- Stock: In Stock

- Product code: 00-00013591

- Shipping Weight: 5.50kg

- SKU: RS-RPS-CTBL-01

Optimize your digital dentistry workflow with the high-capacity Formlabs Custom Tray Resin, 5L. This biocompatible material is specifically engineered for the rapid production of custom impression trays, ensuring precision for implants, dentures, crowns, and bridges. Designed for high-volume labs, this 5-liter container works seamlessly with Formlabs automation tools to deliver consistent, accurate results while significantly reducing labor time. By utilizing this material, dental professionals can ensure reliable, high-quality outcomes for every patient case.

Why Choose Custom Tray Resin?

Precision Meets Efficiency

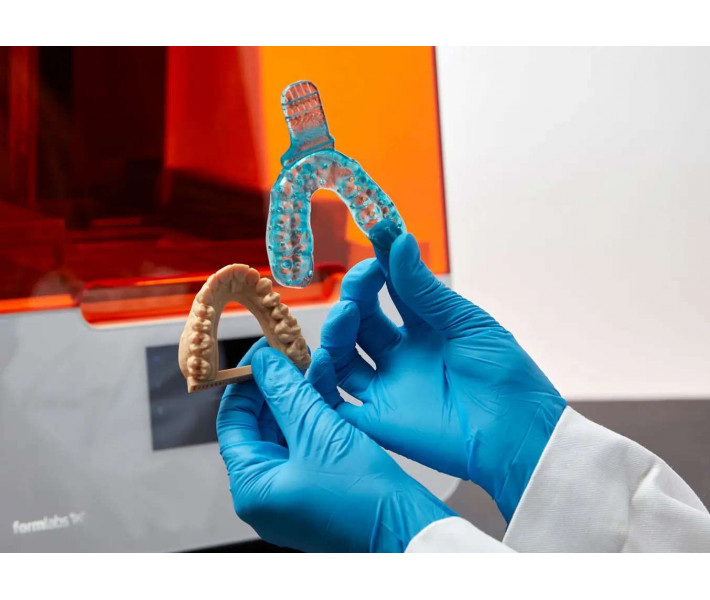

This resin is not just a printing material; it is a production-ready solution designed for creating highly accurate definitive impressions. Formlabs Custom Tray Resin, 5L enables high throughput by allowing full impression trays to be printed quickly using 200-micron layer heights. This speed significantly reduces labor time without compromising on quality. The material ensures that patient-matched trays are consistent and accurate, providing a solid foundation for digital workflows. Furthermore, its biocompatibility offers peace of mind to both clinicians and patients, making it an ideal choice for creating made-to-measure models for complex dental cases.

Applications

Versatile Dental Solutions

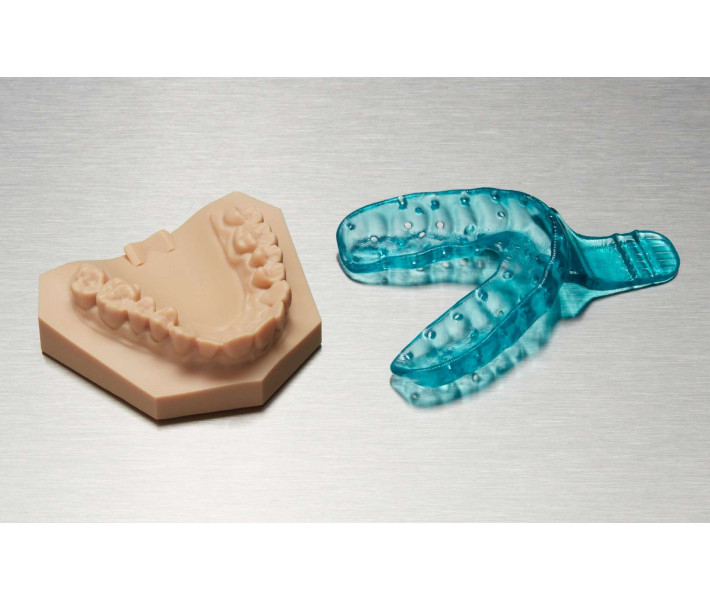

Leverage the advanced capabilities of Formlabs Custom Tray Resin, 5L to capture highly detailed anatomical data. It is the premier choice for taking accurate definitive impressions required for crown and bridge work, implants, dentures, and other comprehensive restorative cases. The primary application focuses on the fabrication of rigid, custom impression trays that fit the patient's dentition perfectly, ensuring superior clinical results.

Using Custom Tray Resin

Streamlined Digital Workflow

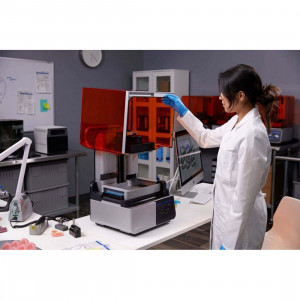

Formulated as a long-term solution for dental manufacturing, this material facilitates the even distribution of impression material, leading to more accurate impressions. The 5-liter format is specifically designed for use with the Resin Pumping System, enabling continuous production. By printing at 200 microns, labs can drastically cut down on production time while enabling higher throughput. When utilizing this material, it is essential to follow the specific application guides to ensure precise and accurate results for every appliance manufactured.

Required resources

Essential Equipment List

To achieve the best results with Formlabs Custom Tray Resin, 5L, specific hardware and software are required. Below is the list of necessary resources:

-

Made by Formlabs:

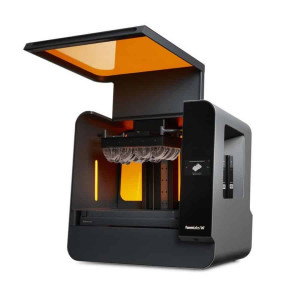

- Biocompatible Formlabs SLA printer (Form 2, Form 3B/3B+, Form 3BL, Form 4B, Form 4BL) with up-to-date firmware

- PreForm software (most recent version)

- Build platform

- Compatible resin tank (Form 2 LT, Form 3/3L Tanks, Form 4/4L Tanks)

- Custom Tray Resin (5L container requires Resin Pump)

- Form Wash or Finish Kit

- Form Cure

-

Made by third parties:

- Intraoral or desktop optical scanner

- Dental design software

- Low-speed dental handpiece with cutting and finishing wheels

- Polishing tools

- Isopropyl alcohol (IPA) ≥ 99%

Scan

Capturing Anatomical Data

The process begins with accurate data collection. To 3D print an impression tray, use a scanner to collect anatomical data of the patient’s dentition. You can either scan the patient directly using an intraoral scanner or utilize a desktop optical scanner to digitize a traditional polyvinyl siloxane (PVS) impression or stone model. This digital foundation is crucial for the subsequent 3D printing process.

Design

CAD Software Integration

Once scanned, the data is processed in a dental CAD software package to design the specific impression tray before printing. It is recommended to choose software that offers open STL file export to ensure compatibility. While specific design steps vary depending on the software package used, the goal is to generate a splint or tray file that is ready for PreForm. Contact your software provider for specific details on generating these files from patient scans.

Print feature recommendations

Optimized Design Parameters

For optimal structural integrity and performance, adhere to the following design specifications:

- Minimum wall thickness: 2 mm

- Minimum handle thickness: 3 mm

- For heavy impression materials, retention holes of at least 3 mm in diameter are recommended.

Preparing the Job

Before starting the print job, verify that you are using a compatible resin tank to prevent damage to your equipment. Install or update PreForm to the latest version, then set up your print job. Open your model, select the correct resin version and layer thickness, and orient the part to preserve fine details. Crucially, always orient parts with the intaglio surfaces facing away from the build platform. Note that for full compliance and biocompatibility, Formlabs Custom Tray Resin requires a dedicated resin tank, build platform, and Finish Kit that are not used with other resins.

Finish

Washing and Cleaning

Automated washing with the Form Wash ensures that parts are cleaned consistently by agitating the solvent bath and removing parts after a set time. Wash parts according to the specific time settings recommended for this material. Pay close attention to information affecting mechanical properties or biocompatibility. If the printed model is hollow or features internal channels, ensure that all liquid resin is thoroughly flushed out from these areas and allow parts to fully dry before post-curing.

Post-curing requirements

Achieving Mechanical Strength

To reach its optimal mechanical properties and ensure biocompatibility, the printed trays must undergo post-curing. Utilize the Form Cure with the recommended time and temperature settings specific to Formlabs Custom Tray Resin, 5L to ensure the final product meets all clinical standards.

Post-Processing

Finalizing the Part

Post-processing involves two critical steps: washing and curing. First, remove excess resin from the surface of the parts using an alcohol wash, either in a Formlabs-validated wash unit or an ultrasonic cleaner with Isopropyl Alcohol (IPA) ≥ 99%. Second, post-curing is necessary for biocompatible materials to achieve the safety standards determined by regulatory agencies. Always follow the material’s manufacturing guide and Instructions for Use (IFU) for proper post-processing procedures.

- Material Properties: Long-term biocompatible material for Custom Impression Trays

- Application: Dental

- Printing Technology: SLA

- Ultimate Tensile Strength: ≥ 70 MPa

- Young's Modulus: > 2500 MPa

- Elongation: > 3%

- Hardness Shore A: < 80A

- Recommended Lifetime/Shelf Life: 24 months

- Compatible Printers: Form 2, Form 3B/3B+, Form 3BL, Form 4B, Form 4BL

- Layer Thickness: 200 microns (Form 2, 3B series), 100 microns (Form 4B series)

Purchase Formlabs Custom Tray Resin, 5L from 3DDevice and benefit from our extensive expertise dating back to 2012. As an official representative of Formlabs, we guarantee the best prices on the market, full official warranty coverage, and comprehensive service support. Our team provides professional advice to help you choose the right materials and offers qualified technical support before, during, and after your purchase.