- Stock: In Stock

- Product code: 00-00013576

- Shipping Weight: 5.50kg

- SKU: RS-RPS-FL80-01

High-Volume Production with Formlabs Flexible 80A Resin Form 3, 5L

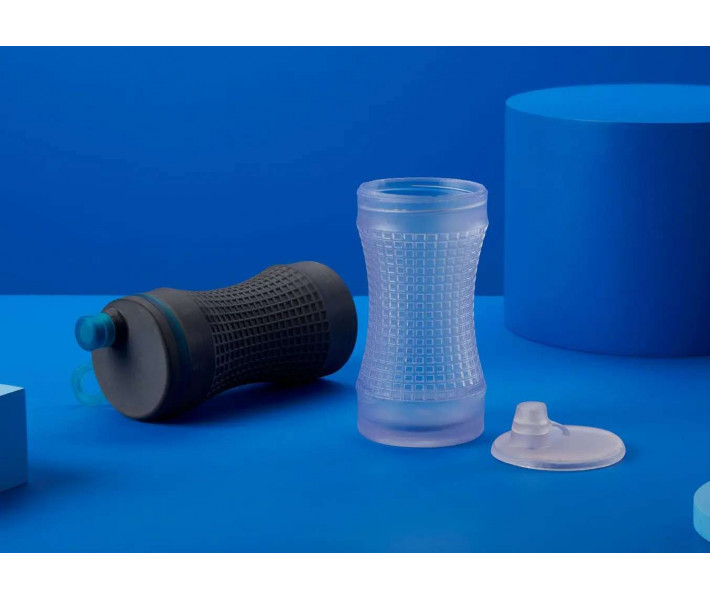

The Formlabs Flexible 80A Resin Form 3, 5L container is the ultimate solution for scaling up production and streamlining workflows on Form 3 generation printers. Designed specifically for use with the Formlabs Resin Pump system, this large-format canister enables automated resin dispensing, allowing for continuous, unattended printing. This material stands out as a stiff, soft-touch elastomer with an 80A Shore durometer, making it the ideal choice for prototyping rubber-like parts. It combines the flexibility of TPU with the high-resolution surface finish characteristic of stereolithography (SLA), offering a translucent finish that mimics the mechanics of harder rubber compounds.

Industrial Rubber Simulation

Parts fabricated using Flexible 80A Resin are engineered to endure significant mechanical stress, including bending, flexing, and compression. Unlike standard resins that may snap under pressure, this advanced formulation allows components to undergo repeated cycles and slowly return to their original shape without structural failure. This capability allows businesses to bring the production of flexible parts in-house, replacing slow and costly outsourcing or molding processes with rapid, on-demand manufacturing.

Durability and Clarity

The material excels in creating objects that are both soft and strong, capable of stretching and compressing without cracking. The inherent transparency of the resin provides a clear view into the internal mechanics of a model, which is invaluable for fluidics or complex assemblies. Whether you are creating ergonomic grips that require a soft-touch feel or functional seals and gaskets, Formlabs Flexible 80A Resin ensures your prototypes look and perform like the final mass-produced product.

Versatile Applications

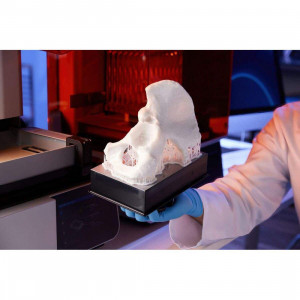

This elastomer is highly versatile and suitable for a wide array of engineering and medical applications. It is frequently used for manufacturing cushioning, damping elements, and shock absorbers where impact resistance is key. Additionally, its biomechanical properties make it an excellent material for printing anatomical models, such as cartilage, tendons, and ligaments. To achieve optimal material properties, standard post-processing including washing in alcohol and UV post-curing is required to transition the parts from a green state to fully finished, durable components.

Technical Characteristics

- Material Properties: Flex 80A Resin simulates durometer rubber, offers high impact resistance and compression, and is great for ergonomic soft-touch grips.

- Requirement: 5L Container requires a Resin Pump to work.

- Application: Engineering, Prototyping, Medical Modeling.

- Print technology: SLA.

- Type: Translucent.

- Ultimate Tensile Strength: 8.9 MPa.

- Stress at 50% Elongation: 3.1 MPa.

- Stress at 100% Elongation: 6.3 MPa.

- Elongation at Break: 120%.

- Tear Strength: 24 kN/m.

- Hardness Shore A: 80A.

- Recommended lifetime/shelf life: 24 months.

- Compatible Printers: Form 2, Form 3/3+, Form 3B/3B+, Form 3L/3BL.

- Compatible Resin Tanks: Form 2 LT, Form 3 Tank (all), Form 3L Tank (all).

- Layer Thickness (Form 2): 50, 100 microns.

- Layer Thickness (Form 3/3B/3+/3B+): 50, 100 microns.

- Layer Thickness (Form 3L/3BL): 100 microns.

Buy Formlabs Flexible 80A Resin at 3DDevice

To ensure you receive genuine consumables and professional support, we recommend purchasing Formlabs Flexible 80A Resin Form 3, 5L from the 3DDevice online store. We are experts in additive manufacturing with experience dating back to 2012, ready to assist you in selecting the right materials for your specific engineering challenges.

As an official representative of Formlabs, 3DDevice guarantees the best prices on the market, official warranty coverage, and qualified service support. Our team provides comprehensive advice before, during, and after your purchase to ensure your production runs smoothly. Trust the professionals to keep your 3D printing workflow efficient and reliable.