- Stock: In Stock

- Product code: 00-00012978

- Shipping Weight: 720.00kg

Available Options

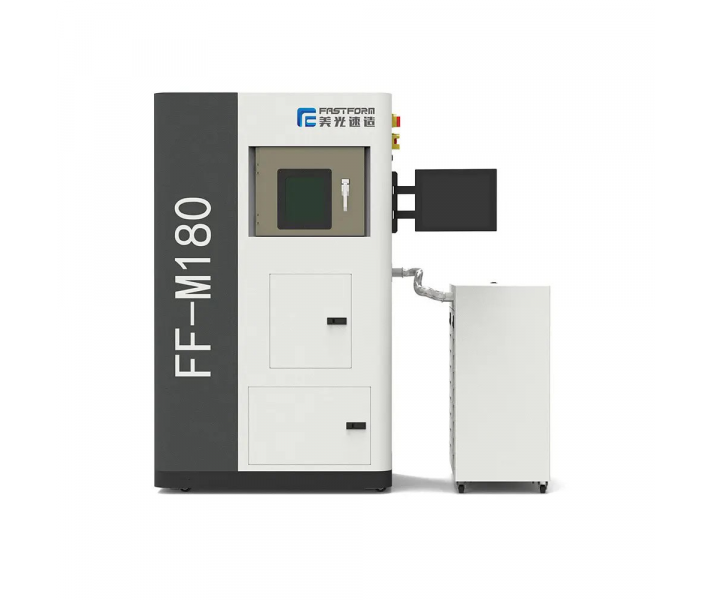

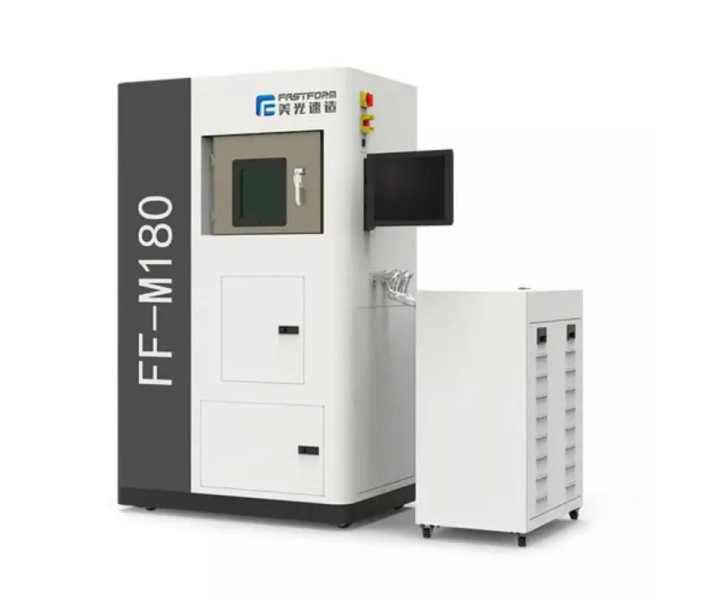

Dental Metal 3D Printer SLM FastForm FF-M180D

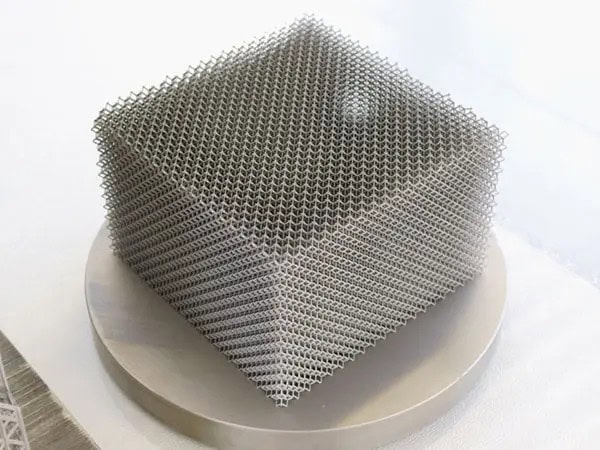

Metal 3D printer SLM Fastform FF-M180D is made for the mass production of unique high-precision elements in the dental industry. Thanks to the built-in dual laser source, which increases printing efficiency by more than 2 times, this 3D printer is capable of processing large volumes of orders with high accuracy.

The printer is available in two versions

- Basic configuration: diameter 180 mm * height 100 mm, 1 laser 500 W

- Additional configuration: diameter 180 mm * height 100 mm, 2 lasers of 500 W each

Metals for 3D printing on FF-M180D

Metals and alloys in powder form:

- Cobalt-chrome

- Titanium

- Aluminum alloy

- Stainless steel

- Nickel alloy

- Tool steel

High-performance metal 3D printing

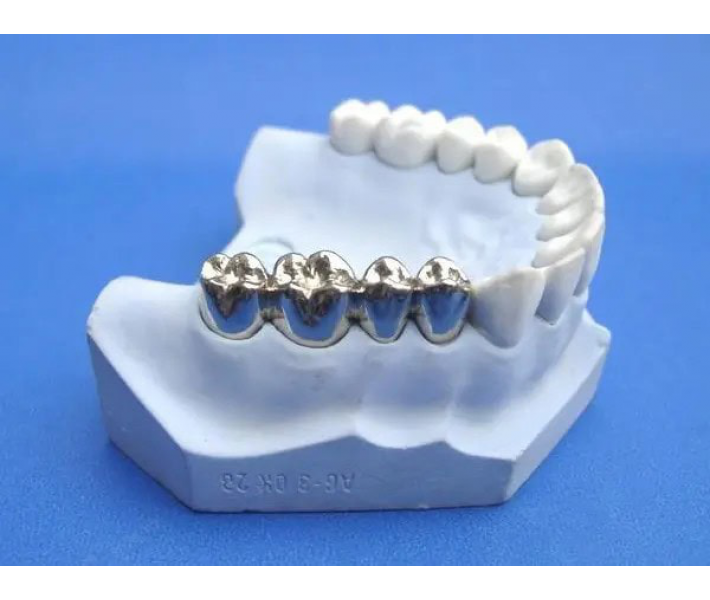

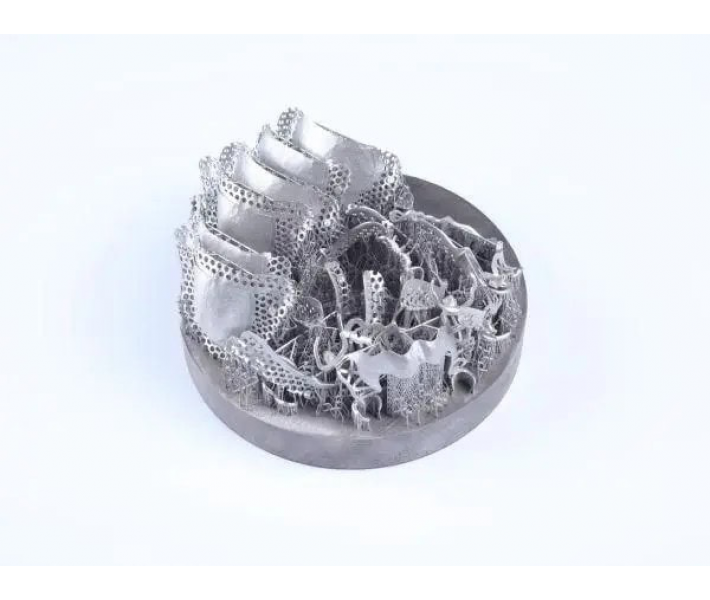

The FF-M180D features a large base plate that can print up to 300-320 teeth or 25 frames at a time. The use of CoCr metal powder, titanium, and integration with the Fastform printing program database make this printer a versatile tool for modern dentists.

Advanced technology creates impeccable quality

- High-brightness laser source. Provides high power density, which allows for increased printing speed without loss of quality.

- High-precision Scanlab galvanometer. Guarantees precise position monitoring and stability of the printing process.

- Laser melting in a powder bed. The use of laser sintering technology ensures high quality and precision of printing.

In-house developed software

Automatic print profile. Start printing with one click. Special print profiles for dentistry.

Productive Metal 3D Printing with FastForm FF-M180D

2*500W CW fiber laser source, high-brightness and high-power density laser beam output, greatly saving power consumption with beam quality of M^2 ≤ 1.15.

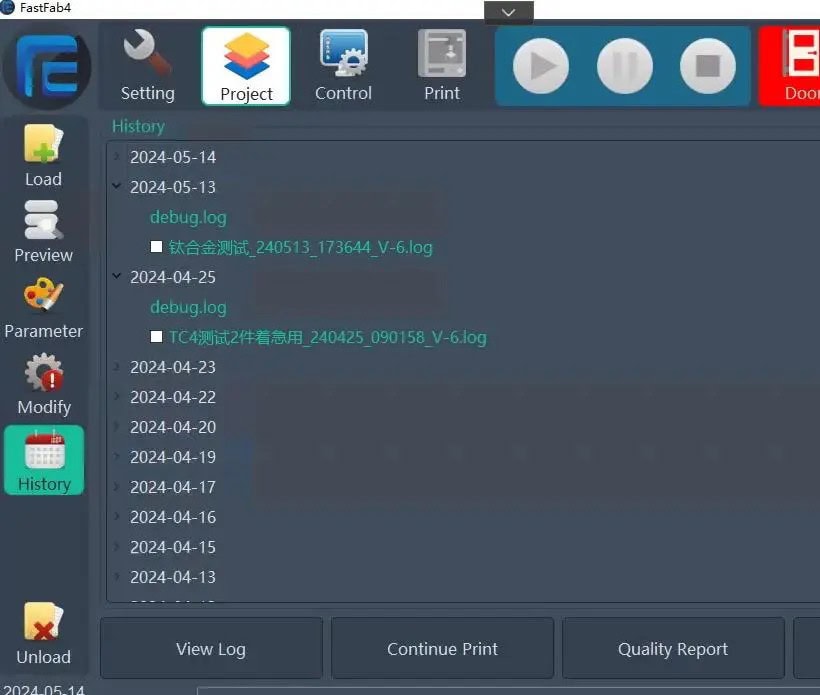

Innovative Software

- Fastform. After 8 years of R&D, the 3D cutting software is automatically programmed for precise dental and industrial design.

- Fastlayer. Complete layout and path planning with one click. Support all types of 3D printing files (STL, OBJ, CAD, STEP, 3MF).

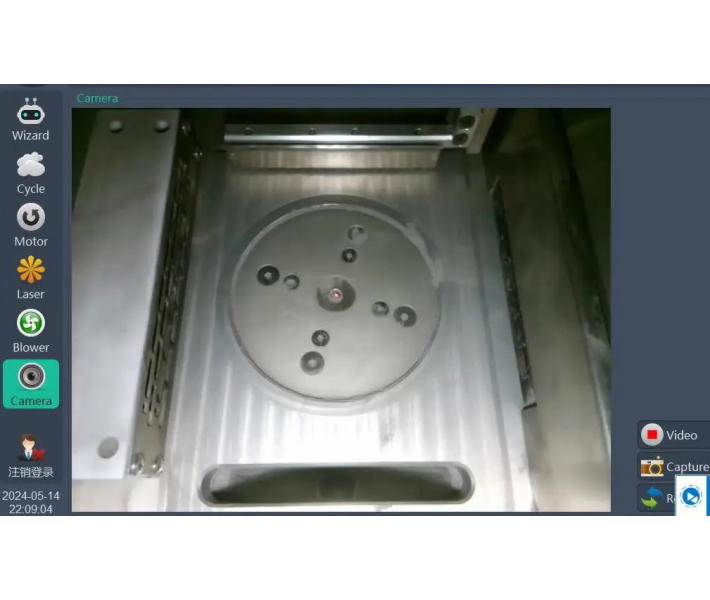

- FastFab. The intuitive interface allows users to easily get started and complete their tasks.

Ease of Use

Simple interface, streamlined workflow and clear controls allow you to set up the printing process in 5-10 minutes. The built-in camera helps you monitor the printing process without the risk of laser radiation.

Metal 3D Printing Samples

Metal 3D printing SLM FF-M180D: Security and Control

- Print Logs

Save all process data, allowing you to easily check and analyze your print programs. Helpdesk provides analysis and troubleshooting to improve print quality.

Built-in video camera

Integration of a video camera allows you to control 3D printing without the risk of laser radiation.

Accessories and spare parts

- Cleaning kit

- Silicone blade for recoating

- Hardware hand tool

- Stainless steel base plate

- Other necessary tools and accessories

Auxiliary equipment (purchased separately)

- Nitrogen generator

- Vacuum cleaner

- Sieving machine

- Powder drying oven

- Heat treatment furnace

- Sawing machine

- Explosion-proof vacuum cleaner

- Vacuum oven for heat treatment

- Sand blasting machine

After-sales service

- 24/7 English language remote service

- On-site assistance

Fastform FF-M180D specification (List view)

- Printing Technology: SLM

- Build Field: D180 * H100 mm

- Layer Height: 20 – 50 micron

- Laser Spot Size: 0.05 – 0.08 mm

- Printing Accuracy: 50 µm

- Maximum Scan Speed: 0 – 7 m/s

- Laser Characteristics: 500W * 2 (Dual Laser)

- Hopper Capacity: 6 L

- Gas Supply: Ar / N₂ (Argon / Nitrogen)

- Oxygen Content: ≤ 0.1%

- Supported Materials: CoCr, titanium alloy, pure titanium, aluminum alloy, nickel alloy, stainless steel, etc.

- Cooling System: Water cooling

- Features: Resume printing after power failure, Automatic power off, Top powder feed

- Supported File Types: STL, OBJ, CAD, STEP, 3MF

- Operating System: Windows 10

- Software: Fastlayer, FastFab

- Connectivity: WiFi

- Power Requirements: 220V 50Hz

- Air Handling: Permanent filter, service life of at least 30,000 hours

- Manufacturer Country: China

- Warranty Period: 12 months

- Certifications: CE

- Weight Netto: 550 kg

- Dimensions Netto (L×W×H): 1140 × 1180 × 1900 mm

Buy in Ukraine FastForm FF-M180D printer, performing metal 3D printing

SLM printer FastForm FF-M180D is an ideal solution for the dental industry. It combines high productivity, accuracy and ease of use. It prints a wide range of metal alloys, opens up new possibilities for mass production of metal dental products, ensuring consistent quality and efficiency.

Auxiliary equipment*

For a complete and safe metal 3D printing workflow, you may need additional equipment. We offer a wide range of accessories for FastForm 3D printers.

📌 For more information and assistance in choosing equipment, please contact your manager.

*Not included in the price of the printer.