- Stock: In Stock

- Product code: 00-00013290

- Shipping Weight: 4.50kg

- SKU: 21010

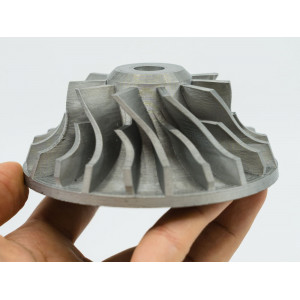

Markforged H13 Tool Steel Filament – Tool Steel for the Most Complex Tasks

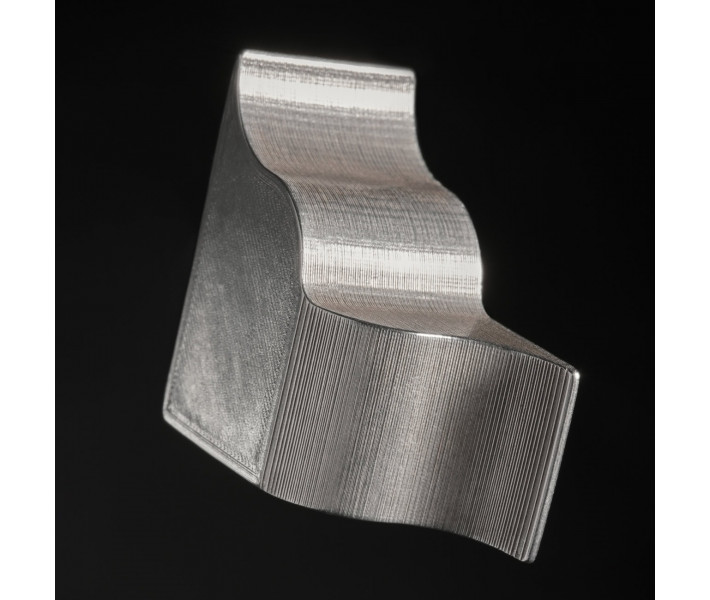

Markforged H13 Tool Steel filament is a high-quality material that opens new possibilities in the field of tool manufacturing, equipment, and parts with enhanced strength. Thanks to its unique characteristics, H13 surpasses even stainless steel 17-4 PH, demonstrating resistance to high temperatures and retention of properties during sudden changes in operating conditions.

Main Characteristics of the Material

This Markforged H13 Tool Steel filament can be heat-treated, allowing for hardness ratings of up to 45 HRC and a tensile strength of 1680 MPa. In its "as-sintered" state, the hardness is 40 HRC, and the strength is 1540 MPa.

- hardness – 40 HRC (as-sintered), 45 HRC (after heat treatment)

- tensile strength – 1540 MPa (as-sintered), 1680 MPa (after heat treatment)

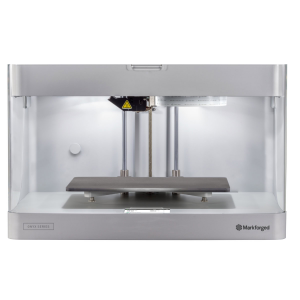

- compatibility – Metal X™ system

- format – H13 Tool Steel 400cc (400 cm³ spool)

Why Choose H13 Tool Steel for 3D Printing?

Unlike other metal materials, H13 tool steel for 3D printing combines high hardness, abrasion resistance, and thermal shock resistance. This makes it an ideal choice for tools and parts that operate under high loads and sudden temperature fluctuations.

Key Advantages:

- ability to be used in the production of tools for hot stamping and molds

- high wear resistance, increasing the lifespan of parts

- excellent machinability after printing and heat treatment

Areas of Application

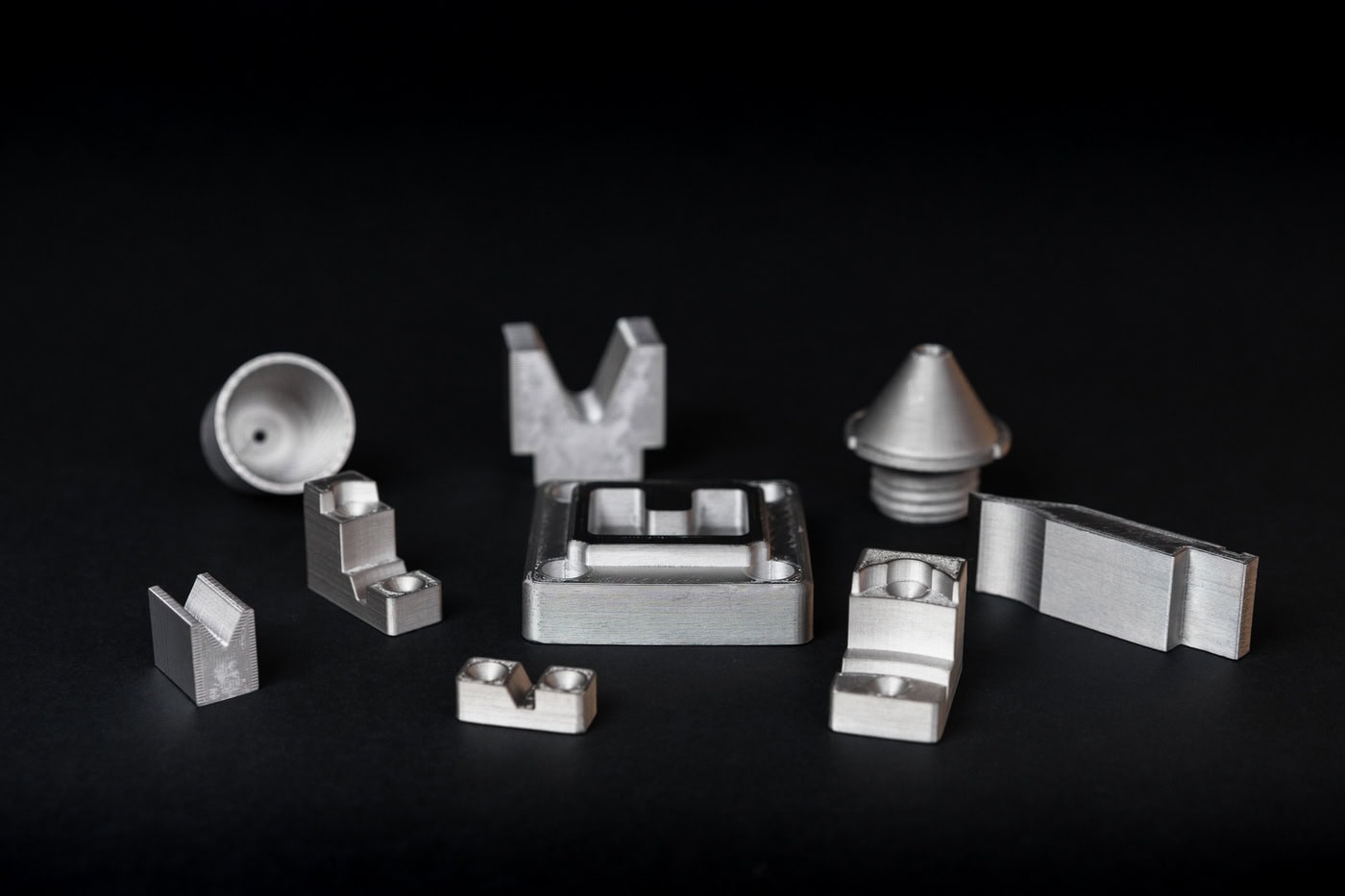

The H13 Tool Steel 400cc filament is used in the production of:

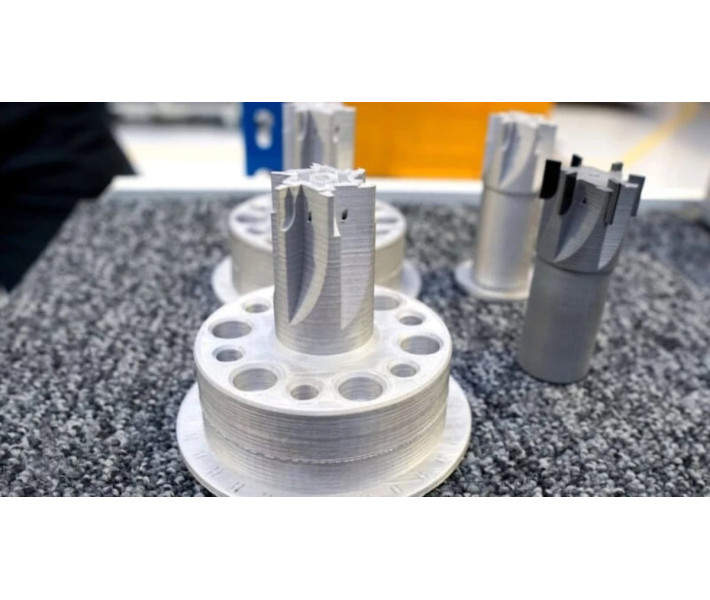

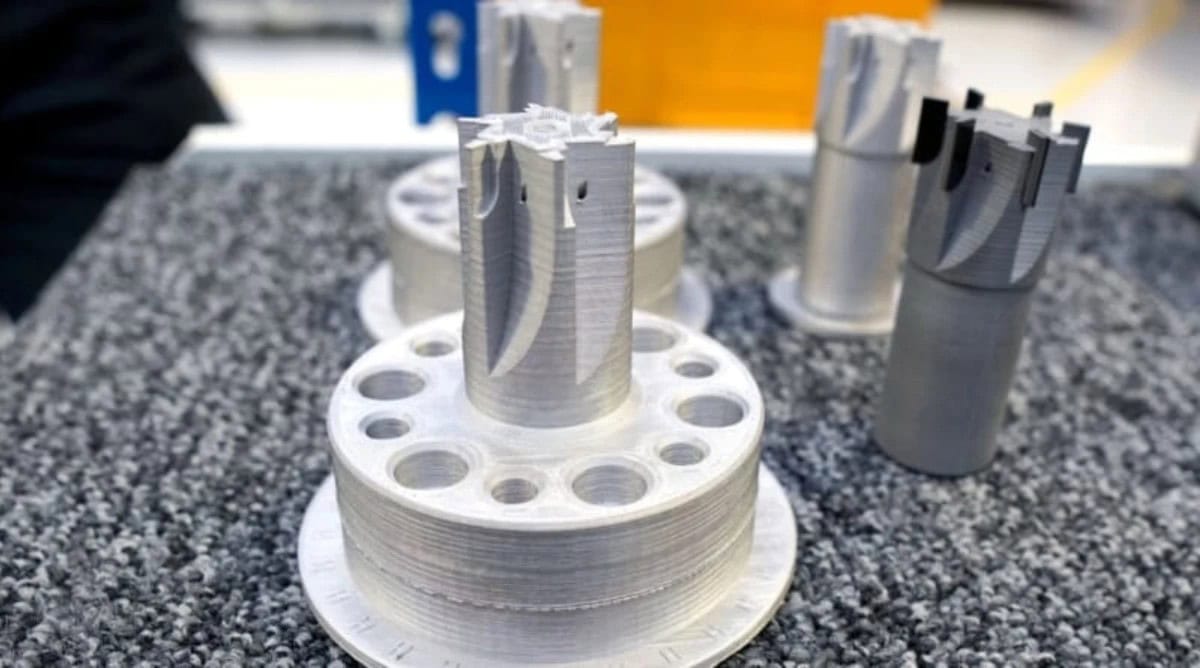

- cutting tool bodies

- soldering and welding devices

- inserts for molds

- dies, punches, and tooling

- wear-resistant tools

- parts that operate at high temperatures

Thus, the material for manufacturing tools via 3D printing opens up wide opportunities for industrial enterprises seeking to enhance the efficiency and reliability of production processes.

Heat Treatment Features

3D printing with tool steel allows for the production of blanks that can subsequently be brought to the desired properties through heat treatment. Recommended conditions:

- air hardening at 1010°C (1850°F)

- double tempering at 600°C (1110°F)

- to increase hardness (while reducing toughness) – tempering at 500–550°C (930–1022°F)

This process allows for the optimization of steel characteristics depending on specific product requirements.

Why Choose Markforged H13 Tool Steel Filament?

Companies in the fields of machine engineering, metalworking, and tool manufacturing use this filament to create products that combine durability and precision. It allows for the production of parts that withstand high loads, sharp temperature fluctuations, and intense wear.

This material meets the demands of modern manufacturing, where quality and stability of results are crucial.

Markforged H13 Tool Steel filament is the solution for those seeking a reliable, strong, and heat-resistant material for industrial 3D printing. With compatibility with Metal X and the possibility of heat treatment, it is ideal for creating tools, equipment, and parts that operate in extreme conditions.

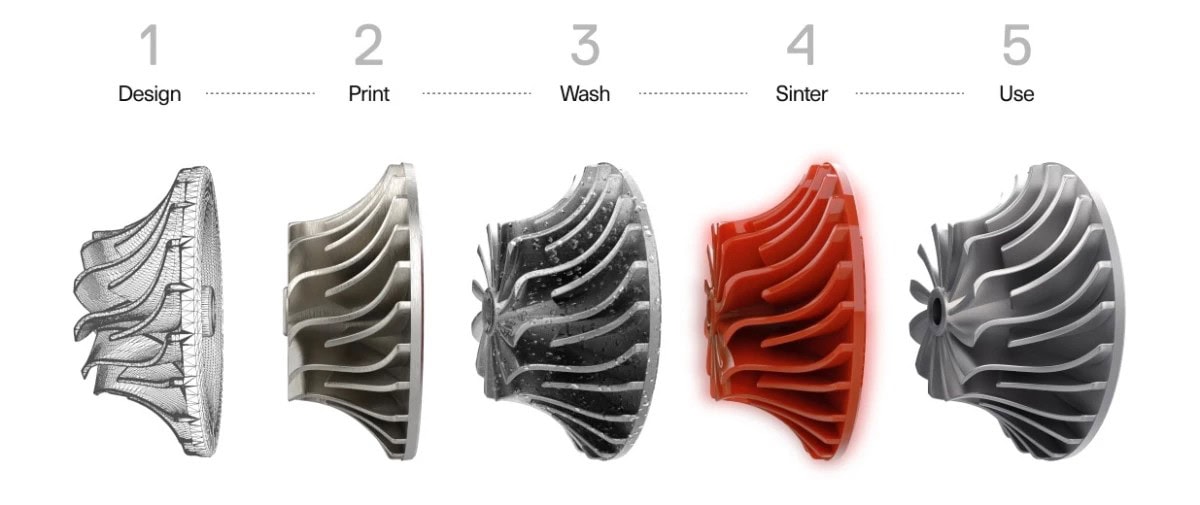

ADAM Manufacturing Technology

The process of manufacturing parts from this material is based on the ADAM (Atomic Diffusion Additive Manufacturing) additive manufacturing technology. The essence of the technology is that stainless steel powder is contained in a polymer binder, which is fed into the nozzle based on the principles of classic FDM printing. The subsequent sintering process leads to atomic diffusion, resulting in a fully metal part with excellent mechanical properties.

Buy Markforged Copper Filament in Ukraine

Choose Markforged H13 Tool Steel filament at 3DDevice – the official representative of Markforged in Ukraine.

Since 2012, we have specialized in additive technologies, providing expert consultations and assistance in material selection. Our experience and support will help you achieve maximum efficiency in production.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.