Formlabs Form 2 Build Platform

Price Incl. VAT

Formlabs Authorized Partner

3DDevice is an Authorized Partner of Formlabs in Ukraine

- Stock: In Stock

- Product code: 00-00001152

- SKU: BP-F3-01

Based on 0 reviews.

-

Write a comment

₴5 881.00

Ex Tax: ₴5 881.00

Quantity:

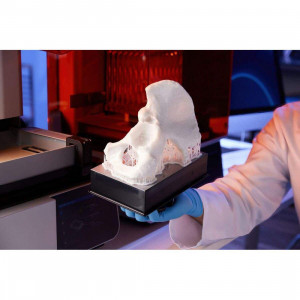

Build Platform

The Build Platform for Form 2 can accelerate your workflow, whether you are changing resin or starting a new print while removing your part from another platform.

SLA Printing

Here's how the SLA manufacturing process works:

- The Form 2 build platform is initially placed in a tank of liquid photopolymer, one layer height away from the liquid surface.

- Then, the UV laser creates the next layer by selectively curing and hardening the photopolymer resin. The laser beam is focused on a specified path using a set of mirrors. The entire cross-sectional area of the model is scanned, so the resulting part is completely solid.

- When the layer is finished, the platform moves to a safe distance, and the machine's laser re-coats the surface. The process then repeats until the part is complete.

- After printing, the part is not fully cured and requires further post-processing under ultraviolet light if very high mechanical and thermal properties are needed.

- The liquid resin hardens through a process called photopolymerization: during curing, the carbon chains of the monomer that make up the liquid resin are activated by the ultraviolet laser and become solid, creating strong unbreakable bonds between them. The photopolymerization process is irreversible, and there is no way to convert SLA parts back to liquid form: when heated, they will burn rather than melt. This is because the materials produced with SLA are made from thermosetting polymers, unlike the thermoplastics used by FDM.

3D Printing

Printing Technology

SLA

Details

Printer Compatibility

Form 2

Country of Brand Registration

USA