- Stock: In Stock

- Product code: 00-00012563

- Shipping Weight: 6.00kg

FastForm H13: Tool Steel for Complex Tasks

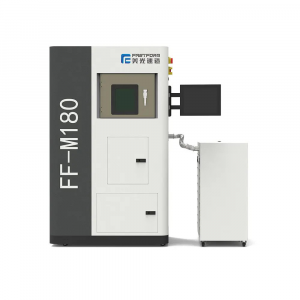

Tool steel FastForm H13 15–53 µm in the form of spherical powder for SLM 3D printing. Available in 5 kg packaging. A specialized material for additive manufacturing using Selective Laser Melting (SLM) technology.

H13 steel (analogous to DIN 1.2344) belongs to the class of hot-work tool steels. It is characterized by high strength, excellent hardenability, resistance to thermal shock, and wear at high temperatures. This material is the standard for manufacturing tooling, molds, and dies operating under severe service conditions. Using FastForm spherical powder allows for the production of complex functional parts requiring high precision and wear resistance.

Resistance to Thermal Fatigue and Wear

A key advantage of H13 steel is its ability to retain high hardness and mechanical properties at elevated temperatures, as well as to resist heat checking (thermal cracking) during cyclic heating and cooling.

High Density and Surface Quality

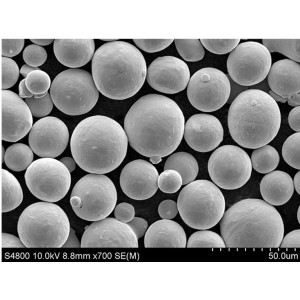

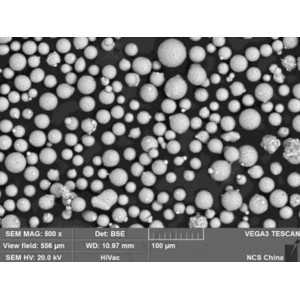

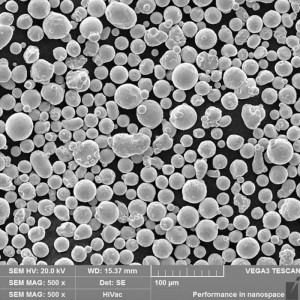

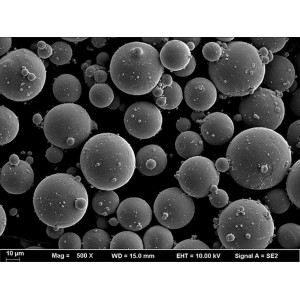

Due to the spherical particle shape and uniform particle size distribution (15–53 µm fraction), FastForm powder ensures high bulk density and stable flowability in the build chamber, which guarantees obtaining dense, non-porous parts with a homogeneous microstructure. Laser melting occurs stably, allowing for parts with a smooth surface and predictable mechanical characteristics after heat treatment.

Optimization of the Casting Process

Using additive technologies with H13 powder allows for manufacturing molds and inserts with integrated conformal cooling channels. This is impossible to achieve with traditional machining methods. Conformal cooling significantly reduces the casting cycle time and improves the quality of final plastic or metal products due to uniform heat dissipation.

Technical Specifications and Applications

- Material. H13 Tool Steel (chromium-molybdenum-vanadium alloy).

- Fraction. 15–53 µm (optimized for SLM printers).

- Particle Shape. Spherical (gas atomization, high flowability).

- Packaging. 5 kg.

- Properties. High hot hardness, wear resistance, good polishability.

Operational Areas of H13 Tools

Due to the ability to 3D print conformal cooling channels directly within the die body, using H13 tool steel powder in 3D printing allows for significantly reducing the casting cycle and increasing tool life. This is critical for the automotive, aerospace, and plastics industries.

- Injection molds for plastics.

- Dies for aluminum and magnesium extrusion.

- Inserts for metal die casting.

- Hot forging and stamping tools.

How to Choose and Buy H13 Tool Steel for 3D Printing in Ukraine

If you need to order or purchase FastForm H13 spherical metal powder in Kyiv or other cities of Ukraine, contact 3DDevice specialists. We have been working in the field of 3D technologies since 2012 and provide expert advice on selecting materials for specific production tasks and budgets. Our many years of experience in 3D technologies allow us to offer only proven solutions and full technical support for your business.