- Stock: In Stock

- Product code: 00-00012565

- Shipping Weight: 6.00kg

Inconel 718 Metal Powder for SLM Printing

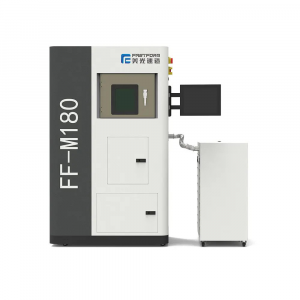

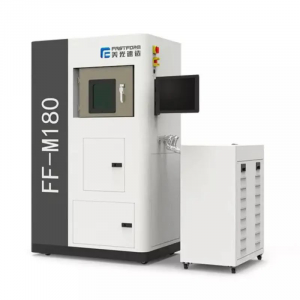

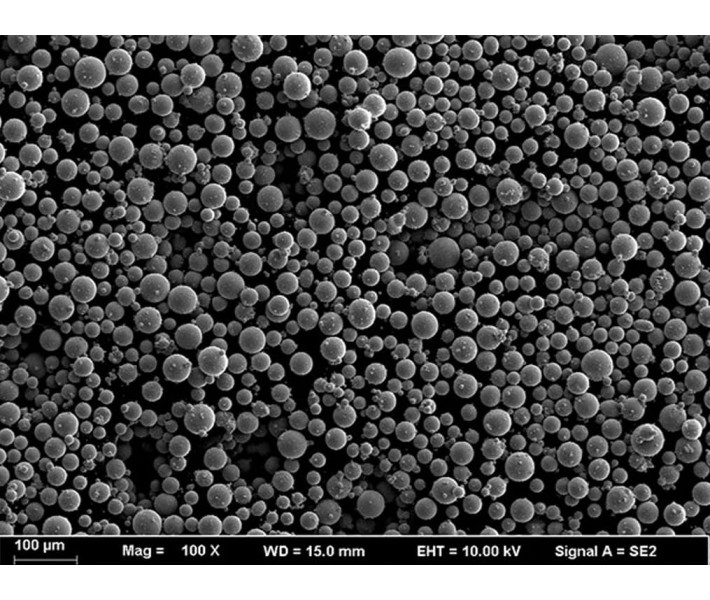

Metal powder FastForm IN718 (Inconel 718) 15–53 μm in 5 kg packaging is a nickel-chromium superalloy designed for professional use in selective laser melting (SLM) systems. The material is characterized by exceptional tensile strength, creep resistance, and corrosion resistance at extreme temperatures (up to 700 °C). Due to its spherical particle shape and stable particle size distribution, this powder is the industry standard for manufacturing high-load components in the aerospace, energy, and oil and gas sectors.

Operational Advantages and Properties of Inconel 718

Thermal and Mechanical Stability

The IN718 alloy belongs to precipitation-hardening materials. Parts made from FastForm IN718 maintain high mechanical performance across a wide range of temperatures. The high nickel and chromium content provides excellent resistance to oxidation and corrosion in aggressive environments. Thanks to low oxygen content (≤200 ppm) and high flowability, the powder guarantees high print density and a minimal number of defects in the metal microstructure.

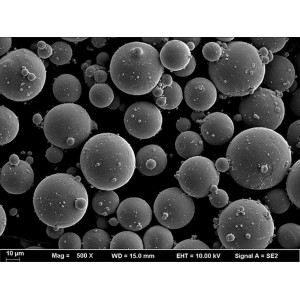

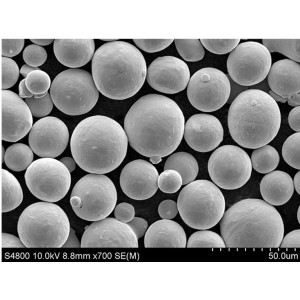

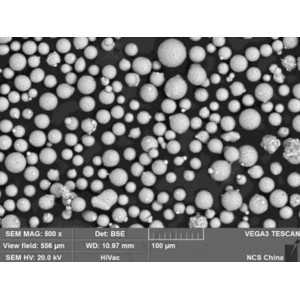

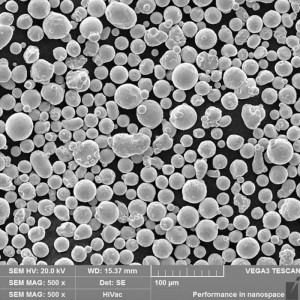

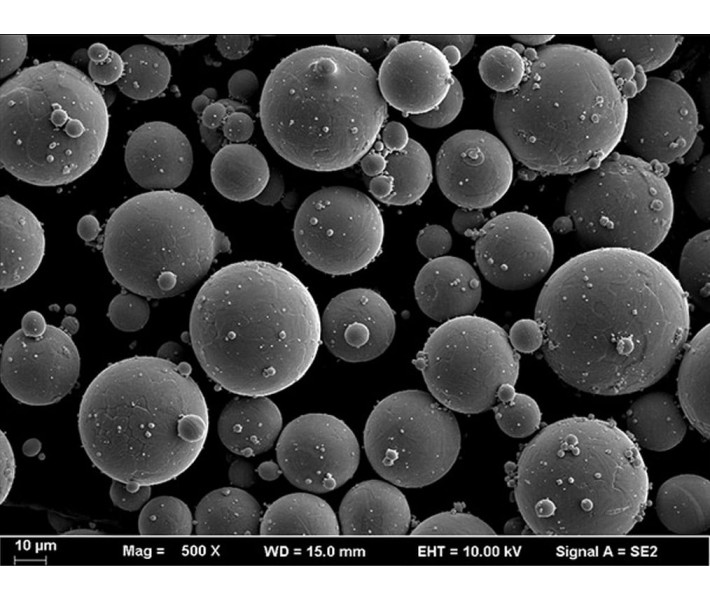

Fraction Precision and Surface Quality

Particle distribution in the 15–53 μm range is optimized to achieve a balance between build speed and surface quality. The spherical morphology of the particles, obtained by gas atomization, ensures high tap density (>4.3 g/cm³) and stable layer deposition by the recoater, which is critical for obtaining leak-proof and durable products.

Technical Specifications of IN718

Chemical Composition (wt. %)

- Nickel (Ni): 50.0–55.0

- Chromium (Cr): 17.00–21.00

- Iron (Fe): Base

- Niobium (Nb): 5.00–5.50

- Molybdenum (Mo): 2.80–3.30

- Aluminum (Al): 0.20–0.80

- Titanium (Ti): 0.65–1.15

- Carbon (C): 0.02–0.06

- Oxygen (O): ≤ 200 ppm

Physical Parameters of the Powder

- Size Range: 15–53 μm

- D10: ≥16 μm

- D50: 30–40 μm

- D90: ≤55 μm

- Hall Flow (s/50g): ≤18

- Apparent Density (g/cm³): >4.3

Applications

FastForm IN718 powder is used for the production of critical components:

- Jet engine and gas turbine components (blades, disks, housings).

- Fasteners and parts for the oil and gas industry operating under pressure.

- Heat exchangers with complex geometry.

- High-strength tools for hot stamping.

Why Choose and Buy FastForm IN718 in Ukraine on 3DDevice

If you plan to purchase FastForm IN718 metal powder in Kyiv or order delivery across Ukraine, 3DDevice offers a professional solution for your production. We have been experts in the field of 3D technologies since 2012 and provide assistance in selecting materials for specific engineering tasks and customer budgets. We ensure high product quality and professional consultations based on years of practical experience in additive manufacturing.