- Stock: In Stock

- Product code: 00-00000096

- SKU: FS1-SIFT-230V

- Description

- Characteristics

- Fuse Complete Service Plan

- Choose Fuse 1+ Package

- Fuse Sift 3D Tour

- Reviews

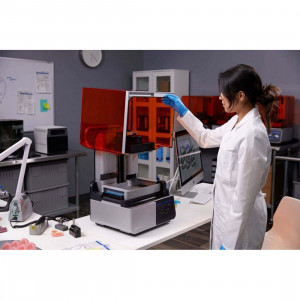

Fuse Sift – powder recovery station for Formlabs Fuse SLS 3D printer

Fuse Sift for Fuse 1 is a safe and efficient nylon powder collection system for the Formlabs Fuse 1 and Fuse 1+ 30W 3D printers.

This universal station will help you to conveniently and safely cope with many tasks in production using SLS technology:

- remove the printed parts from the unused powder,

- collect and refresh this unspent powder,

- store and mix powder in one freestanding device.

Fuse Sift will help you conveniently, functionally and compactly organize the processing of bulk nylon in one SLS powder processing device.

With the optional Fuse Sift Glovebox Panel, you can completely contain powder and enable faster parts extraction.

How does it works? Formlabs Fuse 1 Ecosystem

After printing is complete, you need to move the build chamber to the Fuse Sift. This safe and efficient powder recovery station makes your workflow perfect. It automatically doses and mixes used and new powder in the ratio you set on the display.

The device is equipped with a negative air pressure system that keeps the powder inside. Powder from the cooking chamber will not enter your work area. Plus, this gives you open access under the hood and easy cleaning of parts with the built-in vacuum hose.

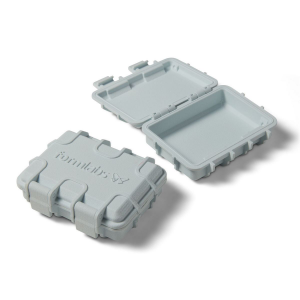

By reusing the powder, you will reduce waste with a 30% material renewal rate. Fuze Sift filters out particles, which are then mixed with new powder and used in future prints. Thus, up to 70% recycled powder can be used for printing. After transferring the build chamber to Fuse Sift at the end of printing, install a new build chamber in Fuse 1 so as not to interrupt the printing process.

No other SLS system on the market today provides this level of functionality from a single device.

Specifications Fuse Sift

| Printer Compatibility | Fuse 1 |

| Dimensions | 991 × 610 × 1888 mm |

| Assembly chamber dimensions | 279 × 342 × 489 mm |

| Screening weight of fuses | 93 kg |

| Assembly chamber weight | 11 kg (17,6 kg, заполнено 20% порошка) |

| Air filtration technology | Replacement HEPA filter |

| Build volume | 16,5 x 16,5 x 30,0 cm (rounded corners) |

| Hopper capacity for fresh powder | 10.7 kg Nylon 12 |

| Hopper capacity for used powder | 9.8 kg Nylon 12 |

| Working environment | 18 – 26 ºC |

| ≤ 30% ambient humidity | |

| Air treatment | Negative pressure hood with replaceable HEPA filter. |

| Independent ventilation system | |

| Air filtration | Replaceable HEPA medium |

| Power Requirements | At a vacuum of less than 6A (230 VAC) / 12A (120 VAC): |

| EU: 230 VAC, 7.5 A (dedicated circuit) | |

| With a vacuum of more than 6A (230 VAC) / 12A (120 VAC): | |

| EU: 230 VAC, 10 A (dedicated circuit) | |

| Vacuum requirements | Auxiliary vacuum with static dissipative components that is grounded and bonded (e.g., NFPA 652 compliant vacuum) |

| Connection | Wi-Fi, Ethernet, USB 2.0 |

| Sound emission | Does not exceed 76.5 dB |

| Filter fuse control | Interactive touch screen, physical buttons |

| Accessories included | Large brush |

| Small brush x 2 | |

| Chimney sweeps | |

| Dental selections | |

| Gloves | |

| Respirator | |

| Safety glasses | |

| Vacuum Brush Tool | |

| Vacuum slotted tool | |

| Lifting belts |

Fuse 1: Highly efficient selective laser sintering is finally available:

Fuse Series Complete Service Plan Benefits

The Fuse Series Complete Service Plan is designed for maximum peace of mind with private remote training to get you started, direct phone and email support, as well as preventative checkups to keep you printing, and rapid repairs by Certified SLS Experts to resolve any major issues.

| Coverage | Each Plan includes support for one Fuse Series printer, one Fuse Sift and one Fuse Blast |

| Warranty | One, two, three or five years |

| Printer/Component Replacement | ✔ |

| Direct Phone Supoport | ✔ Mon - Fri, 9 am - 6 pm ET and CET. Multilingual support in English, German, French and Italian. |

| Annual Preventable Checkups | ✔ An annual onsite visit from a trained expert to perform routine maintenance. |

| Training Videos & Live Q&A | ✔ Schedule a live session with a Pro Service Expert to ask questions about your specific workflow. |

| Onsite Repairs | ✔ |

| Fleet Pricing | ✔ Discounts available for co-located printers |

Eliminate the Unexpected

Maximize your return, protect your investment, and eliminate unexpected costs with our service plan for Fuse Series SLS 3D printers, Fuse Sift, and Fuse Blast.

Worry-free warranty coverage and repairs

Our team will work with you to quickly resolve any issues through remote support, including shipping replacement parts free of charge. If we determine that an onsite visit is necessary, Formlabs or your certified local partner will send a Certified SLS Expert to your facility at no extra charge.

Up to five years of coverage for your entire fleet

The Fuse Series Complete Service Plan offers one, two, three, or five years of support that can be renewed at your discretion. Purchase more years upfront for additional savings.

Priority phone and email support

Priority phone and email access to our team of dedicated experts.

Annual preventative checkups

Get an annual onsite visit from a trained expert to perform routine maintenance so you can stay focused on running your business.

Training videos and a live Q&A

Watch our onboarding videos to get started and schedule a live Q&A with one of our experts to answer any questions about your workflow or applications.

Onsite training available to purchase

Get to know your printer and post-processing on your home turf with a customized training session defined by your needs, enabling you and your team to become SLS experts in no time.

Terms and conditions apply. Please see the Formlabs Fuse Series Service Plan Terms of Service for more information.

Build Your Own Package |

Starter Package |

Complete Package |

High Efficiency Package |

|

| Fuse 1+ 30W Printer 230V (including Build Chamber) | ✔ | ✔ | ✔ | ✔ |

| Fuse Build Chamber 230V | ✔ | ✔ | ||

| Fuse Powder Cartridge | ✔ | 2 ✔ | 2 ✔ | |

| Fuse Depowdering Kit Workspace and Tools | ✔ | |||

| Fuse Depowdering Kit Sifter (230V) with 150 Sieve | ✔ | |||

| Fuse Series Printer Stand | ✔ | ✔ | ||

| Fuse Sift 230V | ✔ | ✔ | ||

| Fuse Blast | ✔ | ✔ | ||

| Fuse Blast Polishing Module | ✔ | |||

| Fuse Blast Polishing Media 4 L (2.5 kg) | 2 ✔ | |||

| Fuse Blast Polishing Agent 115 mL | ✔ | |||

| Fuse Blast Polishing Mesh | ✔ | |||

| Nylon 12 Powder 10 kg | 4 ✔ | |||

| Industrial Vacuum 230V | ✔ | |||

| PreForm Software | ✔ | ✔ | ✔ | ✔ |

| Fuse Series Complete Service Plan for 1 year | ✔ | ✔ | ✔ | ✔ |

| Fuse Series Complete Service Plan* for 3 or 5 years | Optional | Optional | Optional | Optional |

* Maximize your return, protect your investment, and eliminate unexpected costs with Formlabs Fuse 1+ 30W and

Fuse Sift Service Plans.

Maximum peace of mind with Fuse Series Complete Service Plan

The Fuse Series Complete Service Plan is designed for maximum peace of mind with private remote training to get you started, direct phone and email support, as well as preventative checkups to keep you printing, and rapid repairs by Certified SLS Experts to resolve any major issues.

- Worry-free warranty coverage and repairs

- Up to five years of coverage for your entire fleet

- Priority phone and email support

- Annual preventative checkups

- Training videos and a live Q&A

- Onsite training available to purchase