- Stock: In Stock

- Product code: 00-00012931

- Shipping Weight: 5.00kg

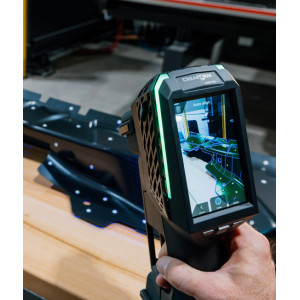

Industrial 3D Scanner with Automatic Calibration Revopoint Optical Tracking

Revopoint Trackit is an optical 3D scanner that allows for scanning without using markers. The device is equipped with 30 blue cross lasers. They provide high-speed scanning even for very large objects. A single laser line is provided for deep holes in the scanner. The Revopoint Trackit scanner is capable of working with objects of different sizes. It scans both small parts from 10 mm and large objects up to 6 meters.

![]()

Professional Accuracy and Detail

The scanner provides a volumetric accuracy of 0.02 mm + 0.04 mm x L(m). This characteristic guarantees precise results. Revopoint Trackit excels at scanning small details. It captures gear teeth, deep holes, crevices, and recesses. The created 3D models are suitable for quality control. They can also be used for reverse engineering.

Flexibility and Ease of Use

Revopoint Trackit supports two operating modes. It can work in optical tracking mode. Autonomous manual scanning is also available. This allows it to adapt to different conditions. You can easily scan hidden or internal areas. These zones are usually inaccessible to the base station. Trackit's autonomous functions make this possible.

![]()

Saving Time and Resources

The scanner works without markers. This feature helps save time. The device uses advanced optical tracking technology. It tracks the scanner's position in real-time. Thus, the scanner obtains accurate 3D data. The Trackit base station is equipped with two cameras. This increases the efficiency of 3D scanning. It works with parts from 10 mm to 6 meters in size.

![]()

Scanning Large Objects in Factory Conditions

You can easily scan large parts. To do this, you need to move the Revopoint Trackit base station around the object. It quickly scans the surface at a speed of up to 1.5 million measurements per second. The system of reference blocks ensures flawless stitching of frames. This allows you to create professional 3D models. The adjustable tripod makes the scanner setup simple. This allows it to adapt to various shooting conditions. The maximum tracking frame area is 2800 × 2800 mm at a distance of 4000 mm. The tracker's working distance varies from 1.5 to 4 meters. The device is equipped with a 6-meter cable. This makes it maneuverable.

Automatic Calibration Optical Tracking

The calibration process is fully automated. This saves the user time and effort. The scanner performs multi-position calibration itself. This eliminates the human factor. The intelligent two-axis gimbal system provides high accuracy. The calibration process becomes reliable and simple.

![]()

Durable Construction: High-Quality Industrial 3D Scanner Revopoint

The scanner has a durable frame made of carbon fiber. It is solid. This provides stable scanning data. The frame eliminates errors caused by deformation or marker displacement. The design is strong, yet lightweight. This makes long-term scanning comfortable.

Realistic Texture Display

The device is equipped with a high-resolution RGB camera. It captures the texture of the object's surface. This allows for creating vivid 3D models. Texture data can be used with the Revo Measure program. This is needed for precise measurements.

![]()

Software for Revopoint Trackit Optical Tracking

Revo Trackit is a simple and free software. It is designed for scanning, editing, and calibration. The program supports various file formats. Among them are PLY, OBJ, STL, ASC, 3MF, GLTF, FBX.

Detailed Scanning Settings

The program allows you to control every aspect of the process. This ensures optimal point cloud capture. Real-time point cloud monitoring helps to ensure that enough data has been collected.

![]()

Revo Design

Revo Design software is identical to QUICKSURFACE Lite. It helps convert scanning data into CAD. The program is equipped with tools for editing meshes. It also supports freeform and parametric modeling. Revo Design is ideal for reverse engineering and industrial design.

Revo Measure

The Revo Measure program allows you to compare point clouds or meshes with CAD data. It has tools for high-precision measurements of models. It also extracts parameters. The program measures volume and analyzes geometric dimensions.

![]()

Contents of the Optical Tracking Scanner Kit*

- Scanner

- Tracker

- Tracker tripod

- Automatic scanner calibration, two-axis gimbal.

- Automatic tracker calibration, two-axis stabilizer

- Calibration board × 1

- Calibration pole

- Tripod for the calibration board

- Tripod for the scanner

- Power adapter

- PC cable

- Scanner cable

- Scanner gimbal cable

- Tracker gimbal cable

- Cable ties

- Marker × 20 (magnetic)

- Anchor block × 8 (magnetic)

- Positioning pad

- Scanner adapter

- USB flash drive

- Tracker case with wheels

- Scanner case on wheels

*The manufacturer may change the appearance, characteristics, and contents of the product without notice. Please clarify the contents of the box with the manager when placing your order.

You can choose an industrial scanner with a tracker for production yourself on the website, in the 3D scanners category. If you need more information, all contact channels are available on the "Contacts" page: write, call – we are always happy to help!

Video review of Revopoint Trackit Optical Tracking