- Stock: In Stock

- Product code: 00-00013586

- Shipping Weight: 5.50kg

- SKU: RS-RPS-BMDU-01

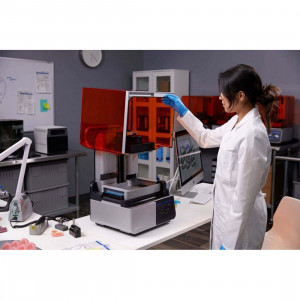

In the rapidly evolving field of medical manufacturing, safety and reliability are paramount. The Formlabs BioMed Durable Resin Form 3, 5L stands out as a premier material choice for creating transparent, biocompatible parts that demand exceptional toughness. Designed specifically for use with high-capacity SLA printers, this resin is engineered to withstand impact, shattering, and abrasion, making it indispensable for patient-specific instruments and medical devices. Please note that this large-format 5-liter container requires a specific Resin Pump for operation, ensuring a seamless and automated workflow for high-volume production environments.

Why Choose BioMed Durable Resin?

Medical Grade Innovation

Accelerate your healthcare manufacturing capabilities with a material built for high performance. Formlabs BioMed Durable Resin Form 3, 5L is specifically formulated to drive innovation, allowing for the rapid production of end-use devices where biocompatibility is non-negotiable. Manufactured in an FDA-registered, ISO 13485 certified facility, this material meets strict USP Class VI standards. It is suitable for long-term skin contact (over 30 days) as well as short-term contact with mucosal membranes, tissue, bone, and dentin, ensuring compliance and safety in critical applications.

Unmatched Durability

When mechanical strength is critical, this material delivers exceptional results. It allows engineers to produce medical-grade components that are highly resistant to impact and shattering, boasting a Notched Izod rating of 98 J/m. Beyond its physical toughness, the resin offers excellent clarity and a superior surface finish. Parts printed with this material look and feel like finished end-use products, providing both the aesthetic quality and the tactile properties required for professional medical settings.

Applications

Versatile Medical Solutions

Transform patient care by introducing cutting-edge, patient-specific instruments (PSI) and procedure-specific devices directly at the point of care. Using Formlabs BioMed Durable Resin Form 3, 5L helps improve surgical outcomes, minimize complications, and significantly reduce operating times. This material is ideal for creating robust end-use devices, components requiring strict biocompatibility, and single-use surgical instruments. While Formlabs ensures the material is produced in a certified clean room environment, users are responsible for validating specific designs for their intended clinical application.

Printing with BioMed Durable Resin

Seamless Workflow Integration

Achieving optimal results requires adhering to correct printing protocols to protect your equipment and ensure part quality. Before starting, verify that you are using a resin tank compatible with this material to avoid damage. The workflow begins by installing or updating PreForm, opening your model, and selecting the correct resin version and layer thickness. Once oriented according to the manufacturing guide with generated supports, the print job can be sent to the printer. Remember, the 5L container works in conjunction with a resin pump system for continuous feeding.

Finishing

Precise Post-Processing

Proper washing is essential for maintaining the biocompatibility and mechanical integrity of your prints. The Form Wash system agitates the solvent bath to effectively remove uncured resin. When processing parts printed with Formlabs BioMed Durable Resin Form 3, 5L, pay close attention to the manufacturing guide instructions. If your model features internal channels or hollow sections, ensure that all liquid resin is thoroughly flushed out. Allow the parts to dry completely before moving on to the final curing stage.

Post-curing requirements

Optimizing Material Properties

To unlock the full potential of this material, post-curing is mandatory. This step solidifies the chemical structure, allowing the parts to reach their optimal mechanical strength and biocompatibility status. Refer to the official Form Cure time and temperature settings for precise recommendations. Improper post-curing can lead to suboptimal performance, so following Formlabs' guidelines is crucial for achieving the clearest and most durable results.

Technical Characteristics

- Material Name: Formlabs BioMed Durable Resin Form 3, 5L

- Application: Medical

- Printing Technology: SLA

- Type: Biocompatible

- Ultimate Tensile Strength: 29.1 MPa

- Tensile Modulus: 994 MPa

- Elongation at Break: 33%

- Flexural Strength: 21 MPa

- Flexural Modulus: 643 MPa

- Hardness Shore D: 75D

- Notched Izod: 98 J/m

- Heat Deflection Temp @ 0.45 MPa: 46 ºC

- Recommended Shelf Life: 24 months

- Compatible Printers: Form 3B/3B+, Form 3BL

- Compatible Resin Tanks: Form 3 Tank (all), Form 3L Tank (all)

Purchase the Formlabs BioMed Durable Resin Form 3, 5L at the best price from the online store 3DDevice. As an official representative of Formlabs, we guarantee you receive original products with an official warranty and comprehensive service support. Since 2012, our team of experts has been providing qualified advice to help you choose the right additive manufacturing solutions. We are dedicated to offering professional support before, during, and after your purchase to ensure your medical production runs smoothly and efficiently.