- Stock: In Stock

- Product code: 00-00013471

- Shipping Weight: 1.30kg

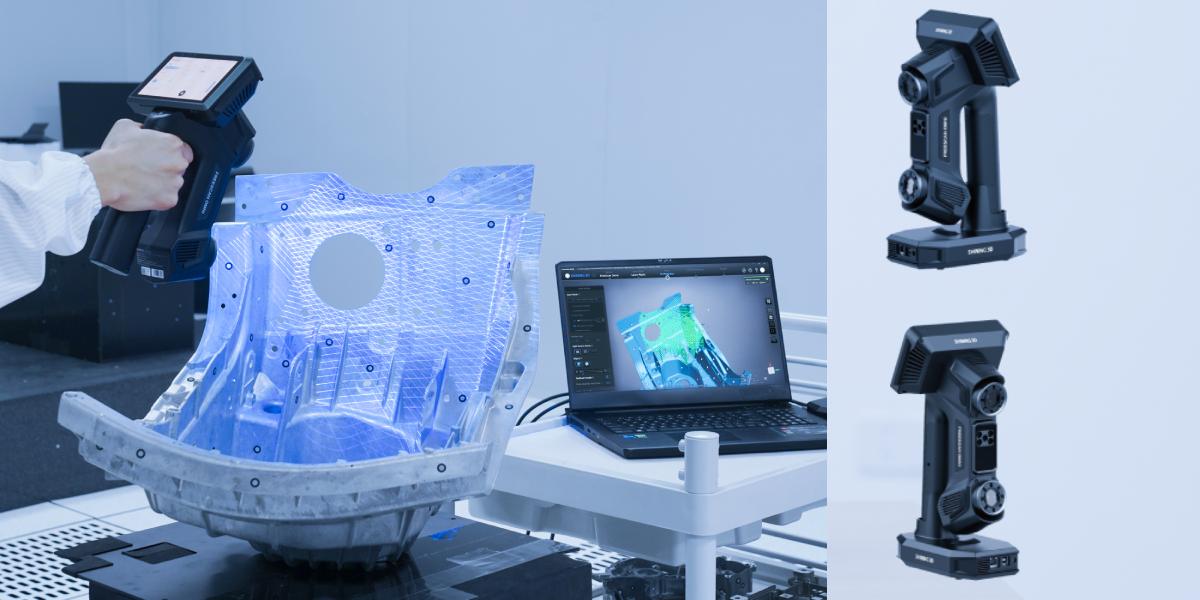

SHINING 3D FreeScan Omni – 91 Laser Line for Fast Scanning

The SHINING 3D FreeScan Omni 3D scanner is an advanced professional solution for three-dimensional capture and inspection: a light (≤ 1.1 kg) wireless handheld scanner with high accuracy (0.02 mm) and built-in analysis and reporting tools. It allows real objects to be efficiently converted into a digital model with maximum speed and reliability, combining industrial requirements and workflow mobility. The high quality of the hardware and the large screen allow not only fast scanning, but also autonomous processing of digital copies. The SHINING 3D scanner will significantly increase the speed and quality of processing even complex and large surfaces.

Technical Parameters

The key technical parameters of the FreeScan Omni allow it to be referred to as a true metrology-inspection system:

- Scanning accuracy: 0.02 mm.

- Volumetric accuracy = 0.02 + 0.03 mm/m.

- When using built-in videophotogrammetry (VPG) — volumetric accuracy = 0.02 + 0.015 mm/m.

- Scanning speed up to 7,619,000 points/sec.

- Maximum field of view (FOV) by laser = 580 × 650 mm.

- Depth-of-field = 170 … 1000 mm (works up to ~830 mm effective area).

- Works in wireless and wired mode, removable battery packs.

- Device weight ≤ 1.1 kg.

- Multiple scanning modes: high-speed (93 laser lines), detailed scanning mode (25 parallel lines), deep pocket mode (1 line), IR-mode without markers.

- Compatibility with leading software: Geomagic Control X, PolyWorks, Geomagic Design X, and others.

Features and Advantages compared to other SHINING 3D models

The advantages of the FreeScan Omni stand out against previous SHINING 3D models (for example, FreeScan Combo, UE series, and others):

- Wireless Control – unlike many analogues in this series, the device allows working without constant connection to a computer, which increases convenience on production sites or during on-site inspection.

- Integrated Videophotogrammetry (VPG) eliminates the need for coded markers, which significantly speeds up preparation for scanning large objects.

- High Speed and Wide Range of Modes (93 lines, 25 lines, 1 line, IR) provide versatility: it can cover both large-scale objects and complex areas with fine geometry.

- Metrology-Calibrated Accuracy (certified according to VDI/VDE 2634 Part 3 standard, ISO 17025 certified laboratory).

- Light Weight (≤ 1.1 kg) and Mobility make the device comfortable for long manual work, unlike heavier stationary systems.

- Full Cycle «Scanning → Point Cloud → Inspection → Report» is implemented directly on the device or with minimal PC support, which reduces data processing time.

Areas of Use FreeScan Omni

The FreeScan Omni is most appropriate where a combination of mobility, high precision, and speed is required.

- Automotive Industry: body surface inspection, deformation repair, reverse engineering of parts.

- Mechanical Engineering and Heavy Industry: inspection of assemblies, large-sized components, equipment, where fast on-site measurement is important.

- Energy and Infrastructure: scanning of machines, turbines, metal structures located remotely.

- Manufacturing and Quality: inline inspection, geometric verification of parts, comparison with a CAD model.

- Education and Research Centers: where a universal solution is needed for scanning objects of various formats.

For which tasks is the SHINING 3D FreeScan Omni suitable?

- Fast digitalization of large-sized objects with high accuracy (e.g., car body, machine base).

- Inspection and comparison with a reference CAD model: identification of deviations, control of dimensions, vertical/horizontal gaps.

- Reverse Engineering: obtaining a point cloud, exporting STL/OBJ formats, and further processing.

- Quality Control in Series Production: measurement of large batches with minimal setup and preparation.

- On-site, field work: mobile mode, battery operation, wireless connection.

Brief Recommendations for using FreeScan Omni

- Before scanning, ensure that the object's surface is prepared (strong reflections are eliminated if possible, and a matte finish is applied if necessary).

- Select the appropriate scanning mode: high-speed for general shape, detailed mode for intensive geometry, 1-line mode or IR-mode for narrow/deep areas.

- For a large object, enable VPG mode and use a calibration bar for maximum volumetric accuracy.

- Control the distance to the object (recommended depth of field 170–1000 mm) and the sensor position to ensure an optimal field of view.

- Use compatible software for point cloud processing, report generation, and integration with the CAD/CAx system.

- Ensure sufficient power: for long battery operation, replace batteries in advance to avoid downtime.

- Store and maintain the device according to the manufacturer's recommendations, including periodic calibration, to maintain stated accuracy.

Technical Specifications SHINING 3D FreeScan Omni

| Parameter | Value |

|---|---|

| High-Speed Scanning | Included (93 laser lines) | VCSEL |

| Detailed Scanning | Included (25 parallel laser lines) |

| Deep Pocket Scanning | Included (1 laser line) |

| VPG | Included (coded markers not required) |

| Accuracy | 0.02 mm |

| Volumetric Accuracy | 0.02 + 0.03 mm/m |

| Volumetric Accuracy Expansion with VPG | 0.02 + 0.015 mm/m |

| Scanning Speed | 7,619,000 points/s |

| Resolution | 0.01 ~ 10 mm |

| Max. Field of View | Laser: 580 x 650 mm; IR: 1205 x 1104 mm |

| Connection | Wireless and Wired Mode |

| Depth of Field | 830 mm (170 ~ 1000 mm) |

| Net Weight | ≤1.1 kg |

| Certifications | CE, FCC, ROHS, WEEE, KC, FDA, UKCA, IP50, TELEC, TiSAX |

| Acceptance Test | VDI/VDE 2634 Part 3 (certified in an ISO 17025 certified accuracy laboratory) |

Video review of the SHINING 3D FreeScan Omni

The FreeScan Omni 3D scanner from SHINING 3D is a high-precision, mobile, universal solution for professional three-dimensional scanning and inspection. If you are looking for a tool that will provide reliable measurements, speed up workflows, and expand the capabilities of your production or research activities, we recommend reviewing the detailed specification, contacting our managers for consultation, and choosing the optimal equipment.