- Stock: In Stock

- Product code: 00-00013663

- Shipping Weight: 80.50kg

Unlock the full potential of automated quality control with the SHINING 3D RobotScan Q12. This intelligent robotic system is engineered to revolutionize how manufacturers approach 3D inspection, offering a seamless transition from manual measurements to fully automated precision. Designed for modern production environments, this solution ensures that your geometric data is captured rapidly and accurately, streamlining the path from physical part to detailed analytical report.

Automated Precision with SHINING 3D RobotScan Q12

Streamlined Industrial Metrology

The SHINING 3D RobotScan Q12 is part of a sophisticated series developed to enhance inspection efficiency significantly. By replacing traditional manual operations with robotic automation, the system guarantees a standardized 3D scanning process that eliminates human error. It is capable of performing rapid operational checks directly on the production line, automatically generating comprehensive reports that help maintain the highest quality standards in intelligent manufacturing.

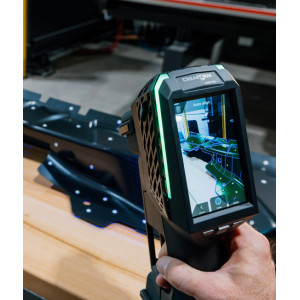

Structured Light Excellence

At the core of this configuration is the integration with high-precision structured light technology. The system utilizes the OptimScan Q12 sensor, which provides exceptional resolution and stability. This makes the SHINING 3D RobotScan Q12 particularly suitable for industries requiring meticulous detail, such as the production of electronic components, precision electromechanical parts, and civil aviation equipment. Every scanner used in the system undergoes rigorous calibration in a CNAS-accredited laboratory (ISO 17025), ensuring reliable measurement accuracy you can trust.

Advanced Software and Workflow Integration

Seamless Data Management

The power of the SHINING 3D RobotScan Q12 lies in its robust software ecosystem. The RobotScan Control software acts as the central hub, offering an intuitive, process-oriented interface that manages the collaborative robot, servo-turntable, and scanner simultaneously. From planning the robot's trajectory to executing the scan, the workflow is smooth and easy to master. Furthermore, the system integrates effortlessly with MES systems, allowing for secure data management and traceable quality control processes.

Certified Inspection Tools

Data analysis is handled by SHINING3D Inspect, a professional metrology software package certified by PTB for accuracy. This tool processes the high-density 3D point clouds captured by the scanner to perform detailed geometric comparisons and measurements. Whether you need to verify dimensions against CAD models or generate automatic pass/fail reports, the software delivers valid, traceable results that meet the strict requirements of modern quality management systems.

Technical Specifications

- System Name: SHINING 3D RobotScan Q12

- Compatible Scanner: OptimScan Q12 (Structured Light)

- Robot Type: Han’s Robot Cobot (Working radius 800 mm)

- Dimensions: 1030 × 670 × 270 mm

- System Weight: 70 kg

- Measurable Object Size: Up to 500 mm

- Turntable Load Capacity: 20 kg

- Safe Working Zone: 2400 × 2400 × 1600 mm

- Installation Type: Desktop / Floor

- Power Supply: 100 – 240 V (Single phase, 10 A)

- Power Consumption: Rated 135W (Peak 260W)

- Data Connectivity: Ethernet 2.5G, USB 3.0

- Working Temperature: 0 – 40 °C

Buy SHINING 3D RobotScan Q12 at 3DDevice

To integrate the SHINING 3D RobotScan Q12 into your production line, choose 3DDevice as your trusted partner. We are experts in the additive manufacturing and 3D metrology market with experience dating back to 2012. Our team provides professional advice to help you choose the right configuration and offers qualified support before, during, and after your purchase.

As an official representative of SHINING 3D, we guarantee the best price on the market, full official warranty coverage, and certified service support. Trust us to deliver a solution that meets your industrial standards.