high-quality components for long-term operation.

- Ease of use. Intuitive interface and automated actions minimize the need for operator intervention.

- Customer support. We provide comprehensive support from material selection to machine setup.

Benefits

- Increase production volume. Print large quantities of parts quickly.

- Reduce costs. Optimize material and energy use.

- Improve product quality. Highly accurate and detailed parts.

- Expand the range of services. Offer clients individual solutions based on the client’s own anatomy.

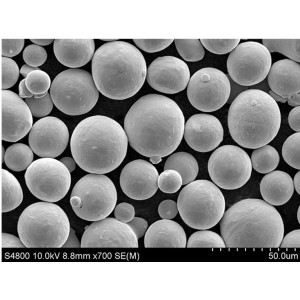

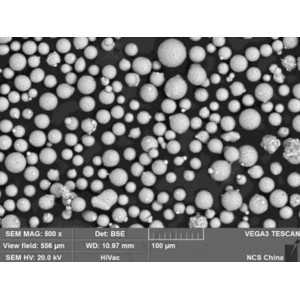

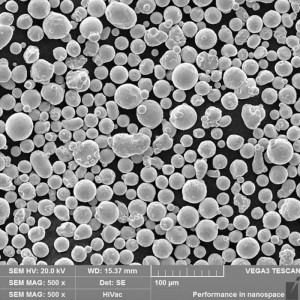

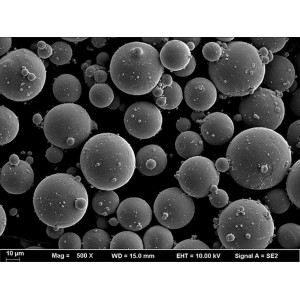

Metal 3D printer print samples

3D metal printing SLM on a FastForm FF-M220 printer is possible with the following alloys: cobalt-chrome, stainless steel, tool steel, titanium alloys, aluminum and nickel.

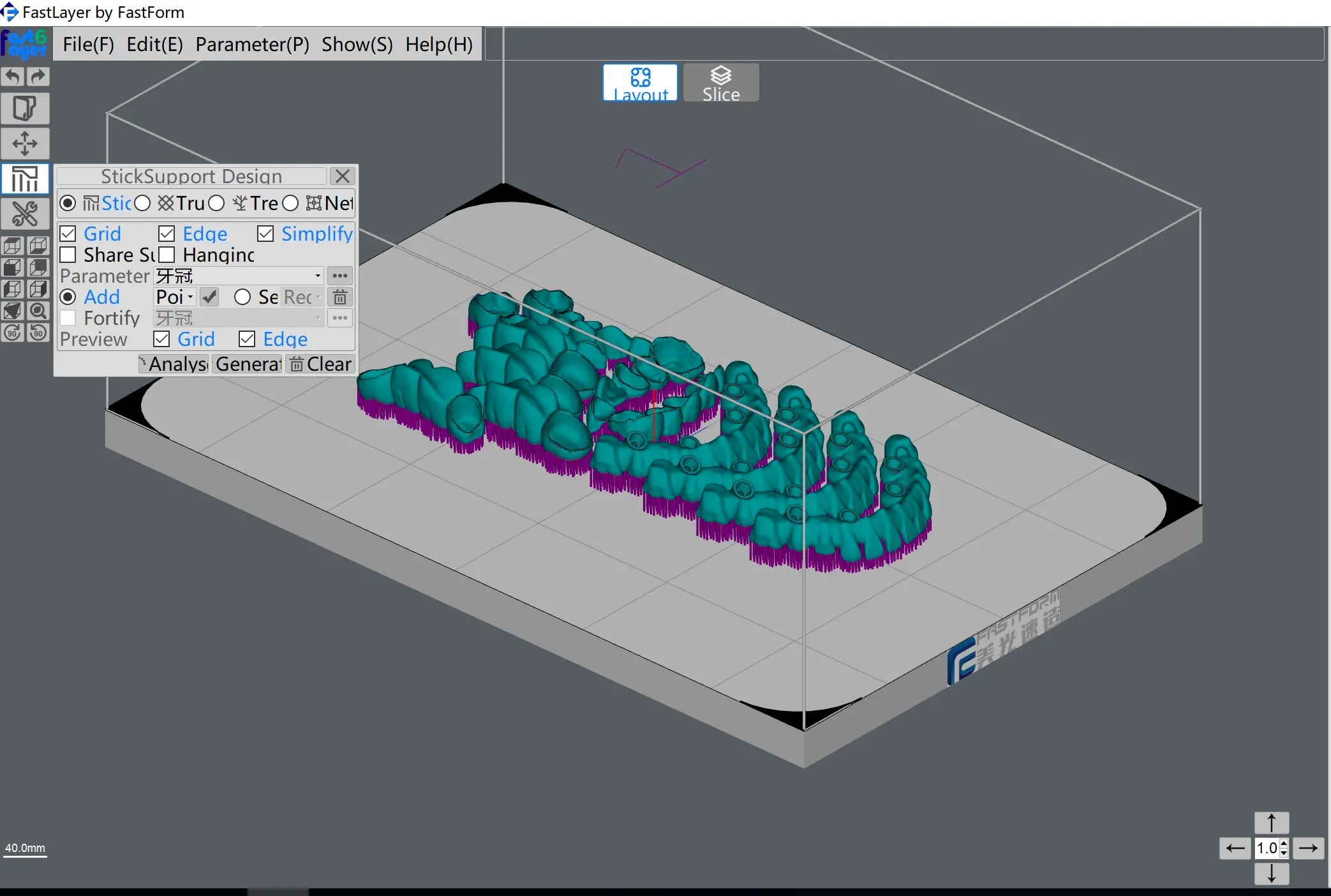

Software Features

- Fastlayer Software

3D cutting software developed over 8 years enables automatic programming of precision dental and industrial designs.

Full layout and path planning with one click. Set the print platform size and refine any model.

SLM metal 3D printing is possible from the following supported formats: STL, OBJ, CAD, STEP, 3MF.

Integrates print parameter databases for many metal materials with independently developed precision parameter libraries for dental cobalt-chromium and titanium alloys.

Allows customers to develop and customize parameter functions themselves.

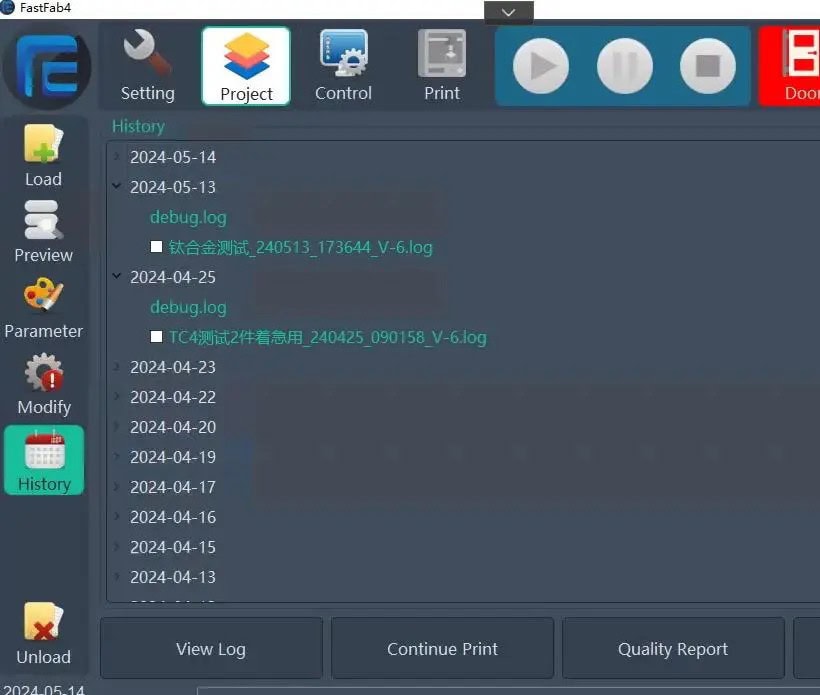

- FastFab

Intuitive user interface, well-structured layout and a range of tools and functions.

Convenient, efficient software process and simple controls allow users to easily perform tasks.

The software’s performance and responsiveness ensure smooth user experience.

It only takes 5-10 minutes to master.

All operational processes are performed step by step, without logical errors, saving time and printing quality.

Monitoring the printing process using a video camera

Print Log

Records all printing data in a log to facilitate the verification of all printing procedures.

Provide customer support through troubleshooting and analysis to improve the quality of metal powder printing.

Accessories

- Cleaning kit

- Silicone recoat blade

- Hardware hand tool

- Stainless steel base plate

- Other necessary tools and equipment

Auxiliary equipment

Supplementary equipment (purchased separately):

- Nitrogen generator

- Vacuum cleaner

- Sieving machine

- Powder drying oven

- Heat treatment furnace

- Sawing machine

- Explosion-proof vacuum cleaner

- Vacuum oven for heat treatment

- Sand blasting machine

After-sales service

- 24/7 English language remote service

- On-site assistance

Fastform FF-M220 specifications

| Printing Technology | SLM |

| Build Field (mm) | 220*140*100 |

| Layer Height (micron) | 20 – 50 |

| Laser Spot Size (mm) | 50~80 |

| Printing Accuracy (µm) | 50 |

| Maximum Scan Speed (mm/s) | 10 000 |

| Production Capacity | 2000 pieces/Year |

| Laser Characteristics | 500W, 2 lasers |

| Hopper Capacity (L) | 2,5 |

| Gas Supply | Ar / N₂ |

| Oxygen Content | ≤ 0,1% |

| Supported Materials | Cobalt-chrome, Titanium, Aluminum alloy, Stainless steel, Nickel alloy, Tool steel |

| Cooling System | Water cooling |

| Features | Equipped with a high-brightness laser source with high power density, which increases the printing speed while maintaining quality. Equipped with a Scanlab galvanometer with high accuracy, minimal drift and precise position control. |

| Supported File Types | STEP, IGES, SLC, CLI, STL |

| Operating System | Windows 10 |

| Software | Fastlayer, FastFab |

| Connectivity | WiFi |

| Power Requirements | Single phase 220V, 1,5 kW |

| Air Handling | Permanent filter, service life of at least 30,000 hours |

| Manufacturer Country | China |

| Warranty Period (months) | 12 |

| Certifications | CE, FDA |

| Weight Netto (kg) | 550 |

| Dimensions Netto (mm) | 1150*750*1800 |

Buy a 3D printer in Ukraine that can perform 3D metal printing

Ready to take your dental practice to the next level? Contact us today for a consultation and to learn more about the FastForm FF-M220.

Auxiliary equipment*

For a complete and safe metal 3D printing workflow, you may need additional equipment. We offer a wide range of accessories for FastForm 3D printers.

📌 For more information and assistance in choosing equipment, please contact your manager.

*Not included in the price of the printer.