- Stock: Price on request

- Product code: 00-00013601

- Shipping Weight: 31.20kg

DELFIN MTL 301 1/2 D: A Revolutionary Solution for Modern Manufacturing

Modern industrial enterprises require equipment that combines efficiency, reliability, and versatility. DELFIN MTL 301 1/2 D stands out as an optimal choice for companies seeking to enhance productivity without compromising quality.

This machine represents an innovative approach to material processing, ensuring high precision and process stability. Its adaptability makes it suitable for various industries, from mechanical engineering and metallurgy to the production of complex components for machinery and industrial design.

Key Advantages of DELFIN MTL 301 1/2 D

Enhanced Productivity

The DELFIN MTL 301 1/2 D streamlines manufacturing processes, reducing processing time and allowing companies to increase output without additional resources.

Reliability and Consistency

Designed for long-term operation without interruptions, this equipment ensures stable performance even under demanding industrial conditions.

Seamless Integration

The system can be easily integrated into existing production lines and workflows, minimizing downtime and facilitating quick adaptation for staff.

Versatility

DELFIN MTL 301 1/2 D is suitable for a wide range of materials and products, making it a universal solution for companies with diverse production needs.

Resource Efficiency

With optimized energy consumption and efficient material usage, companies can reduce operational costs while maintaining high-quality output.

Why Choose DELFIN MTL 301 1/2 D

- Professional Reliability: Built for continuous industrial use.

- Innovative Technology: Advanced solutions ensure precision and stable processing.

- Guaranteed Results: Delivers high-quality products without extra time or effort.

- Support and Service: Comprehensive manufacturer support and consultancy for effective use.

Applications

- Mechanical Engineering – precise component processing.

- Metallurgy – reliable operation with various materials.

- Technical Component Manufacturing – capable of handling complex designs.

- Industrial Design – meets modern standards for precision and quality.

Specifications

| Parameter | Specification |

|---|---|

| Atex zone | Haz. location (20 Int/21 Ext) |

| Marking | II 1/2D Ex h tb IIIC T80°C (Int) / T95°C (Ext) Da/Db |

| EX Category | EX 21 1/2D |

| Use | Dust |

| Power | 1,1 kW |

| Current draw | 8 A |

| Max waterlift | 2250 mmH₂O |

| Max airflow | 215 m³/h |

| Suction inlet | 50 mm |

| Voltage | 115/230 V – 50/60 Hz |

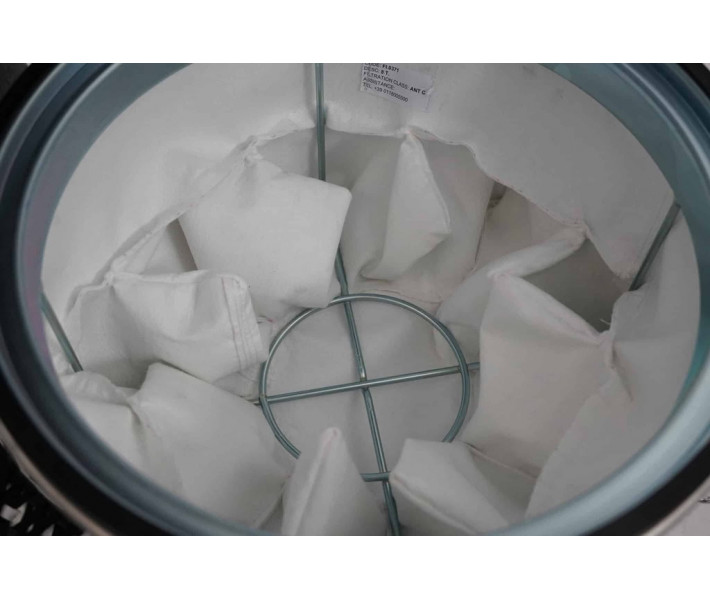

| Capacity | 40 L |

| Collection tank | AISI304 |

| Noise level | 74 dB(A) |

| Dimensions | 44 × 42 × 84 cm |

| Weight | 26 kg |

| Primary filter | Star / Tasche |

| Media, class | Polyester - ANT M |

| H/HEPA filter | Standard |

| Filter surface | 11.000 cm² |

| Filter grade | H14 with 99,995% efficiency on MPPS method |