- Stock: In Stock

- Product code: 00-00012566

- Shipping Weight: 6.00kg

FastForm CuCrZr Copper Alloy Powder for 3D Printing

Metal powder FastForm CuCrZr 15–53 μm in 5 kg packaging is a high-tech copper-based material alloyed with chromium and zirconium. This alloy is specifically developed for additive manufacturing using Selective Laser Melting (SLM) technology. By using CuCrZr copper alloy powder for 3D printing, manufacturers gain the ability to create parts with complex geometries that combine high thermal and electrical conductivity with improved mechanical characteristics compared to pure copper.

Technical Advantages and Characteristics of CuCrZr Alloy

High Conductivity and Thermal Stability

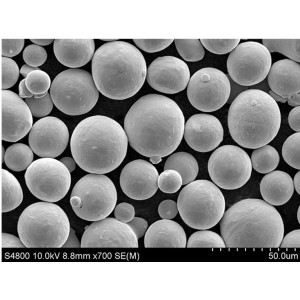

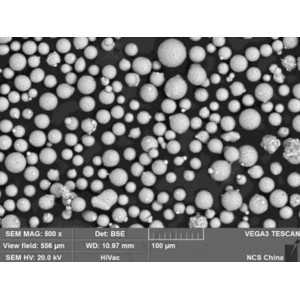

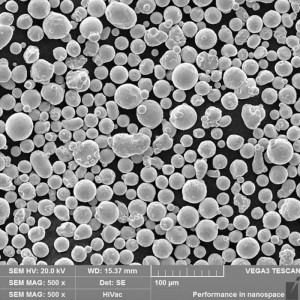

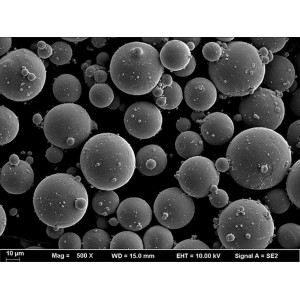

The CuCrZr alloy belongs to the category of precipitation-hardening materials. The addition of chromium and zirconium significantly increases the softening temperature and mechanical strength of the products while maintaining over 80% of the conductivity of pure copper. This makes the material indispensable for manufacturing components operating under conditions of intense heat exchange or high electrical loads. The spherical morphology of the particles, obtained by gas atomization, ensures stable powder flowability, which is critical for achieving a dense metal structure without internal defects.

Parameter Optimization for SLM Systems

The particle size distribution in the 15–53 μm range is selected to ensure high tap density and uniform layer application. Thanks to the controlled chemical composition, FastForm powder demonstrates a stable level of laser radiation absorption, allowing for high repeatability of printing results.

Application Areas and Functional Capabilities

Due to the combination of physical properties, CuCrZr copper alloy powder for 3D printing is used to produce the following components:

- Heat exchangers with complex internal structures and cooling plates.

- Rocket engine elements and combustion chambers.

- Induction coils for induction heating.

- Electrode holders and components for resistance welding.

- Radiators for high-power electronics and power equipment.

The material is heat-treatable (quenching and aging), allowing for the achievement of an optimal balance between hardness and electrical conductivity according to the project's technical requirements.

Why Choose and Buy FastForm CuCrZr in Ukraine on the 3DDevice Website

If you plan to order metal powders in Kyiv or with delivery throughout Ukraine, 3DDevice will provide you with expert support. We have been working in the field of 3D technologies since 2012 and, as specialists, help choose products for specific engineering tasks and customer budgets. Take advantage of our competencies and professional approach to supplying consumables for your additive manufacturing.