- Stock: In Stock

- Product code: 00-00012997

- Shipping Weight: 1.50kg

- SKU: RS-F2-CCCL-01

Buy Formlabs Clear Cast Resin for investment casting

If you have a need to produce cast metal parts for engineering applications in your workshop, consider to purchase Formabs Clear Cast Resin.

This new resin is designed for the direct 3D printing of master molds and patterns for investment casting metals with wall thicknesses over 3 mm. The material has extremely low thermal expansion, low ash content and no traces of heavy metals, making it ideal for casting engineering parts.

This 1 liter Clear Cast Resin cartridge is specifically designed for 3D printing on Formlabs Form 3 series printers.

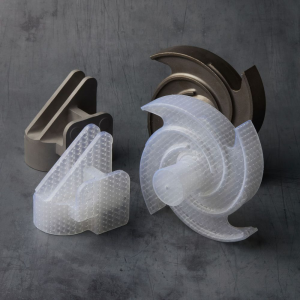

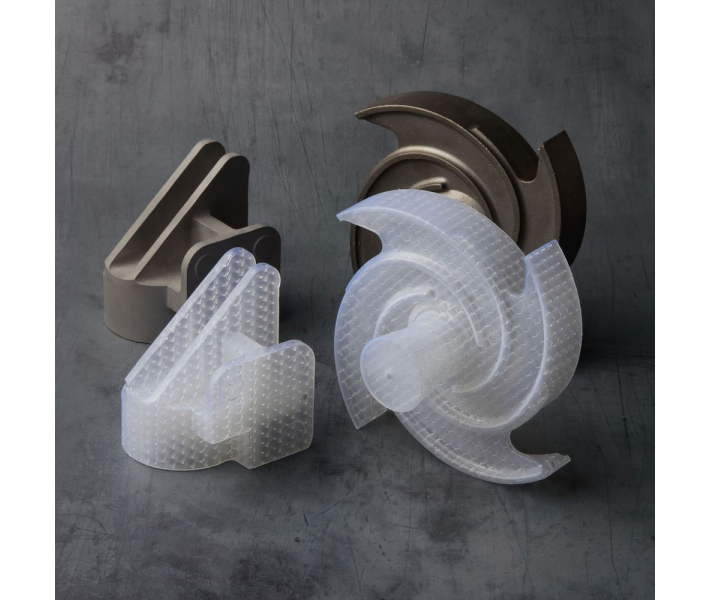

Clear Cast Resin is recommended for use with larger parts in combination with the lattice creation software, which allows for geometries with a thickness of more than 3 mm.

Investment casting using 3D printed patterns

- In-house production of patterns at an affordable price. This Clear Cast Resin cartridge allows you to directly produce metal casting patterns on Formlabs Form 3 Series 3D printers in-house, reducing costs, shortening lead times, and improving iteration and production flexibility.

- Clean burn-in. The clear cast resin provides a clean burn with low ash content and no trace of metals, leaving nothing to contaminate the final molded part.

- Low thermal expansion. Best-in-class thermal expansion for reliable casting shells with minimal cracking.

- Precise and versatile. Create accurate models within 0.25 mm of the design. Compatible with any metal or shell system, enabling foundries to cast new designs in record time

- Built on experience. Formlabs manufactures industry-leading resins for third-party large SLA printers in its state-of-the-art Ohio facility and uses this experience to develop Clear Cast Resin for its own SLA printers.

Application of Clear Cast Resin for metal casting

Today, investment casting is used in many industries that require individual production of precision metal parts: engine parts, turbines, medical implants, surgical instruments, dental prostheses, jewelry, souvenirs and decorative elements, various complex components for industry, etc.

3D printing of fired patterns for metal casting

Investment casting is a manufacturing process in which liquid material is poured into a ceramic mold containing a cavity of the desired shape and then allowed to solidify.

It is an ancient method of producing metal parts that allows for the production of complex shapes and high precision products and has reached a new level of development thanks to modern technology. Die casting is time-consuming and expensive for small runs or prototypes.

How does 3D printing help to cast precision metal products?

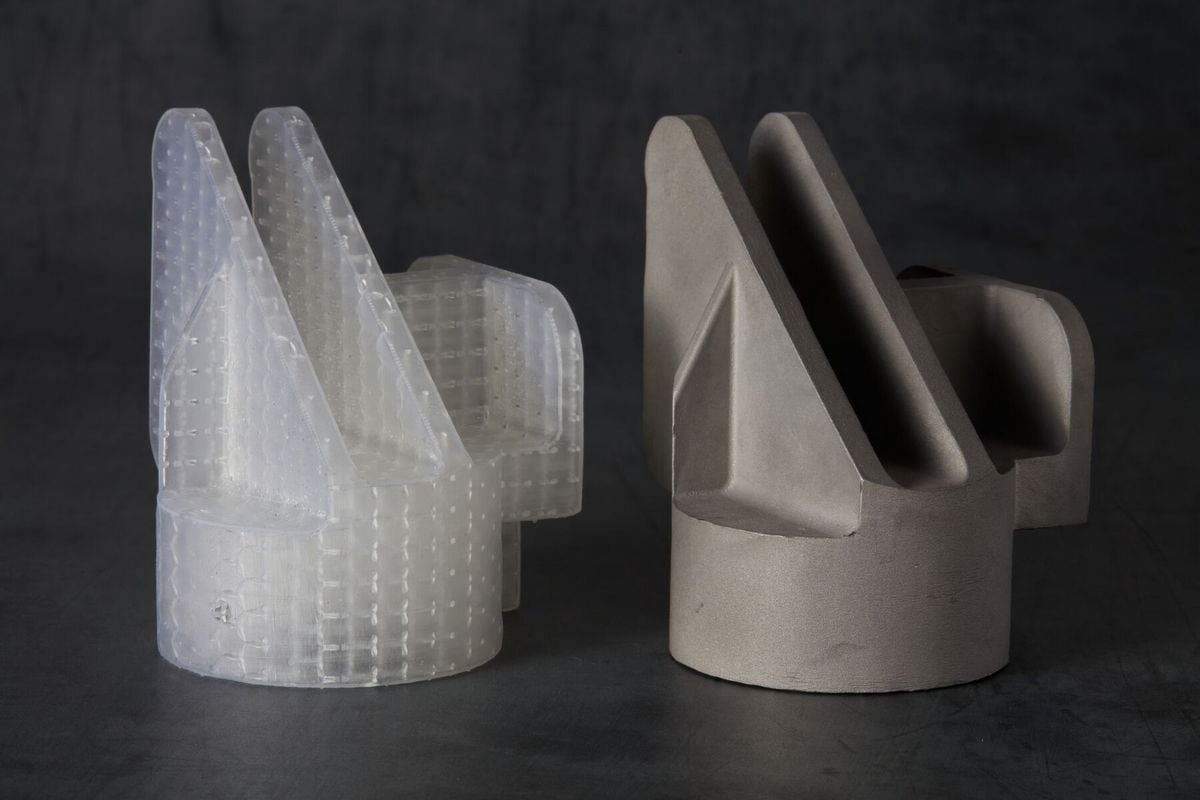

The main idea behind the innovation in metal investment casting is to 3D print an exact copy of the future part. The traditional way to produce such a copy was to create it from wax, which was quite labor-intensive.

The 3D printed template is then covered with a refractory material, such as ceramic. After the refractory mixture has hardened, the printed template is melted, forming a cavity of the exact shape of the part. Molten metal is poured into this cavity, filling the entire space and taking the shape of the template. After cooling and removal of the casting system, the finished product is obtained.

Formlabs burnable Resins comparison

The Formlabs material library already contains burnable resins for printing metal casting molds and patterns. These are Castable Wax and Castable Wax 40. What is the difference between them?

Use Formlabs burnable materials for the following cases:

- Castable Wax – for printing patterns for lightweight jewelry.

- Castable Wax 40 – for printing more massive metal casting molds with a wall thickness of up to 3 mm.

- Clear Cast – printing molds with a thickness of more than 3 mm, suitable for most engineering applications.

Workflow for 3D printing of casting patterns from models

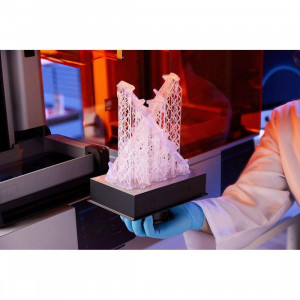

3D printed molds or templates can be used to directly replace molded wax patterns commonly used for investment casting, allowing for complex geometries and faster iterations without special tools. The process of creating a 3D printed pattern is usually as follows:

- Create shells, mesh, and add drainage holes to the part using a tool like Materialize Magics or Formware.

- Orient the supports and cut the model in PreForm.

- Print the template.

- Wash, refine, and remove the supports.

- Seal any drainage holes with wax or apply a small amount of Clear Cast resin to the hole.

- Attach the pattern to the casting tree and continue the casting process.

Clear Cast Mechanical and Burnout Properties

- Ultimate Tensile Strength – 65 MPa

- Tensile Modulus – 2.8 GPa

- Flexural Modulus – 2.2 GPa

- Thermal Expansion, -30-140°C – 94.8 μm/m/°C

- Ash Content – <0.20%

- Antimony – <10 ppm

- Detected Transition Metals (>10 ppm) – Al, Cu

- High Concentration Transition Metals (>50 ppm) – None

Downloads

Technical Data Sheet, PDF (EN)

Buy Formlabs Clear Cast Resin in Ukraine

If you have any questions, please contact us.